Glass substrate full-automatic cutting device and method

A glass substrate and cutting equipment technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of reduced work efficiency, poor cutting effect, incomplete removal of cutting platform debris, etc., to prevent static electricity, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

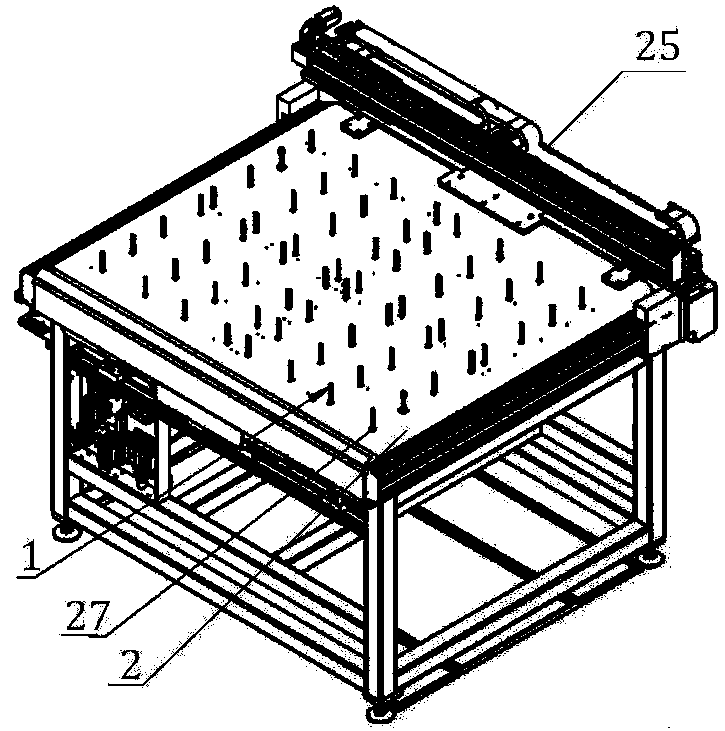

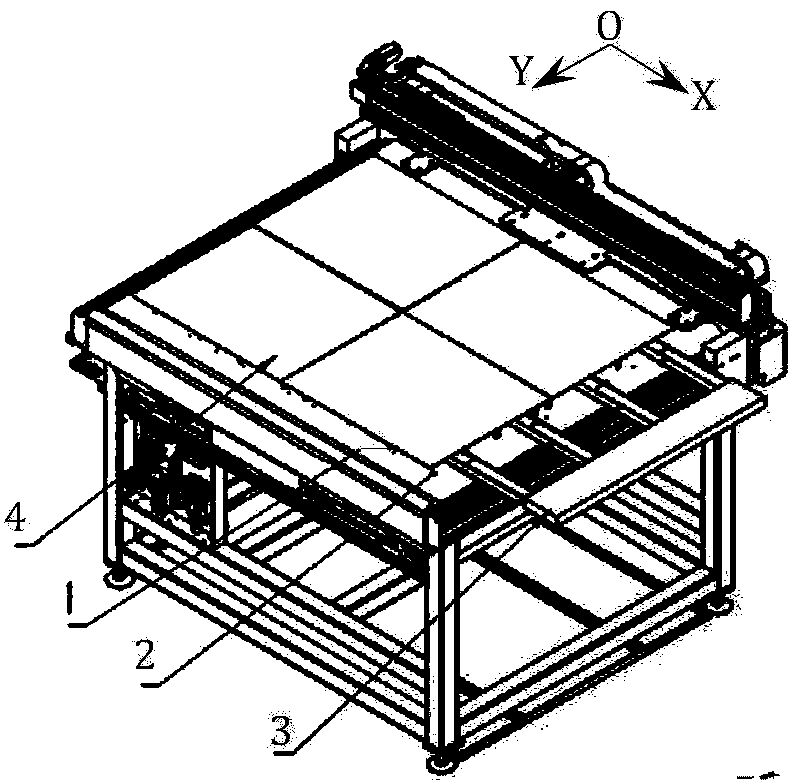

[0148] Using the glass substrate automatic cutting equipment shown in Figure 1-9, the glass substrate 4 to be cut is a scrapped rectangular glass substrate.

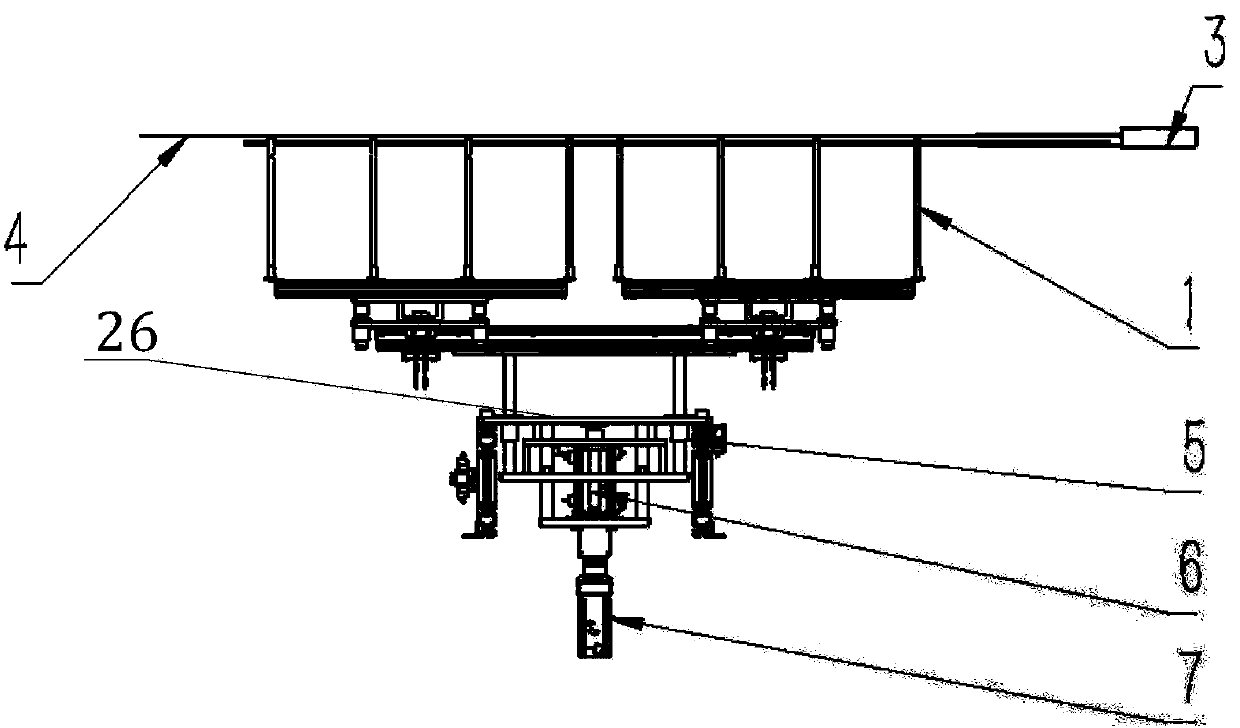

[0149] The cutting platform 2 is a rectangular marble platform. The size of the cutting platform 2 is slightly larger than that of the glass substrate 4 to be cut. The cutting track is cross-shaped. According to the cutting track, the cutting platform 2 is divided into four equal parts ABCD. The pin holes 27 are on the cutting platform 2. Distributed in a row parallel to one side of the marble platform, the pin holes 27 on each adjacent two areas are distributed symmetrically with respect to the cutting track in the middle of these two areas, the pins 1 of the lifting device 34 and the pins on the cutting platform 2 The foot holes 27 are arranged correspondingly, so that when the glass substrate 4 falls on the rising pin 1 , the force is uniformly applied everywhere. The adsorption holes 28 are arranged avoiding the pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com