Isolating agent continuous production device and control system thereof

A production device and production control technology, applied in chemical/physical/physical-chemical stationary reactors, etc., can solve the problems of not having the temperature required for the reaction, incoherent dilution operation, long reaction time, etc., saving manpower and equipment Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

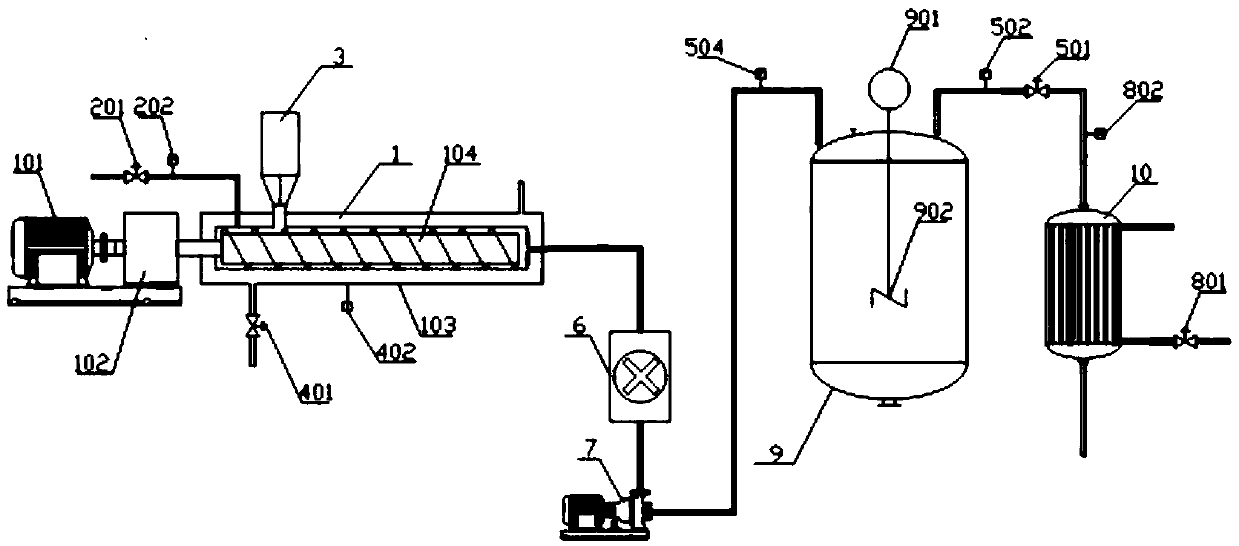

[0031] Example 1: To produce a non-water-mixed release agent, first set the dosage of each material according to the formula, and set the temperature at 80°C; first open the heat transfer oil regulating valve 401, and the heat transfer oil enters to preheat the screw 104; then open the silicone oil adjustment Valve 201, feeder 3, raw liquid flow meter 504, steam regulating valve 801, pure water valve 501, the raw material is added to the reactor 1, the motor 101 is turned on to drive the rotation of the screw 104 through the gear box 102, and the raw material starts to react under stirring, With heating, the reaction can be carried out quickly, and the reaction rate can reach 90% in a short time; there will be agglomeration between the materials, and the materials will be transported from the reactor 1 to the colloid mill 6, and the agglomerated materials will be ground to increase the specific surface area of the materials; The material is pumped into the mixing tank 9 by the ...

Embodiment 2

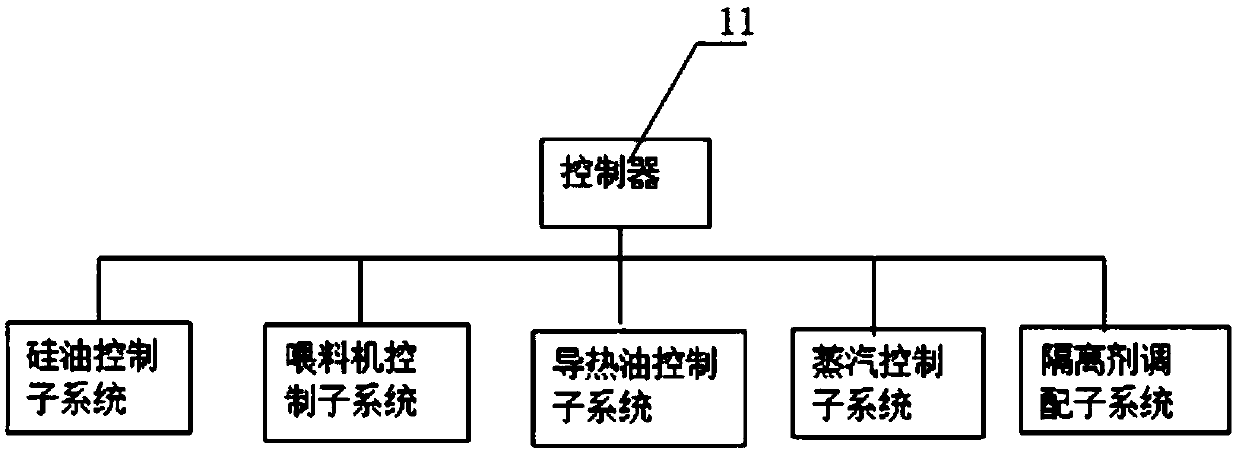

[0032] Embodiment 2: produce W-1620D4\D5 (2 times watering type) release agent, production capacity is identical, on the basis of embodiment 1, controller 11 controls silicone oil regulating valve 201 according to silicone oil consumption and silicone oil flowmeter 202 feedback values Carry out PID control, appropriately reduce the opening degree of the silicone oil regulating valve 201; the controller 11 performs proportional control on the feeder 3 according to the batching ratio set by the process and the actual flow rate measured by the silicone oil flowmeter 202, and the output signal of the control controls the feeder 3. The feeding amount of the feeder 3; the controller 11 performs PID control on the heat transfer oil regulating valve 401 according to the reactor temperature 80°C set by the process and the feedback value of the reactor thermometer 402, and the output signal of the PID control controls the heat transfer oil regulating valve 401. The size of the opening, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com