Reciprocating-type feeding mechanism

A feeding mechanism, reciprocating technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing equipment purchase and use costs, low reciprocation time accuracy, and confusion in production lines, and achieve equipment purchases. Low cost, low maintenance and use costs, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

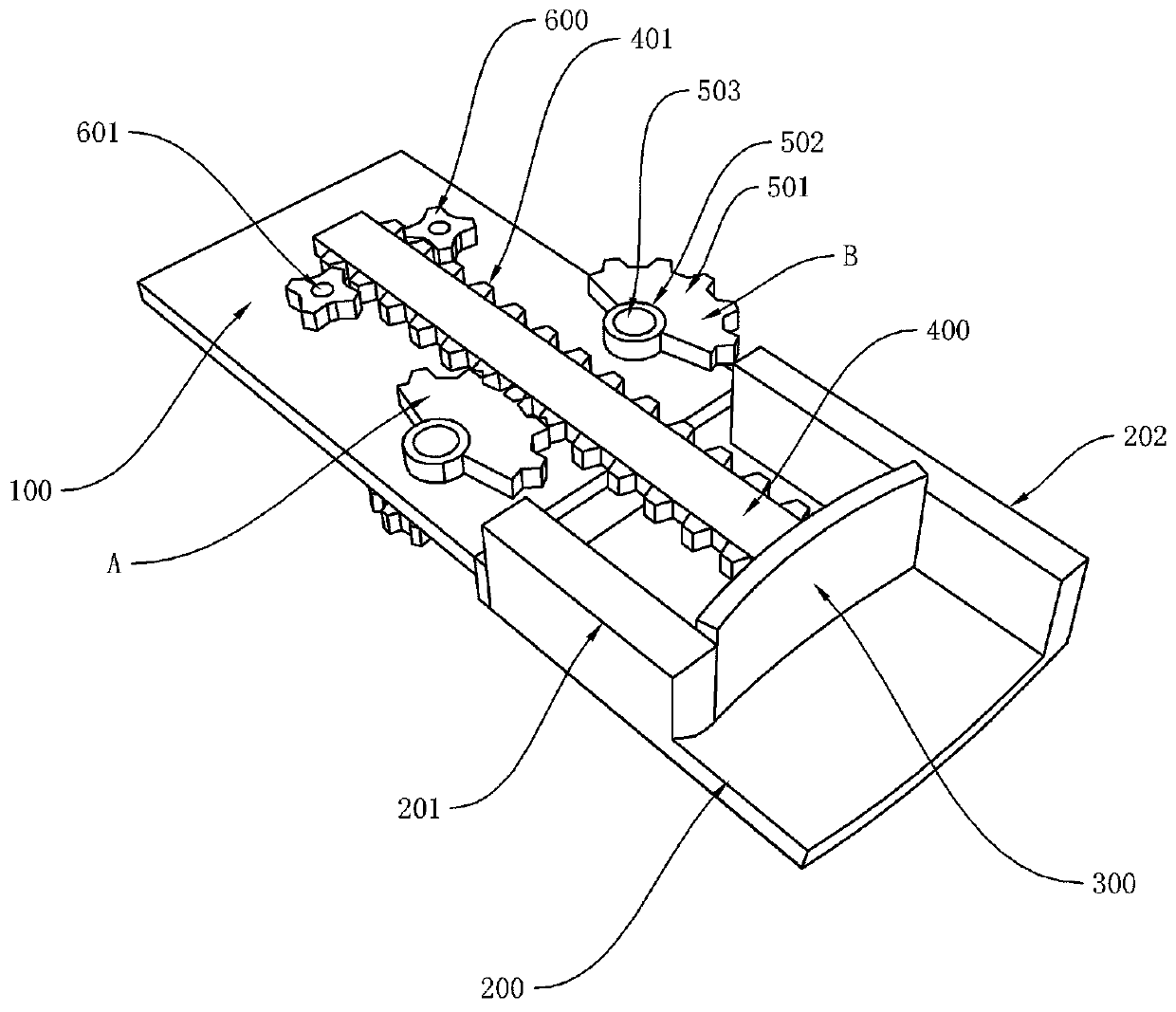

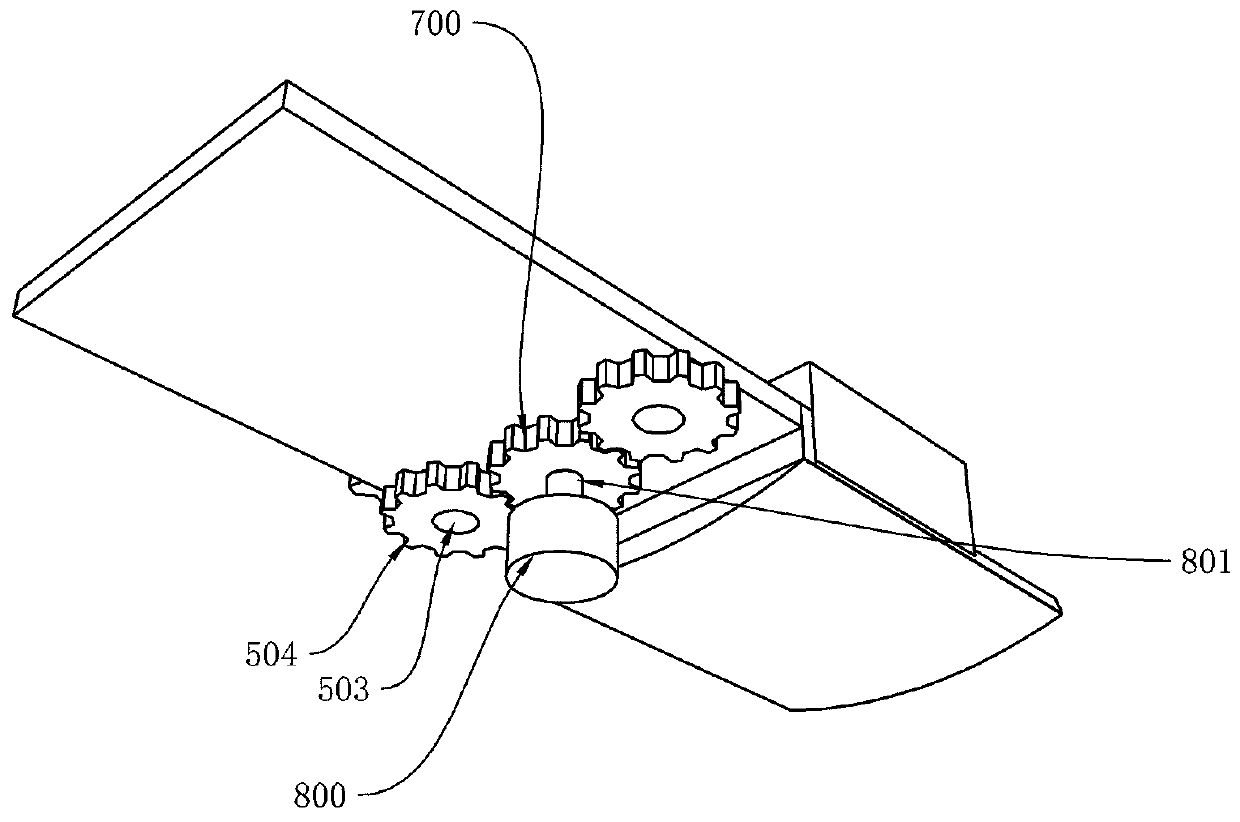

[0024] see Figure 1 to Figure 2 , a reciprocating feeding mechanism, including a partition 100, a material supporting plate 200, a pushing plate 300, a forward half-tooth assembly A, and a rear half-tooth assembly B, and the pushing plate 300 and the pushing rack One end of 400 is connected and fixed, and both sides of the pushing rack 400 are provided with engaging teeth 401;

[0025] The pusher rack 400 is assembled by meshing with the half gear 501 of the forward half gear assembly A through the engaging teeth 401 on one side to form a gear transmission structure;

[0026] The forward pushing half gear assembly A also includes a connecting ring 502 and a connecting shaft 503, the connecting ring 502 is fixed on the half gear 501 and assembled and fixed with one end of the connecting shaft 503;

[0027] The other end of the connecting shaft 503 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com