A new type of cutting tobacco processing technology for tobacco

A processing technology and a technology for shredded tobacco are applied in the field of new tobacco shredded tobacco processing technology, and can solve the problems of large fluctuation in the weight of cigarettes, unfavorable cigarette quality control, insufficient application amount of atomizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

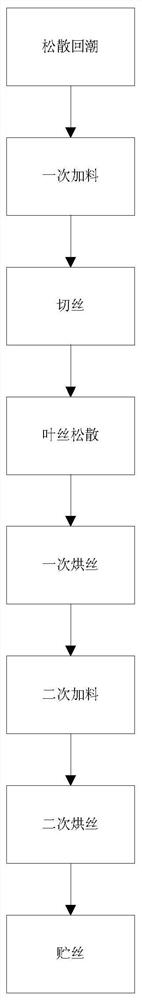

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: with certain cigarette factory stock tobacco leaf as the processing raw material of cutting tobacco for novel tobacco, its concrete process step is as follows:

[0031] (1) After the tobacco leaves are loosened and rehydrated through the existing unpacking and slicing processes, the moisture content of the tobacco leaves is ≤14%, the temperature of the tobacco leaves is 70°C, and the loosening rate of the tobacco leaves is ≥98%;

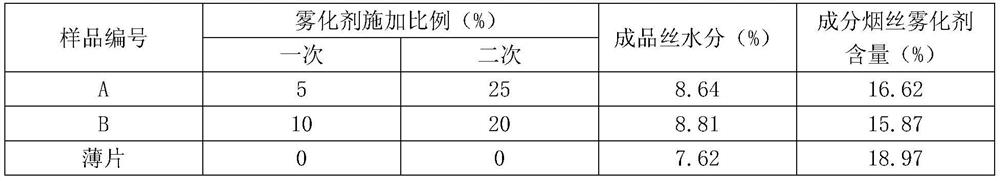

[0032] (2) Put the loose tobacco leaves that have been loosened and regained moisture in step (1) into a cylinder wall heating type drum feeder for feeding, and the feeding method adopts the method of air injection, without applying steam and without increasing the moisture content of the raw material. The applied atomizing agent is a mixture of propylene glycol and glycerin; the temperature of the barrel wall of the feeding machine is 90° C., and the application amount of the atomizing agent is 5% of the weight of the tobacco lea...

Embodiment 2

[0038] The technological process of Example 2 is the same as that of Example 1, the proportion of atomizing agent applied for the first time is 10%, and the proportion of atomizing agent applied for the second time is 20%, so as to prepare shredded tobacco B for novel tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com