Steel bar bending device for circumferential fastening of crystallization tank

A technology of bending device and crystallizing tank is applied in the field of steel bar bending device for circumferential fastening of crystallizing tank. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

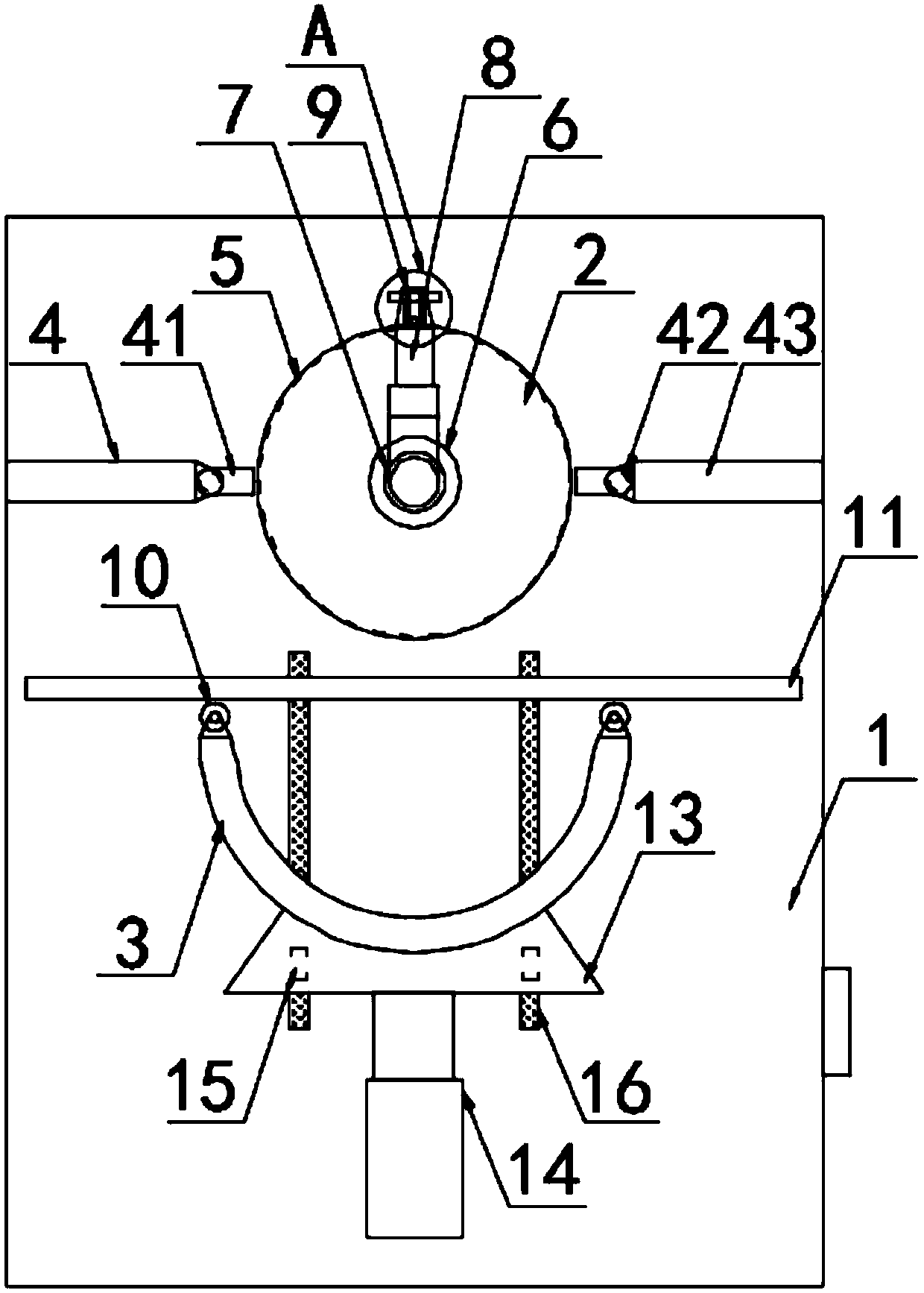

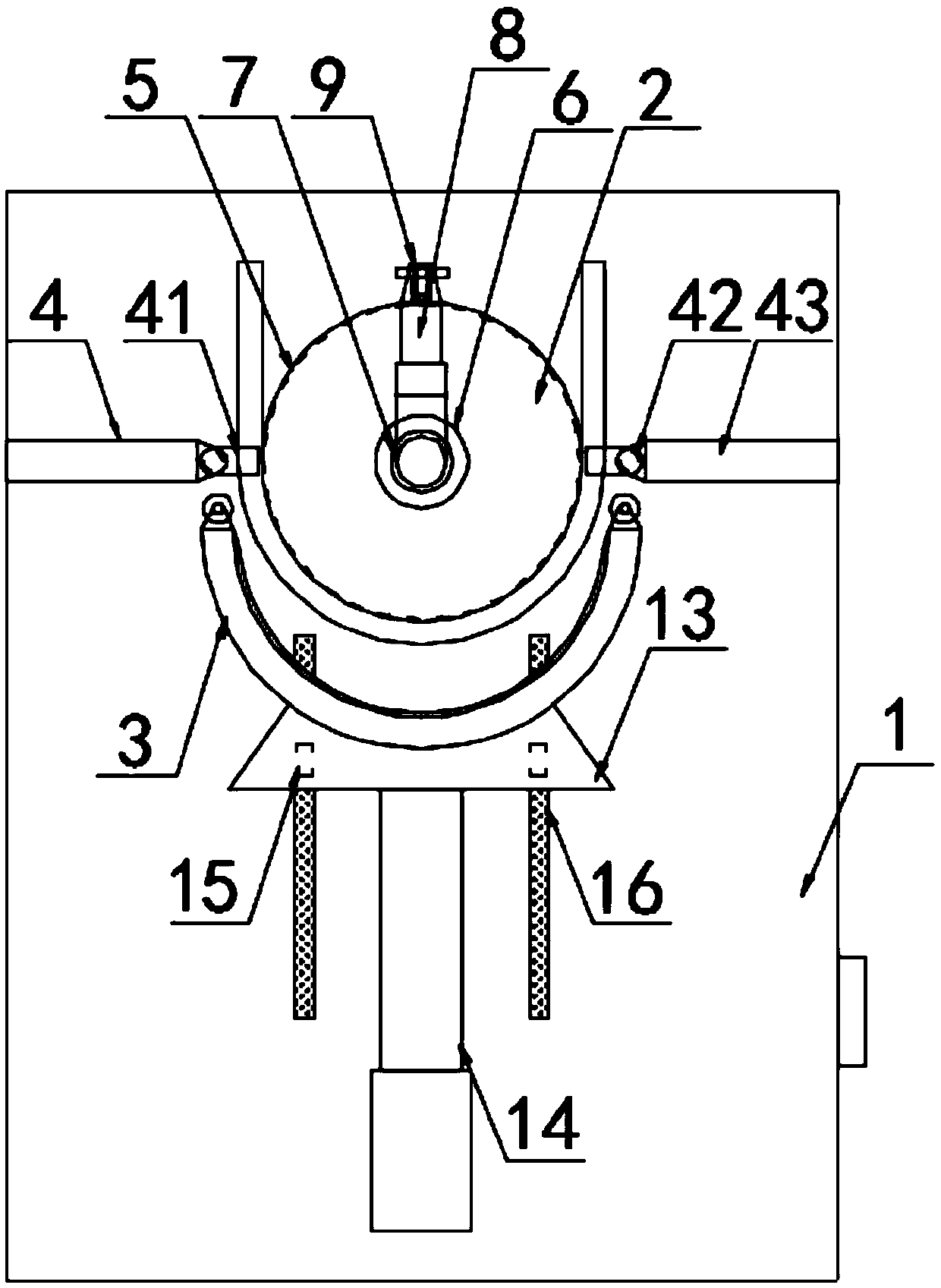

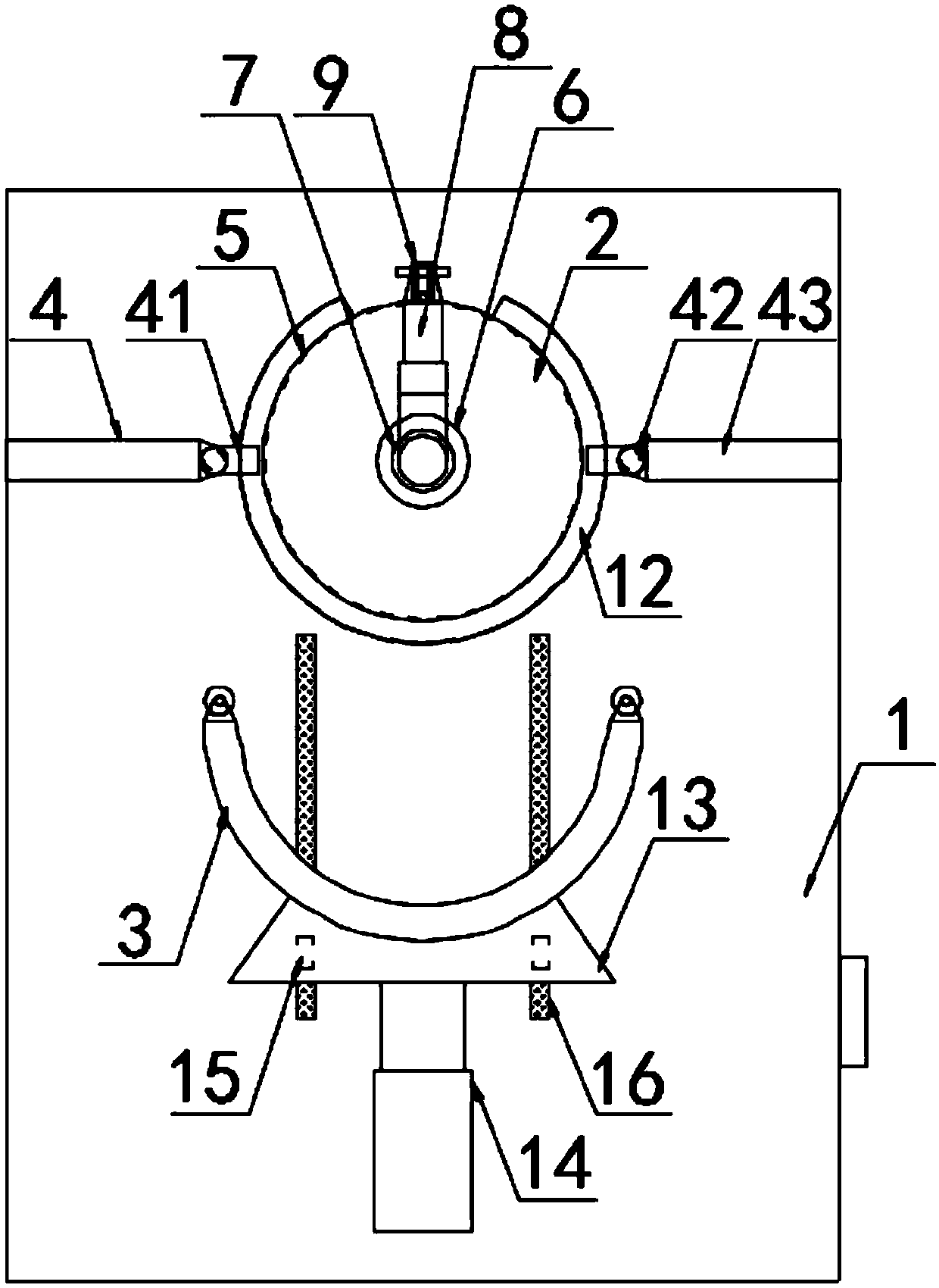

[0027] according to Figure 1-4 A steel bar bending device for circumferential fastening of a crystallization tank shown includes a workbench 1, an inner formwork 2, an outer formwork 3 and a pressing plate mechanism 4 are arranged on the top of the workbench 1, and the outer formwork 3 is arranged in the inner On the front side of the template 2, the platen mechanism 4 is arranged on both sides of the inner template 2, an annular groove 5 is provided on the outer wall of the inner template 2, and a positive and negative motor 6 is embedded on the inner template 2, and the positive and negative motor 6 is embedded on the inner template 2. The top of the motor 6 is connected with a first elevating mechanism 7 through a rotating shaft, and the top end of the first elevating mechanism 7 is fixedly connected to the first telescopic mechanism 8 through a bracket, and the first telescopic mechanism 8 is arranged perpendicular to the first elevating mechanism 7. A rolling pressing me...

Embodiment 2

[0032] according to Figure 1-3 A steel bar bending device for the circumferential fastening of the crystallization tank is shown. The rear side of the outer template 3 is fixed with a fixed plate 13, and the rear side of the fixed plate 13 is fixed with a second telescopic mechanism 14. The two telescopic mechanisms 14 are fixedly connected with the workbench 1, the bottom sides of the fixed plate 13 are provided with slide feet 15, and the workbench 1 corresponding to the slide feet 15 is provided with a guide rail 16, and the slide feet 15 and the guide rail 16 slide The connection is convenient for limiting the outer formwork 3 so that it can move stably and parallel without inclination affecting processing;

[0033] The first lifting mechanism 7, the second lifting mechanism 42, the first telescopic mechanism 8 and the second telescopic mechanism 14 are specifically electric telescopic rods, and a PLC controller is provided on one side of the workbench 1;

[0034] accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com