A multi-energy medium comprehensive optimization and allocation system based on energy simulation for iron and steel enterprises

An energy medium, multi-energy technology, applied in the direction of constraint-based CAD, design optimization/simulation, special data processing applications, etc., can solve the problem of difficult to obtain comprehensive optimization of various energy media, energy-medium balance relationship, and optimization constraints. , can not consider the relationship between various energy media and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

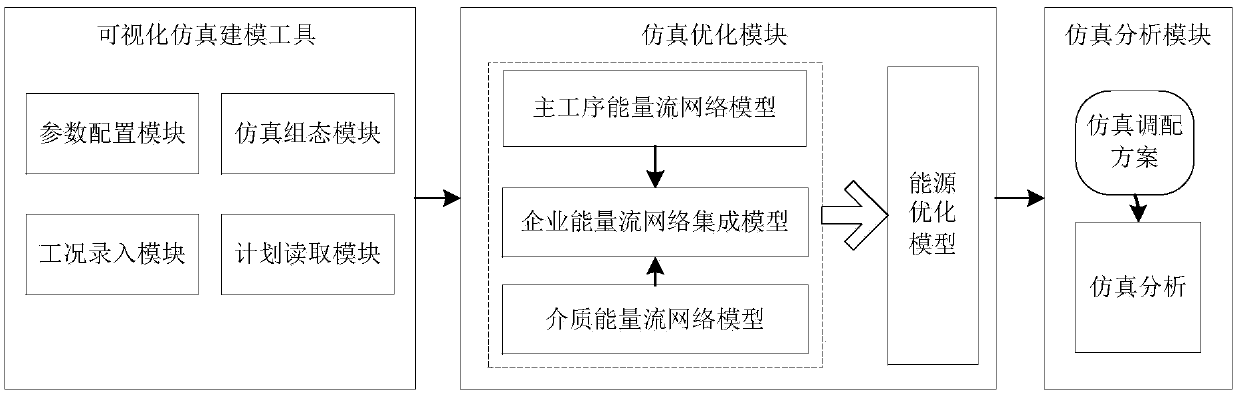

[0074] The present invention includes: a simulation configuration module, a parameter configuration module, a working condition entry module, a plan reading module, a simulation optimization module, and a simulation analysis module. Stored in a relational database, the relational database software runs on a database server, and the simulation computer and the database server are linked through a local area network. The functional structure diagram of this system is as follows: figure 1 shown.

[0075] 1. If figure 1 As shown, start the visual simulation modeling tool, first perform simulation configuration, configure the simulation unit and energy flow network structure, and then configure the discount factor configuration, cache configuration, fuel constraint, equipment capacity constraint, and medium priority through the parameter configuration module Configuration and self-consumption coefficient configuration provide basic data for the simulation optimization model, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com