Auxiliary robot system for ophthalmic microsurgery

A robotic system and microsurgery technology, applied in surgical robots, surgical manipulators, etc., can solve the problems of poor surgical operation accuracy and stability, and achieve the effect of eliminating physiological tremor, improving accuracy and stability, and eliminating jitter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

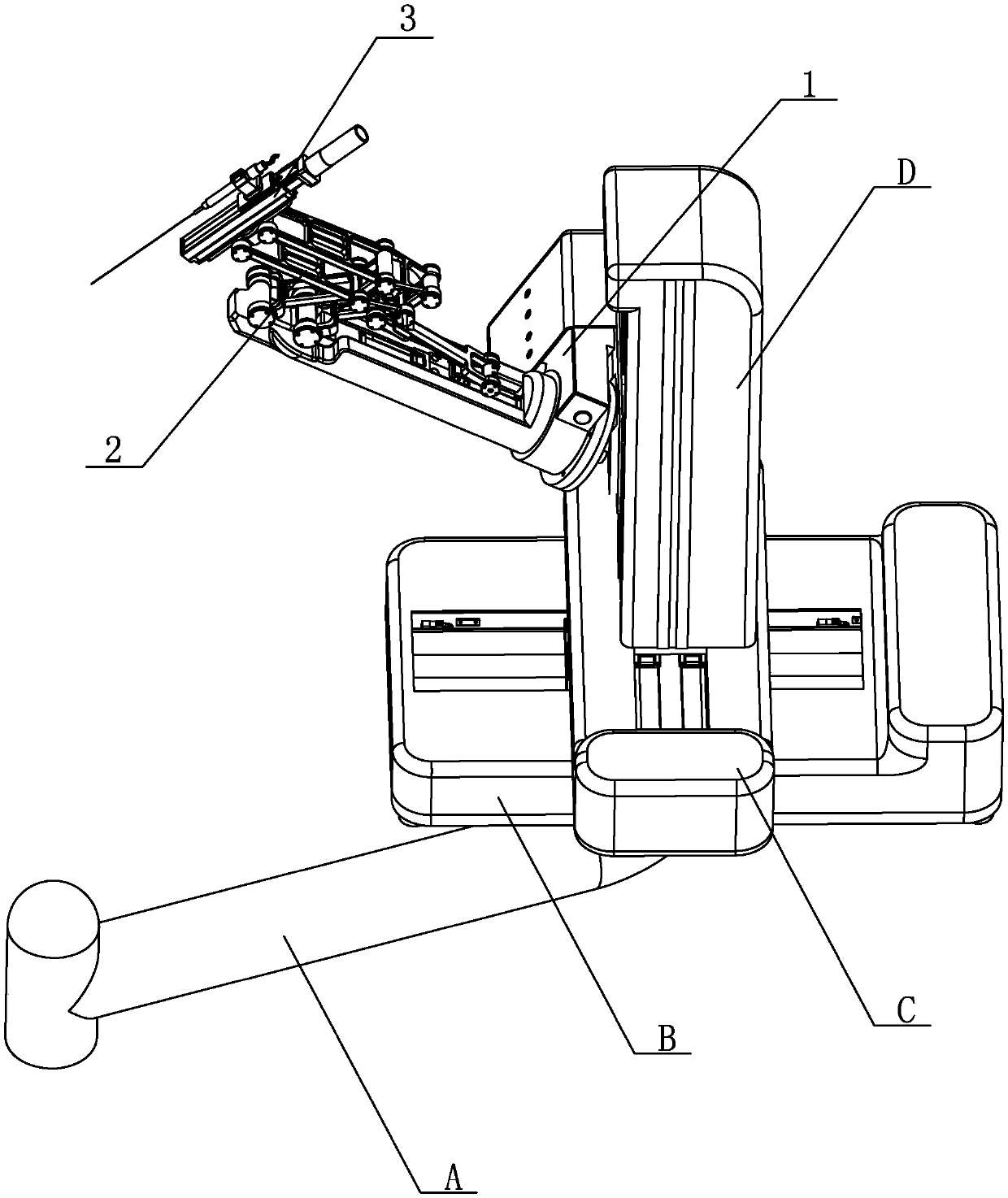

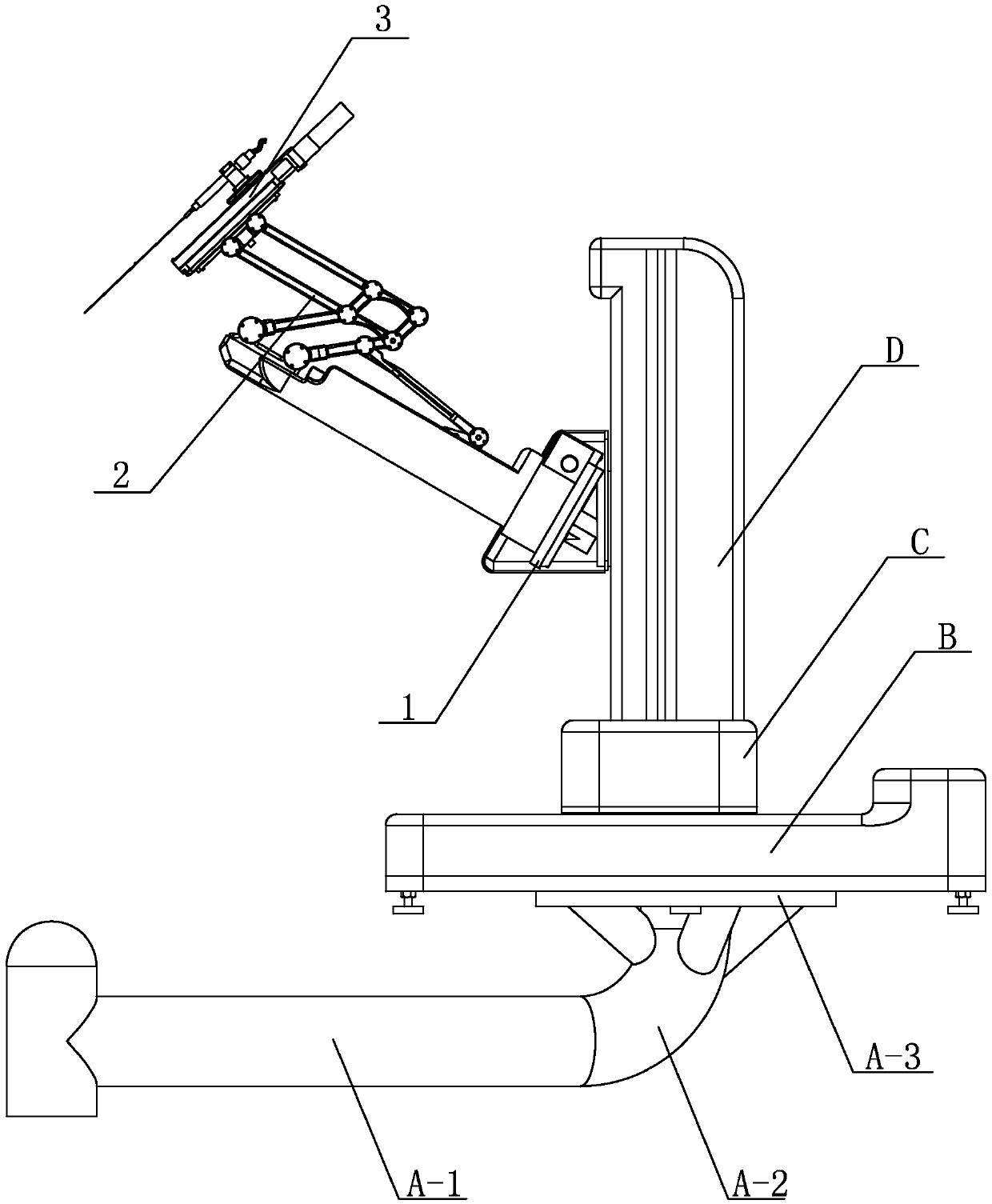

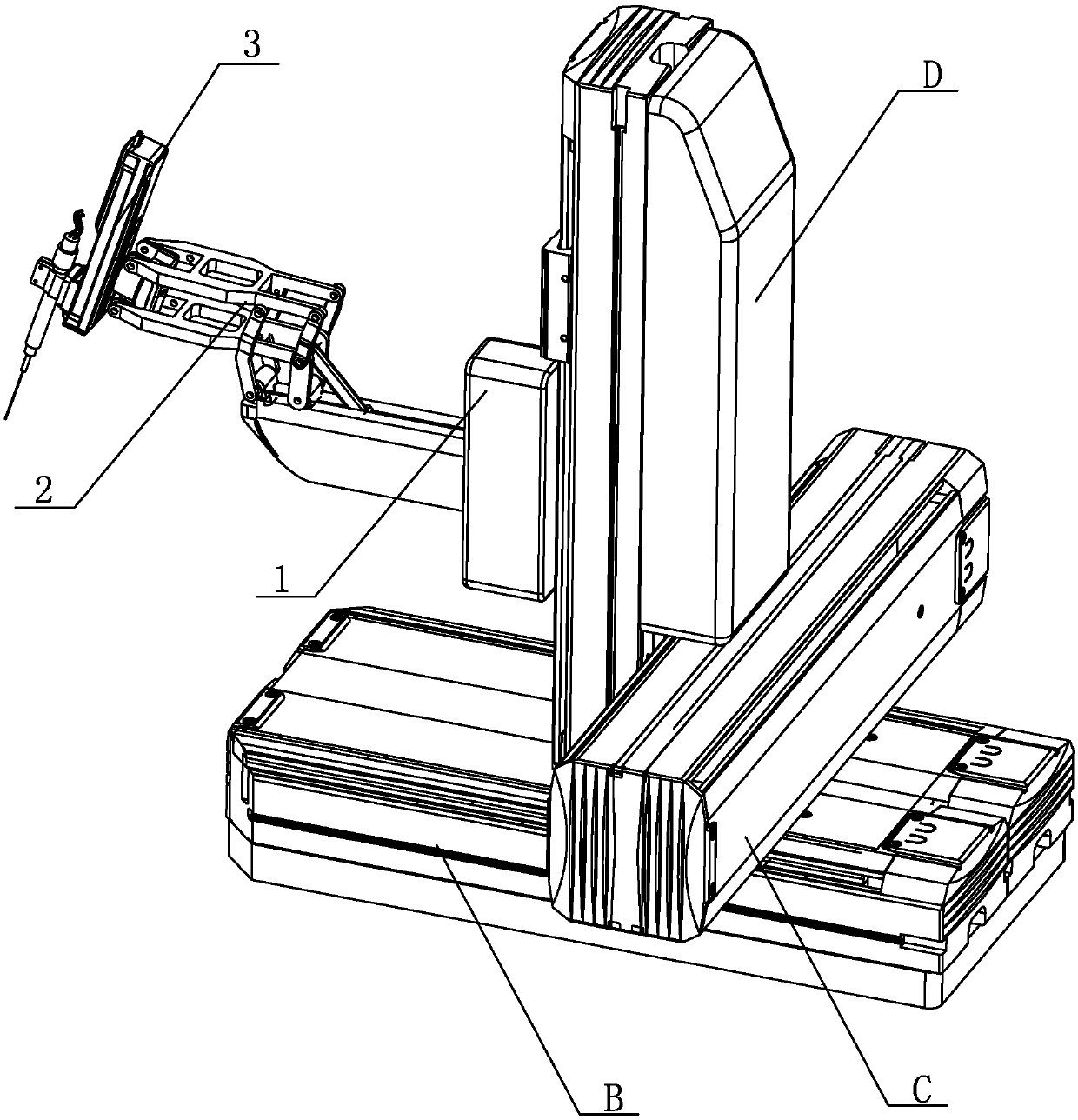

[0016] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a kind of ophthalmic microsurgery auxiliary robot system of this embodiment, it comprises main operating table 6, and main operating table 6 is installed on the workbench, is characterized in that: it also comprises 3D video microscope device 7, The dual-arm robot 8 and the foot switch 9, the main operating table 6 is located between the dual-arm robots 8, and the lower part of the main operating table 6 is connected to the base of the dual-arm robot 8 as a whole, and the 3D video microscope device 7 is hoisted above the middle part of the double manipulator robot 8, and the foot switch 9 is connected to the 3D video microscope device 7 and the double manipulator robot 8 through a flexible cable and drag chain;

[0017] The double manipulator robot 8 includes a main manipulator and a secondary manipulator, and the main manipulator and the secondary manipulator are arranged symmetri...

specific Embodiment approach 2

[0033] Specific implementation mode two: combination Figure 4 Describe this embodiment, the rotating module 1-1 of this embodiment comprises motor, transmission device, worm and worm wheel, the output end of motor is connected with transmission device, the output end of transmission device is connected with worm wheel, and worm screw is installed on the cantilever 1-3 Inside, and the worm meshes with the worm gear. In actual use, the manufacturer of the rotation module 1-1 is R150M produced by Parker. Such arrangement drives the rotation of the entire cantilever 1-3 around the cantilever axis; the connection method is simple and reliable, and other components and connection relations are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Specific implementation mode three: combination figure 1 To describe this embodiment, the model of the cantilever linear guide module 1-4 in this embodiment is KK40-01P-150A-F2ES2 (PNP). With such arrangement, the stroke is large, the production is convenient, and the cost is low. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com