Multi-station automatic detection system for bending slope of stamped steel plate

A punched steel plate, automatic detection technology, applied in the field of digital measurement, can solve the problems of increased workload, low accuracy, low efficiency, etc., to achieve the effect of easy adjustment and reasonable device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

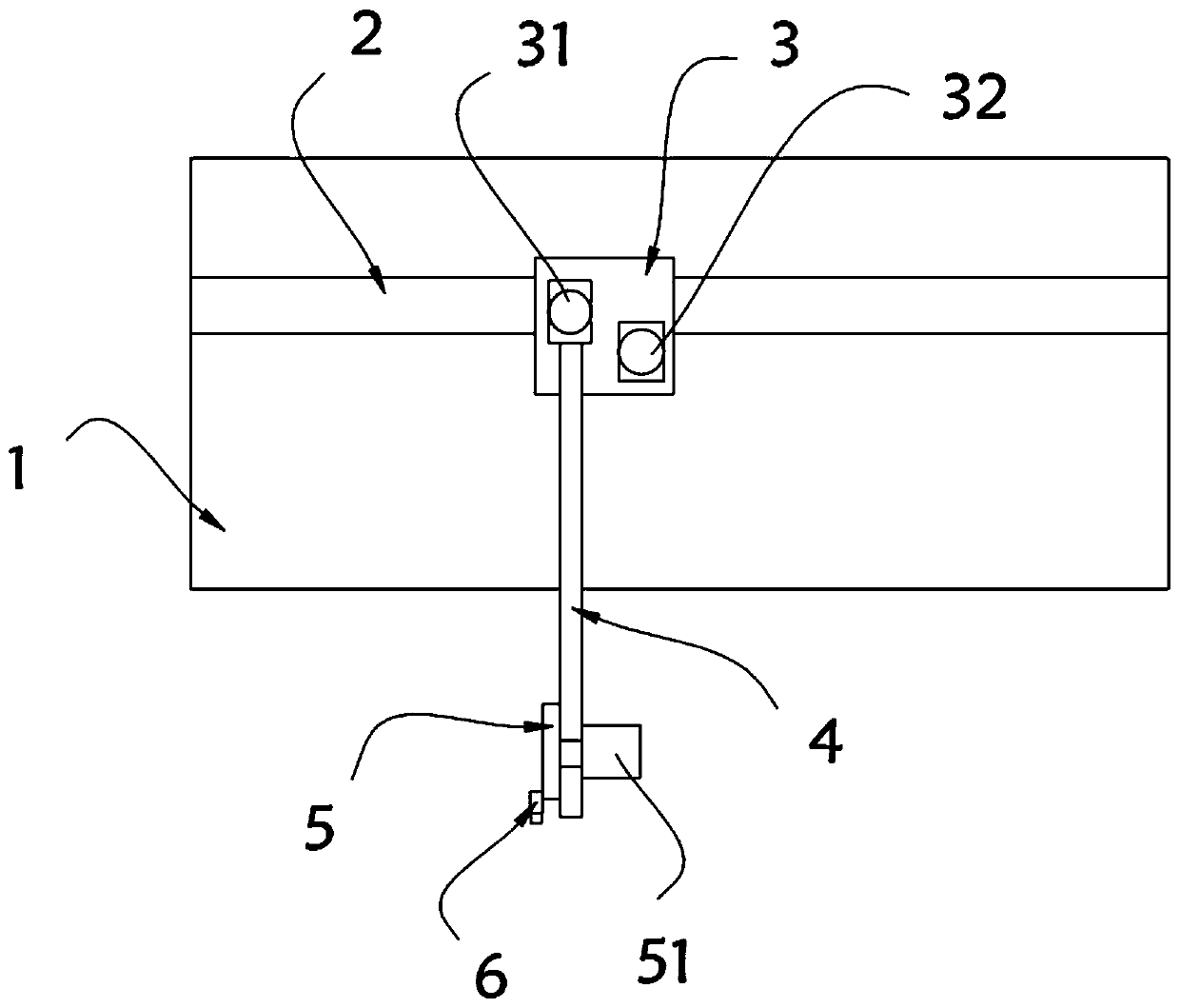

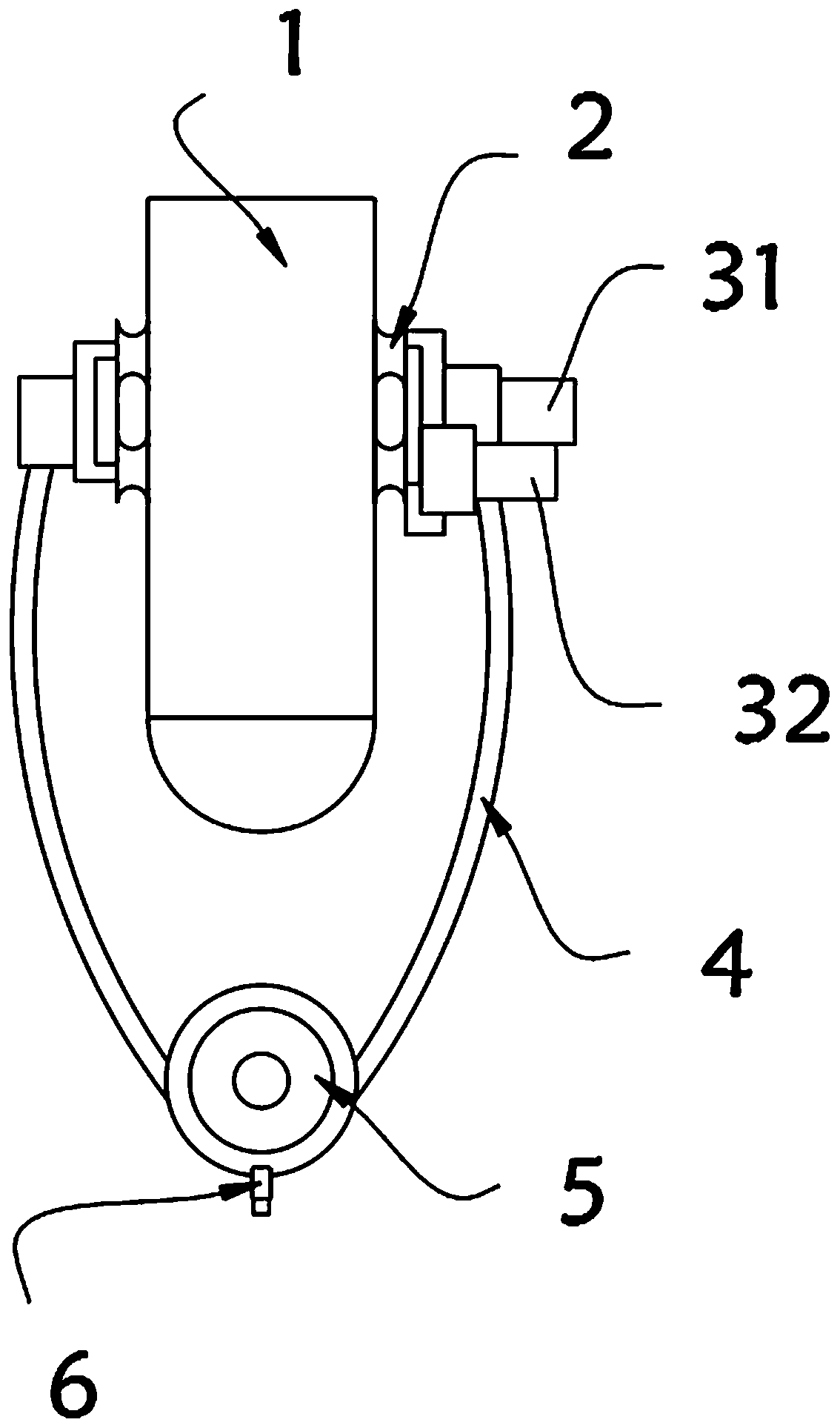

[0049] Multi-station automatic detection system for bending slope of stamped steel plate, such as figure 1 and figure 2As shown, it includes a detection tool installed on the stamping body 1 and a detection system for detection data analysis. The detection tool includes slide rails 2 installed on both sides of the outer wall of the stamping body 1, and the outer surface of each slide rail 2 is There are receiving slides 3, and a suspension support frame 4 is installed between the two receiving slides 3. The bottom of the suspension support frame 4 is equipped with an indexing dial 5, and the bottom end of the indexing dial 5 is installed with a laser distance measuring device. Head 6, the outer wall of the receiving slide seat 3 is provided with a connecting shaft 34 near the side of the supporting frame servo motor 31, the suspension supporting frame 4 is installed on the connecting shaft 34, and the output shaft of the supporting frame servo motor 31 is coaxially arranged w...

Embodiment 2

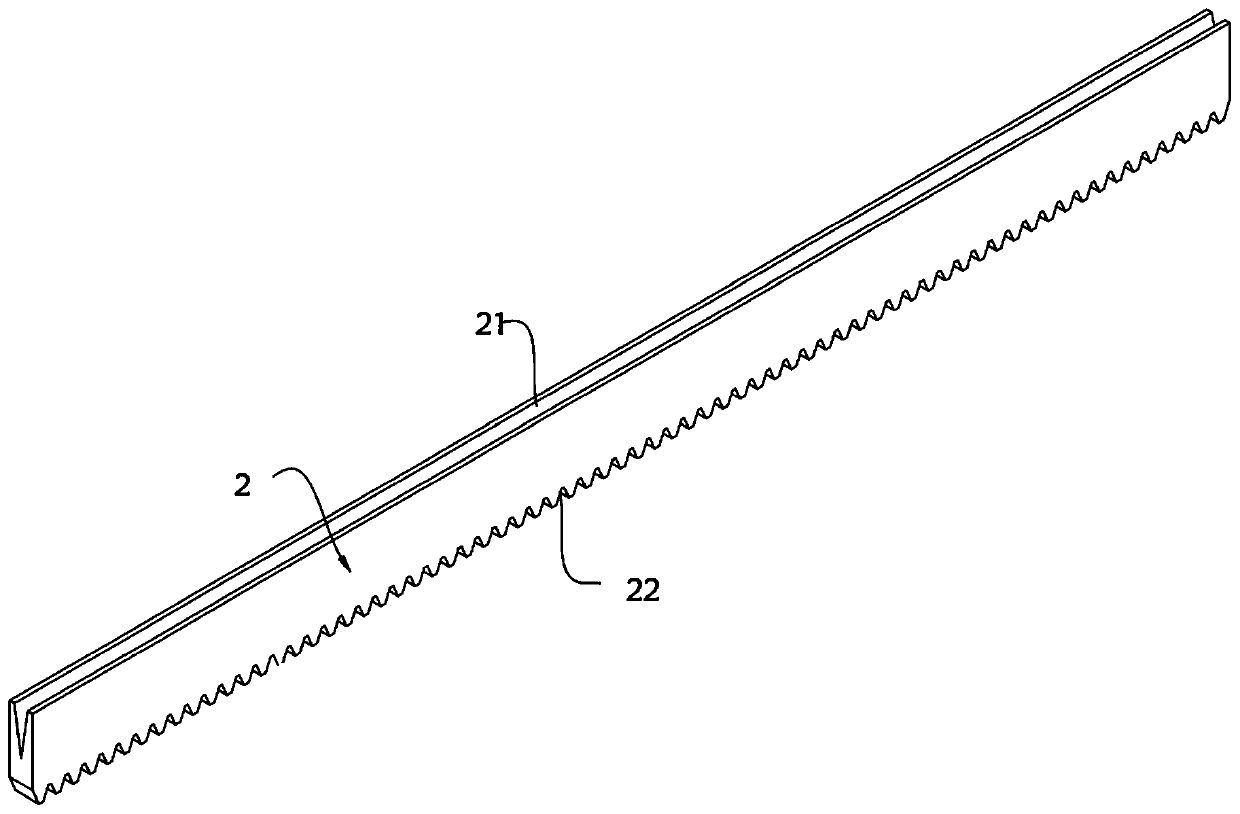

[0055] As the second embodiment of the present invention, in order to facilitate the adjustment of the measurement position, the inventors are provided with a slide rail 2, and make improvements to the slide rail 2, as a preferred embodiment, such as image 3 and Figure 4 As shown, a V-shaped slideway 21 is provided on the top of the slide rail 2, a rack 22 is installed on the bottom of the slide rail 2, and a support frame servo motor 31 and a pinion servo motor 32 are respectively installed on the outer surface of the receiving slide seat 3. The top of the inner wall of the slide seat 3 is provided with a block 33, and the inner wall of the receiving slide seat 3 is provided with a pinion 35, and the outer wall of the pinion 35 is provided with a connecting cylinder 36, the pinion 35 meshes with the rack 22, and the output of the pinion servo motor 32 The shaft and the connecting cylinder 36 are arranged coaxially.

[0056] In this embodiment, the clamping block 33 is in t...

Embodiment 3

[0061] As a third embodiment of the present invention, in order to facilitate the adjustment of the angle of measurement, the inventors made improvements to the graduation dial 5, as a preferred embodiment, such as figure 1 and figure 2 As shown, one end of the indexing dial 5 is equipped with an indexing dial stepper motor 51, the indexing dial 5 and the suspension support frame 4 are rotationally connected, and the output shaft of the indexing dial stepping motor 51 and the indexing dial 5 welding fixed.

[0062] In this embodiment, the index dial 5 is installed on the suspension support frame 4 through a bearing ring, so that the index dial 5 can rotate on the suspension support frame 4 conveniently.

[0063] Further, the indexing dial 5 and the laser distance measuring head 6 are welded and fixed, so that the laser distance measuring head 6 is fixed on the indexing dial 5, and the laser distance measuring head is adjusted by the rotation of the indexing dial 5 6 measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com