Method for installing liquid cargo pump base of duplex stainless steel chemical tank

A technology of duplex stainless steel and chemical tankers, which is applied to ship components, ship design, ship construction, etc., can solve the problems of difficult positioning, welding and fixing of liquid cargo pump bases, etc., to improve construction accuracy, ensure accuracy, and improve The effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

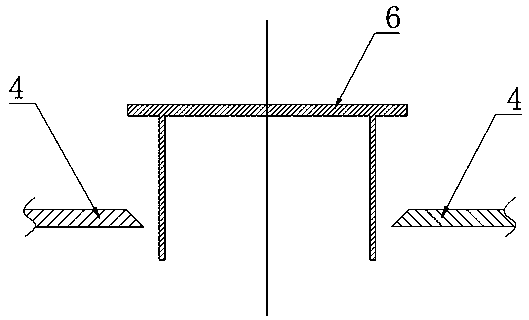

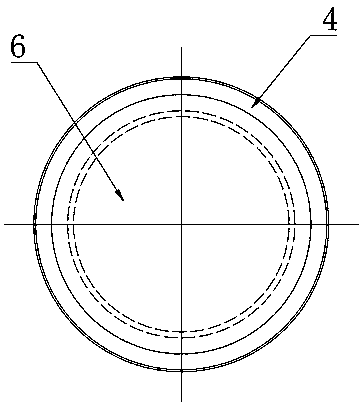

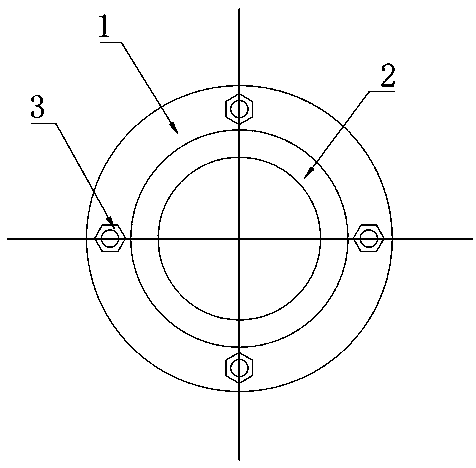

[0033] Example: such as Figure 1 to Figure 9 As shown, a method for installing the base of a duplex stainless steel chemical tanker liquid cargo pump includes the following steps:

[0034]Step 1. Make a deck hole positioning mechanism, the deck hole positioning mechanism includes a first hole template 1 and a second hole template 2, and the first hole template 1 and the second hole template 2 are both thick It is a circular plate-shaped structure of 6 mm, the inner diameter of the first hole-opening template 1 is 448 mm, the inner diameter of the second hole-opening template 2 is 408 mm, and the first hole-opening template 1 is provided with Four first bolt holes, the second hole template 2 is provided with four second bolt holes, the four first bolt holes correspond to the four second bolt holes respectively, the first hole The template 1 is arranged above the second hole template 2, and the center line of the first hole template 1 coincides with the center line of the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com