Self-cleaning high-speed and high-efficiency inkjet piezoelectric spray head

An inkjet, self-cleaning technology, applied in printing and other directions, can solve problems such as waste of ink, disconnection faults, and increased costs, and achieve the effects of improving printing accuracy, saving maintenance costs, and reducing failure rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

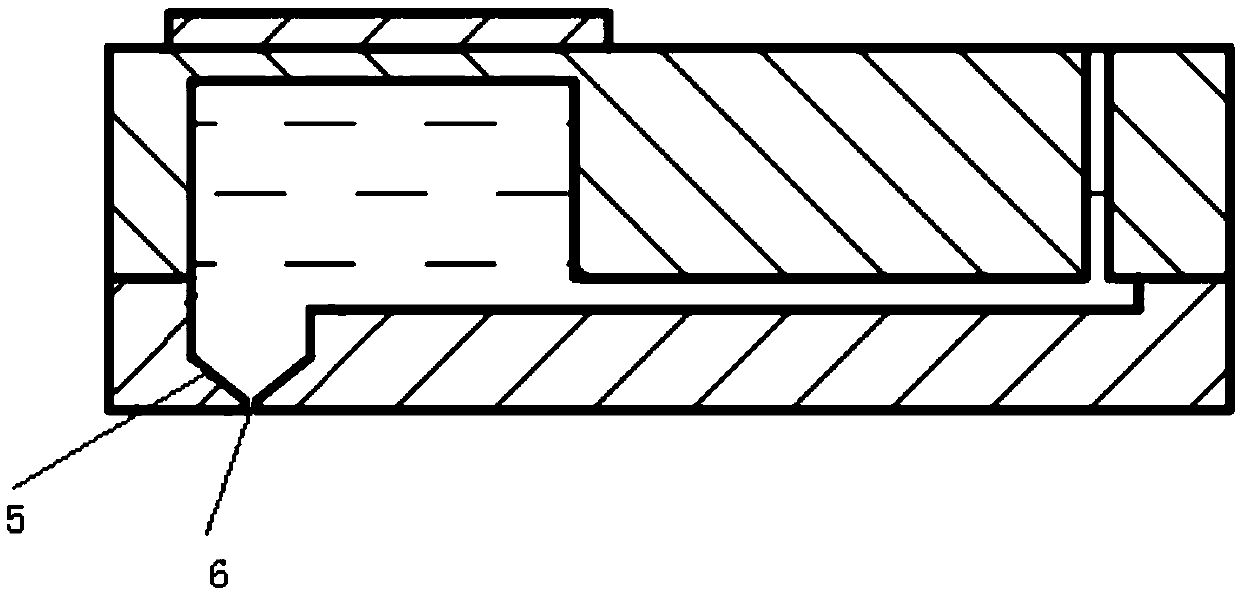

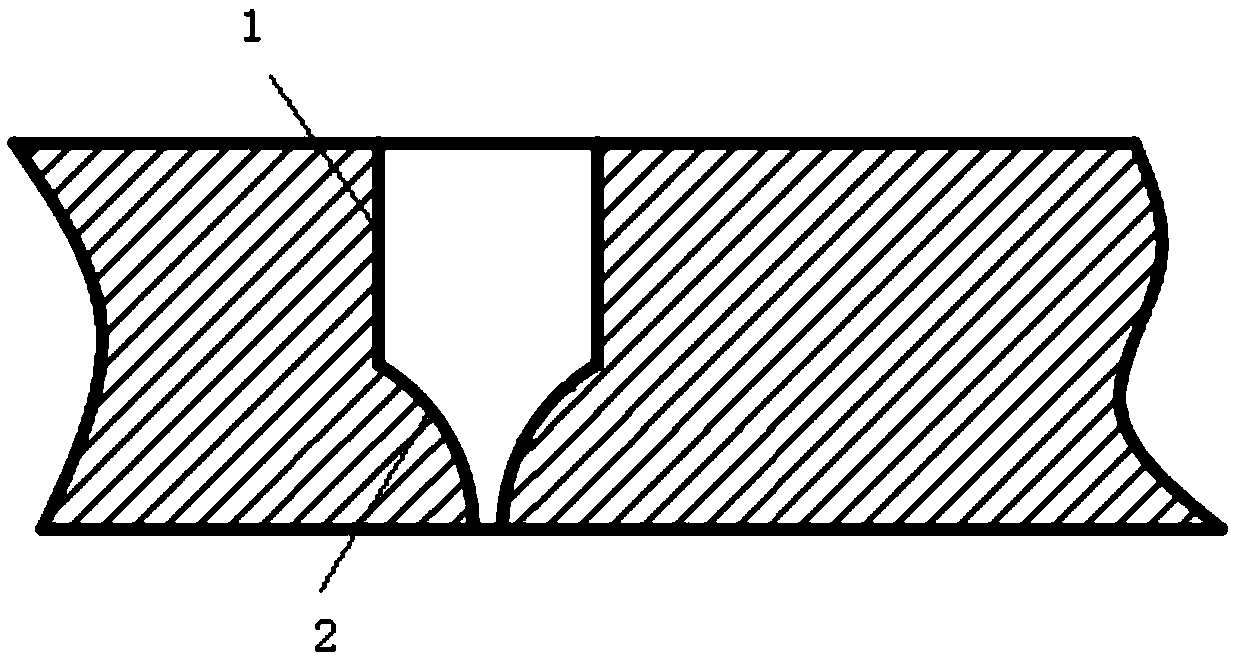

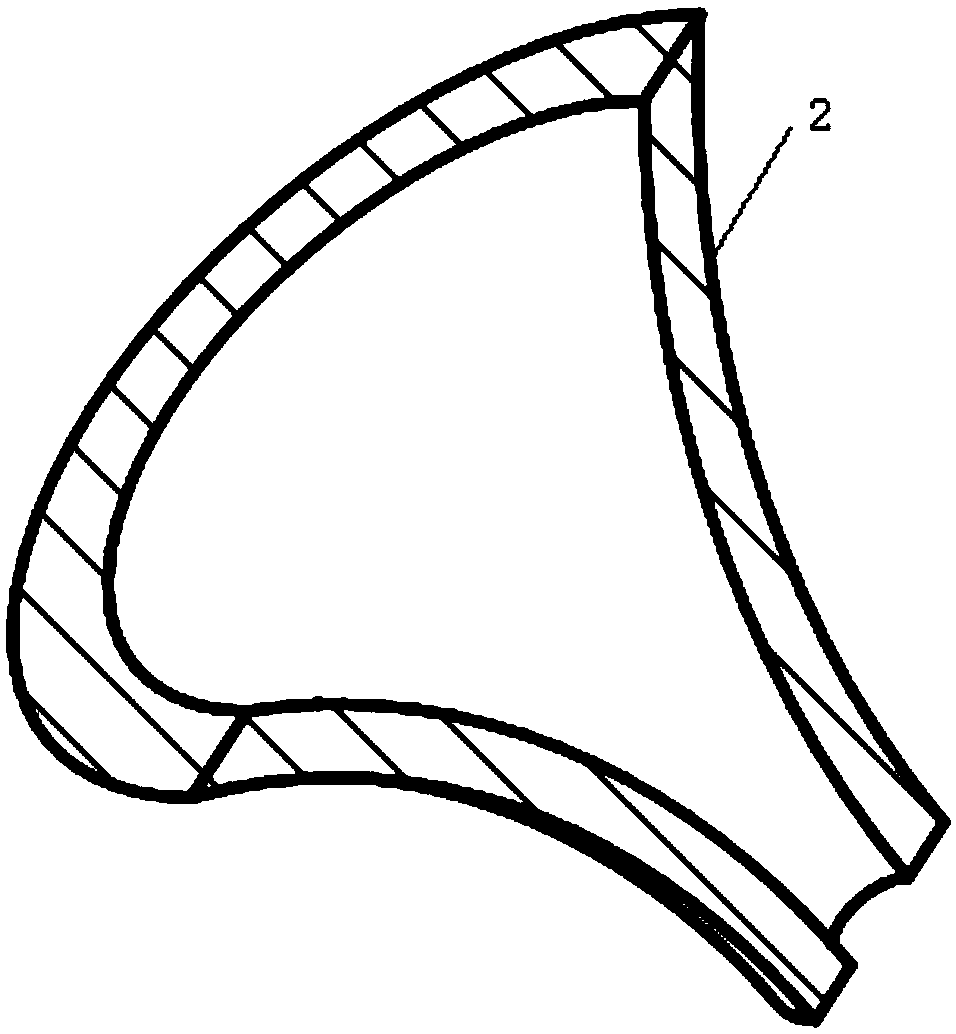

[0034] A self-cleaning high-speed and high-efficiency inkjet piezoelectric nozzle, such as figure 2 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 , including a nozzle, the nozzle is provided with an inkjet channel, the inkjet channel includes a communication section 1 and a nozzle section 2, the ink outlet of the communication section 1 is connected to the ink inlet of the nozzle section 2, and the inner wall of the nozzle section 2 is provided with a multi-level gradient The micro-nano structure, the multi-level gradient micro-nano structure includes a micro-scale structure and a nano-scale structure, the micro-scale structure is arranged on the inner wall surface of the nozzle section 2, and the nano-scale structure is arranged on the micro-scale structure.

[0035] In the self-cleaning high-speed and high-efficiency inkjet piezoelectric nozzle, the inner wall surface of the inkjet channel of the nozzle has a multi-level gradient micro-nano structure. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com