Microscopic heat distribution test method and system

A test method and heat distribution technology, applied in the field of microscopic heat distribution test methods and systems, can solve the problems of inaccurate test results, complicated test process, poor data and heat distribution image processing capabilities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

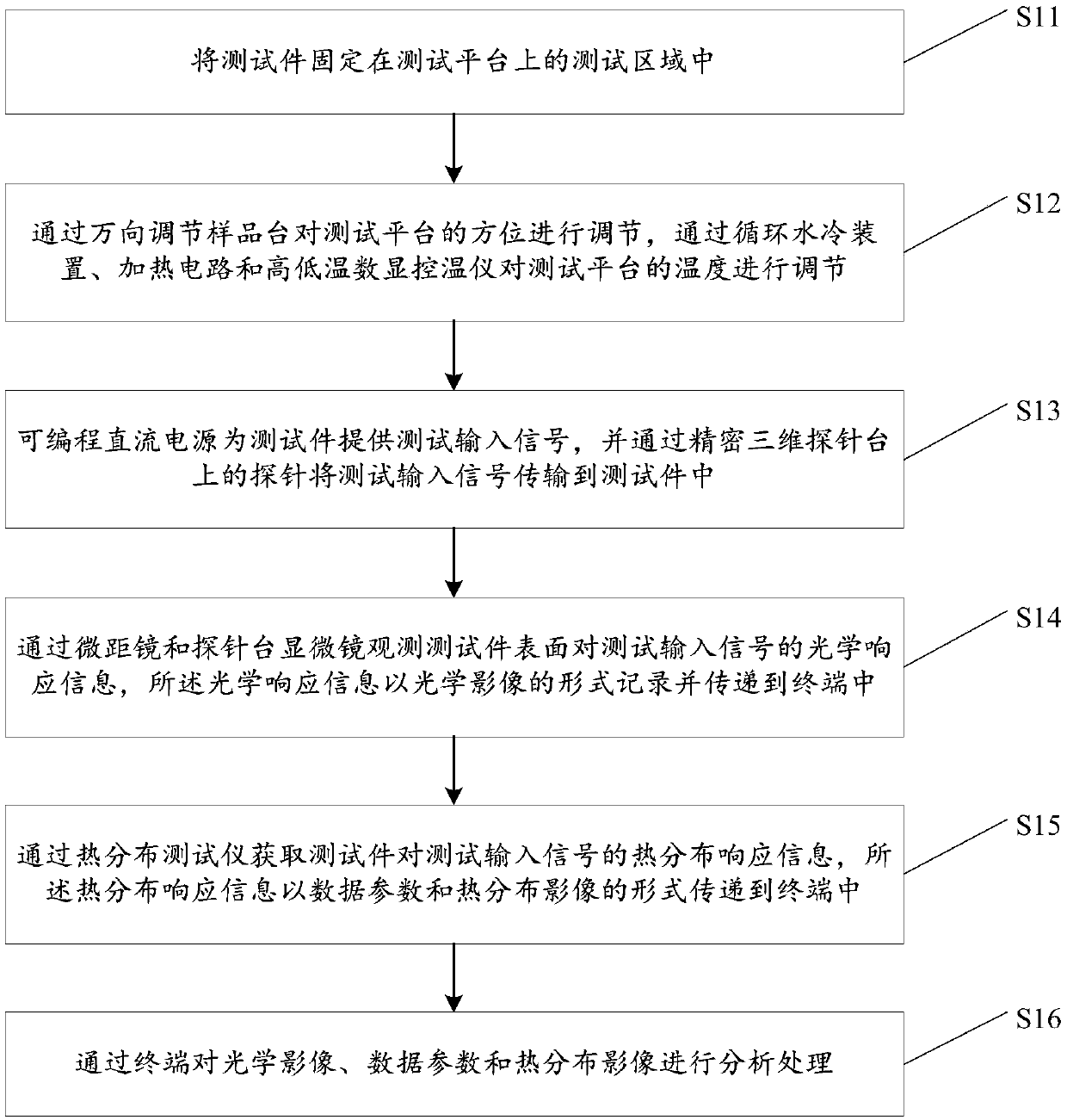

[0050] see figure 1 , figure 1 It is a schematic flow chart of a microscopic heat distribution testing method in an embodiment of the present invention.

[0051] like figure 1 Shown, a kind of microthermal distribution testing method, described method comprises:

[0052] S11: Fix the test piece in the test area on the test platform.

[0053] Specifically, the test platform is provided with a test area, and the surface of the test area is covered with a layer of magnets. When the test piece contains ferromagnetic substances such as iron, nickel, cobalt and other metals, the test area can attract the test piece so as to The test piece is fixed; in addition, the test platform is also provided with a test piece fixing device, when the test piece cannot be absorbed by the magnet on the surface of the test area or needs to be further fixed, the test piece can also be fixed by the test piece fixing device .

[0054] S12: Adjust the orientation of the test platform through the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com