Method for improving yield rate of aviation blade machining

An aviation blade and yield technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reduced processing efficiency, poor blade accuracy, blade processing deformation, etc., to prevent processing deformation and improve processing efficiency. , the effect of large cutting depth of the tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

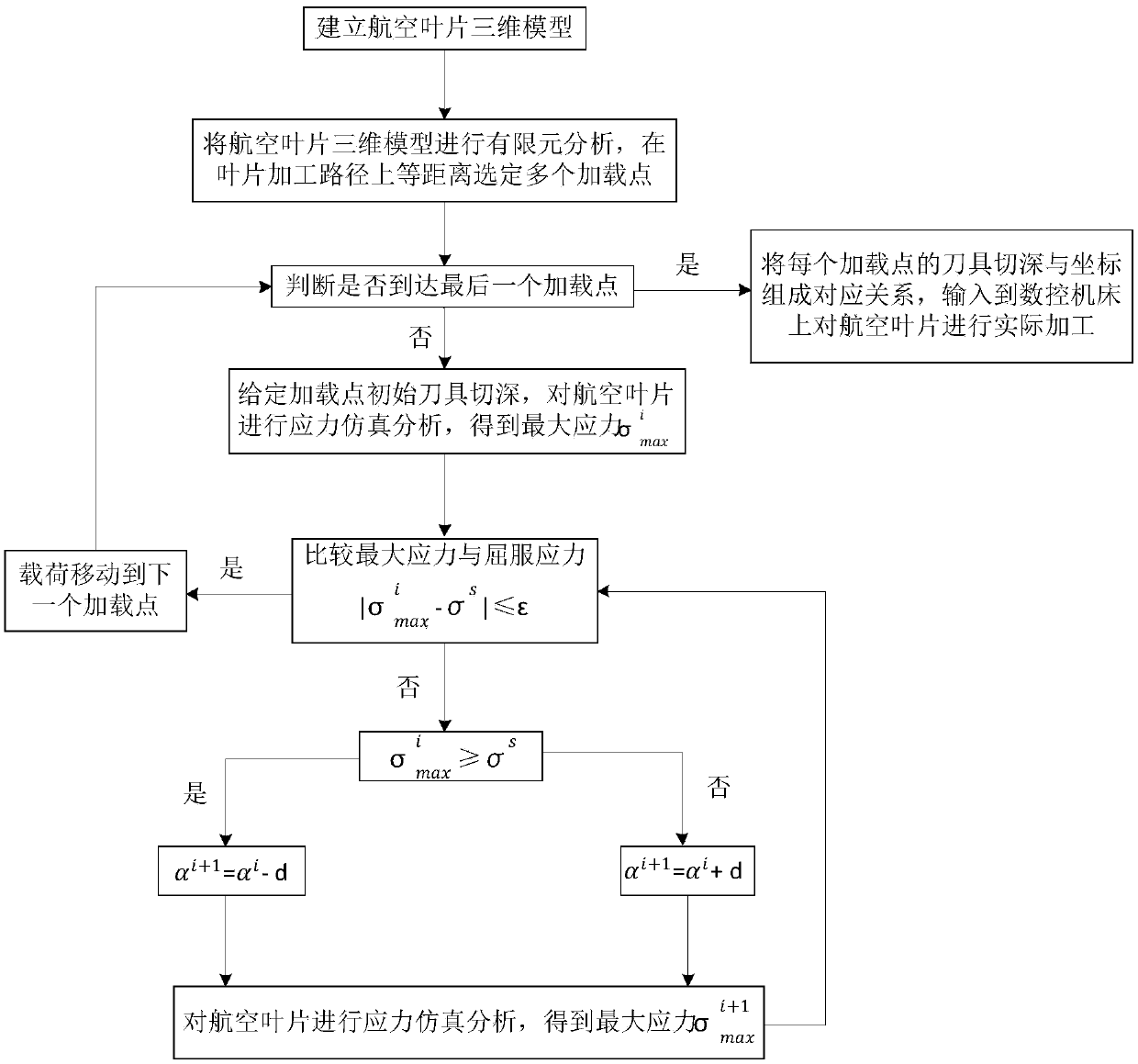

[0030] A method for improving the yield rate of aerospace blades, such as figure 1 shown, including the following steps:

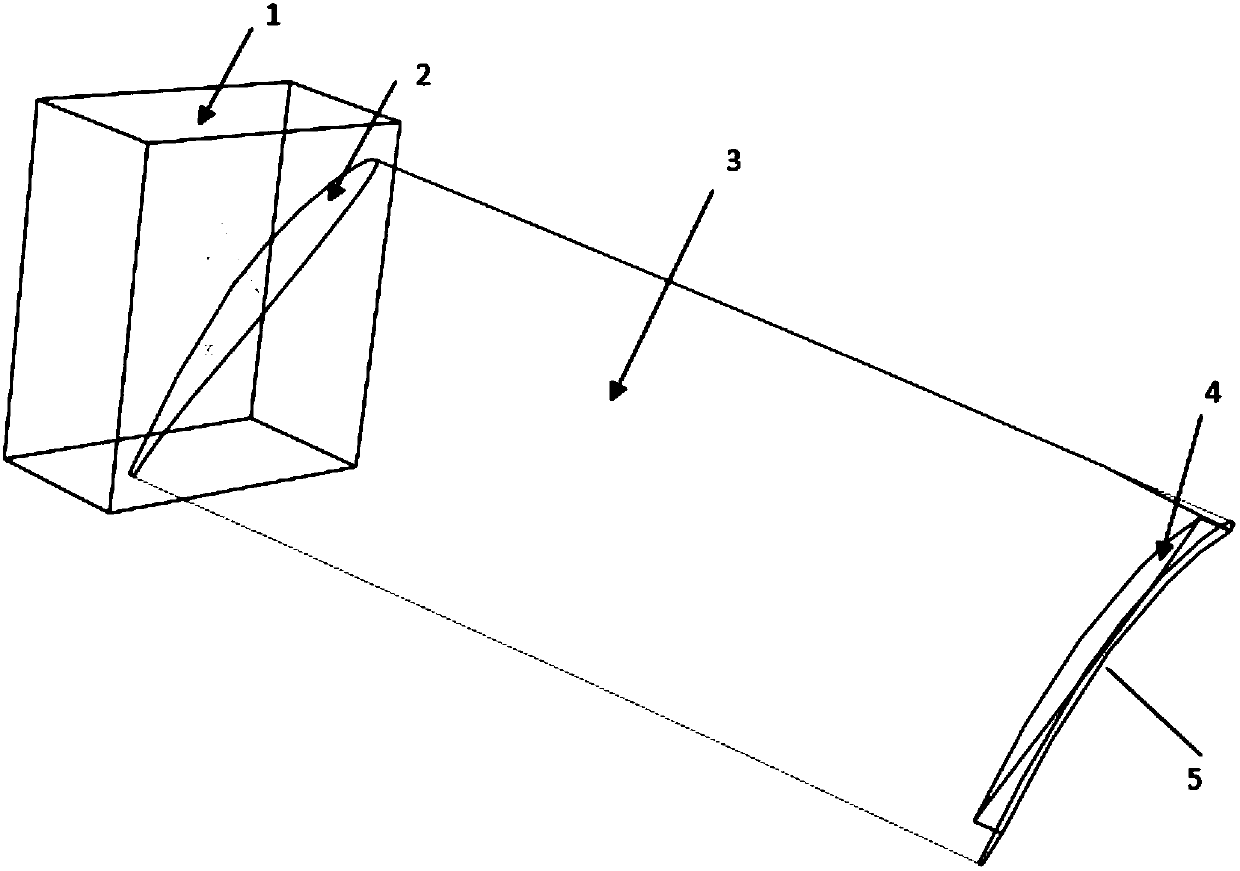

[0031] Step 1. Establish a three-dimensional model of the aviation blade, such as figure 2 As shown, this aviation blade includes the blade tenon 1 and the blade root 2 at the end, the blade tip 4 at the front end, and the blade back 3 and the blade pot 5 connecting the blade root 2 and the blade tip 4; this blade is an aviation thin-walled blade, and is The first stage stator blade of an aero-engine, the size is 125mm*40mm*6mm.

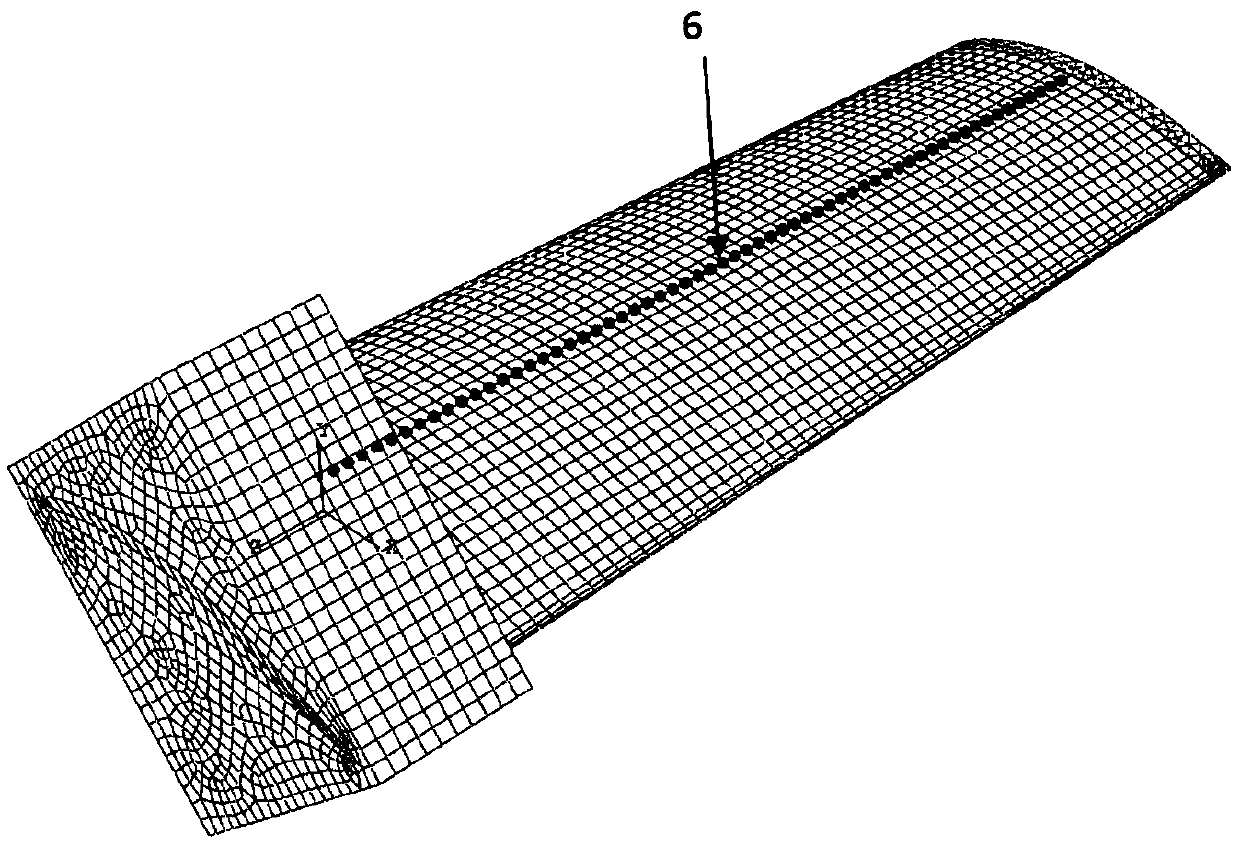

[0032] Step 2. Import the blade model into the finite element analysis software Abaqus, draw up a machining path that is spirally distributed along the length direction of the blade back 3 and the blade pot 5, and select multiple loading points equidistantly on the blade machining path as cutting points during stress analysis. point of application of force.

[0033] Step 3. Convert the depth of cut of the tool at the first lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com