Vacuum valve for aluminum alloy high-pressure die casting based on additive manufacturing technology

A technology of additive manufacturing and aluminum alloy, which is applied in the field of vacuum valves for aluminum alloy high-pressure die-casting, can solve the problems of reducing production efficiency, increasing production costs, and small conductance, achieving stability and efficiency improvement, and convenient maintenance. Reduced closing stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

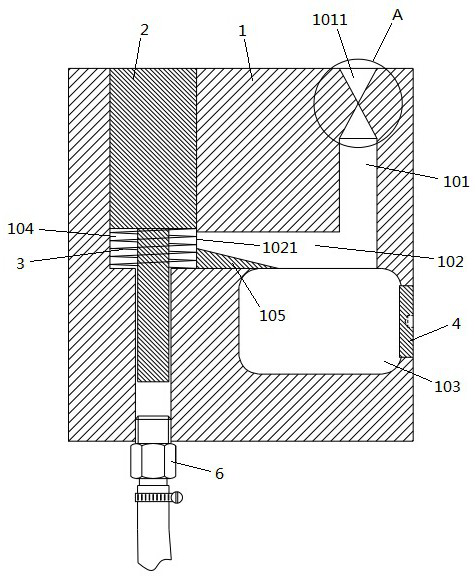

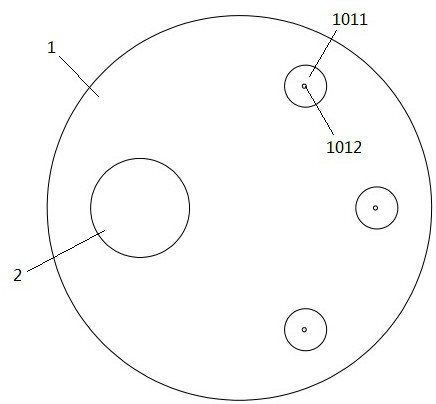

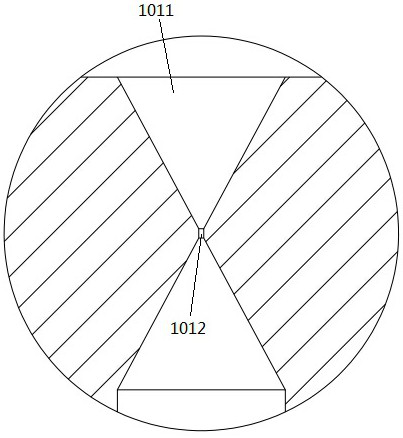

[0030] Embodiment 1: as Figure 1~3 As shown, an aluminum alloy high-pressure die-casting vacuum valve based on additive manufacturing technology includes a valve body 1, a valve core 2 and an elastic member 3; the valve body 1 is processed by additive manufacturing technology, and the valve body 1 is increased by The raw material for manufacturing the material is S136 die steel, H13 die steel or other additive manufacturing die steel powders of the same level with a particle size of 15-30 μm. The overall structure is cylindrical, and the valve body 1 is provided with valve holes 104, multiple Vacuum air channel A101, vacuum air channel B102; the air inlet 1011 of the vacuum air channel A101 is located on the end face of the valve body 1, and the air inlet 1011 is an axisymmetric double-cone structure, and the junction of the double-cone structure It is an air inlet 1012; the vacuum air passage B102 is located in the valve body 1, one end of the vacuum air passage B102 is conn...

Embodiment 2

[0031] Embodiment 2: This embodiment is a further improvement of Embodiment 1. The main improvement is that when Embodiment 1 is in use, a small amount of molten metal slag and impurities will enter the vacuum air passage, which will block the air passage and damage the vacuum system; And in the present embodiment, can avoid above-mentioned defect, specifically:

[0032] The valve body 1 is provided with a dust collection chamber 103 inside, and the dust collection chamber 103 is located at the junction of the vacuum air passage A101 and the vacuum air passage B102; the side wall of the valve body 1 is provided with a maintenance port through the dust collection chamber 103, And the maintenance port is threaded with a plug 4 ; the plug 4 does not protrude from the side wall of the valve body 1 . The valve body 1 of this embodiment is provided with a dust collection chamber 103, and a maintenance port is provided on the dust collection chamber 103, which can collect molten meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com