Electric spark machining method of outer circle surface array special-shaped grooves

A technology of outer circular surface and processing method, which is applied in the field of mechanical processing, can solve the problems of high processing difficulty, difficulty in accurately copying sharp or concave corners of the workpiece, poor processing consistency, etc., and achieve the effect of reducing repeated positioning errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0018] Taking the machining of the special-shaped groove of the aero-engine plunger as an example, it will be described in detail.

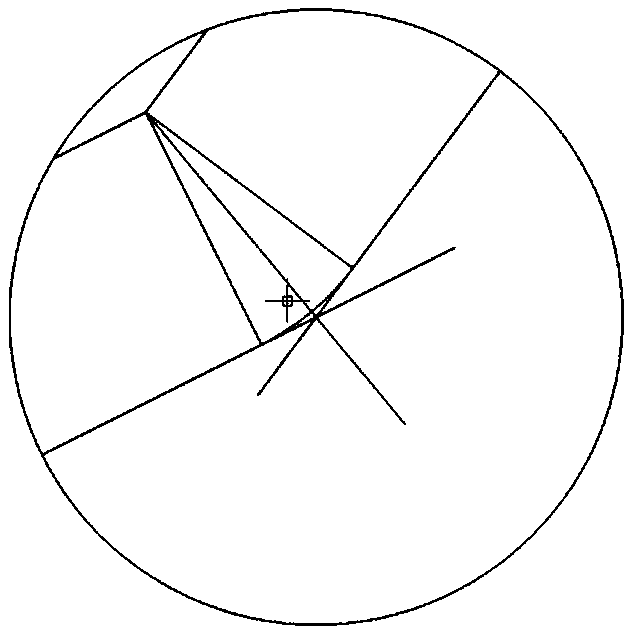

[0019] According to the requirements of the parts to be processed, the circumference length is firstly indexed. The plunger is a shaft sleeve part, and four special-shaped grooves are evenly distributed on the cylindrical surface. The indexing plate rotates 90° each time to process the next special-shaped groove;

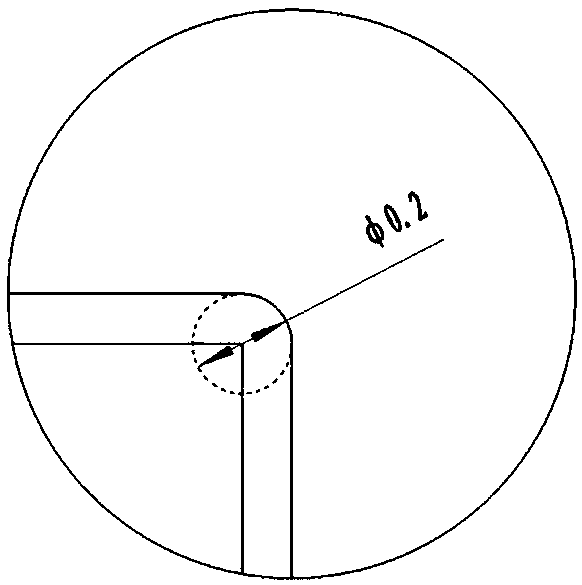

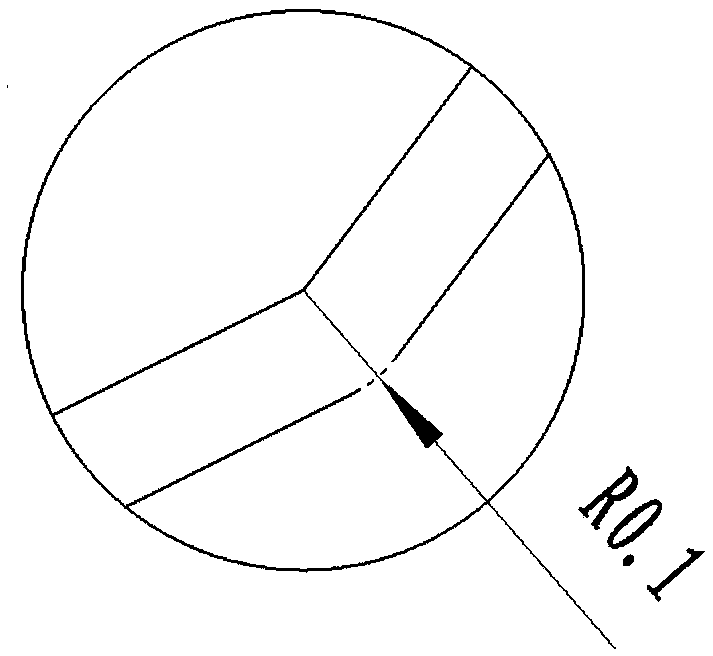

[0020] Make special-shaped electrodes according to the size and shape requirements of special-shaped grooves. Considering that EDM cannot process sharp corners and concave corners, the shape of the special-shaped electrode is not completely consistent with the shape of the machined special-shaped groove.

[0021] EDM cannot process sharp corners during the machining process, so it can only infinite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com