Turnout laying replacement vehicle and railway turnout laying replacement system

A technology for turnouts and tracks, which is applied to the field of turnout changeover and railway turnout changeover systems, can solve problems such as the separation of sleepers and traveling wheels, hidden dangers of equipment safety, etc., so as to reduce the center of gravity, avoid safety accidents, and satisfy the effect of stable support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the purpose, technical features and technical effects of the technical solution of the present invention more clear, the exemplary solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of specific embodiments of the present invention.

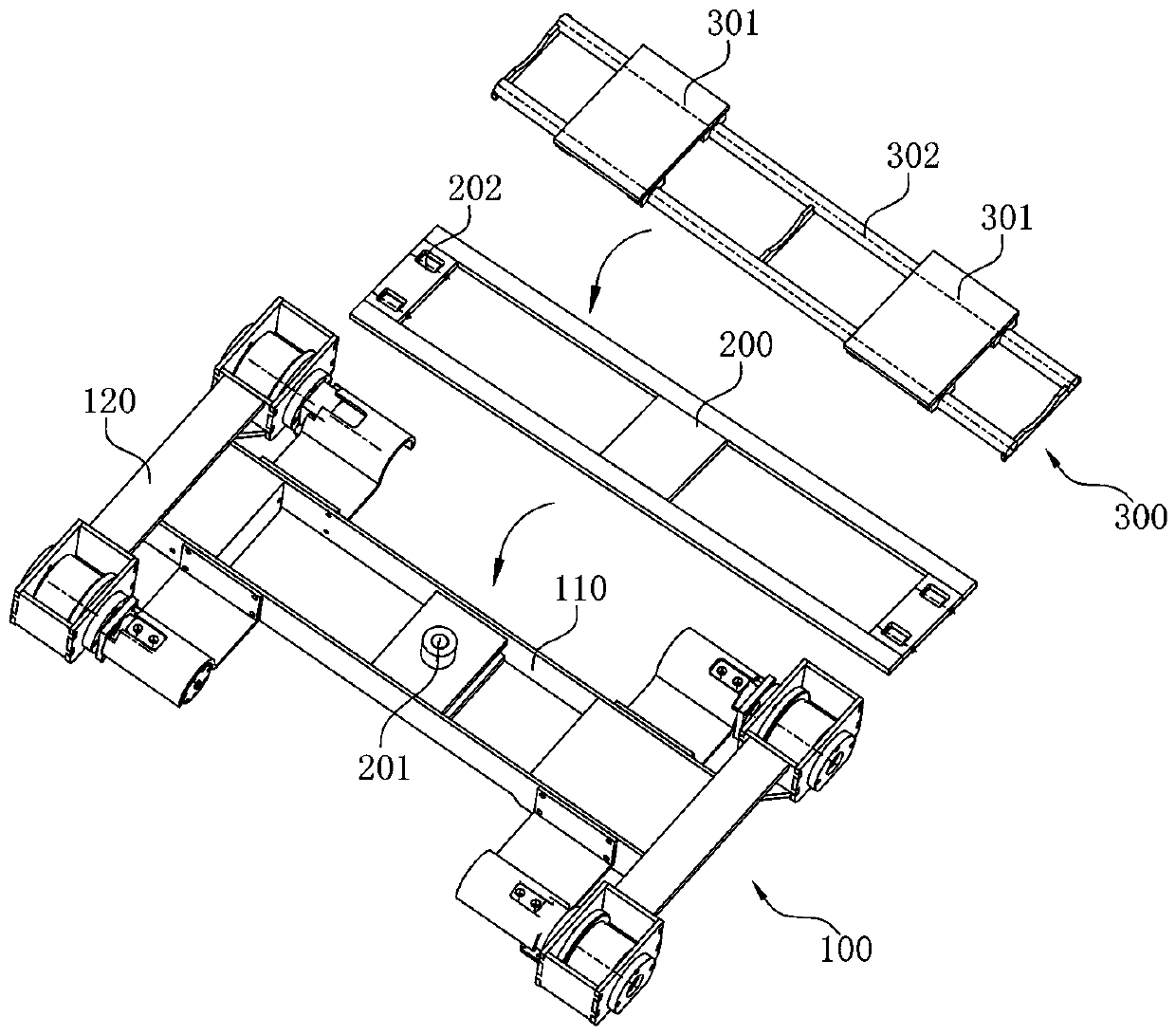

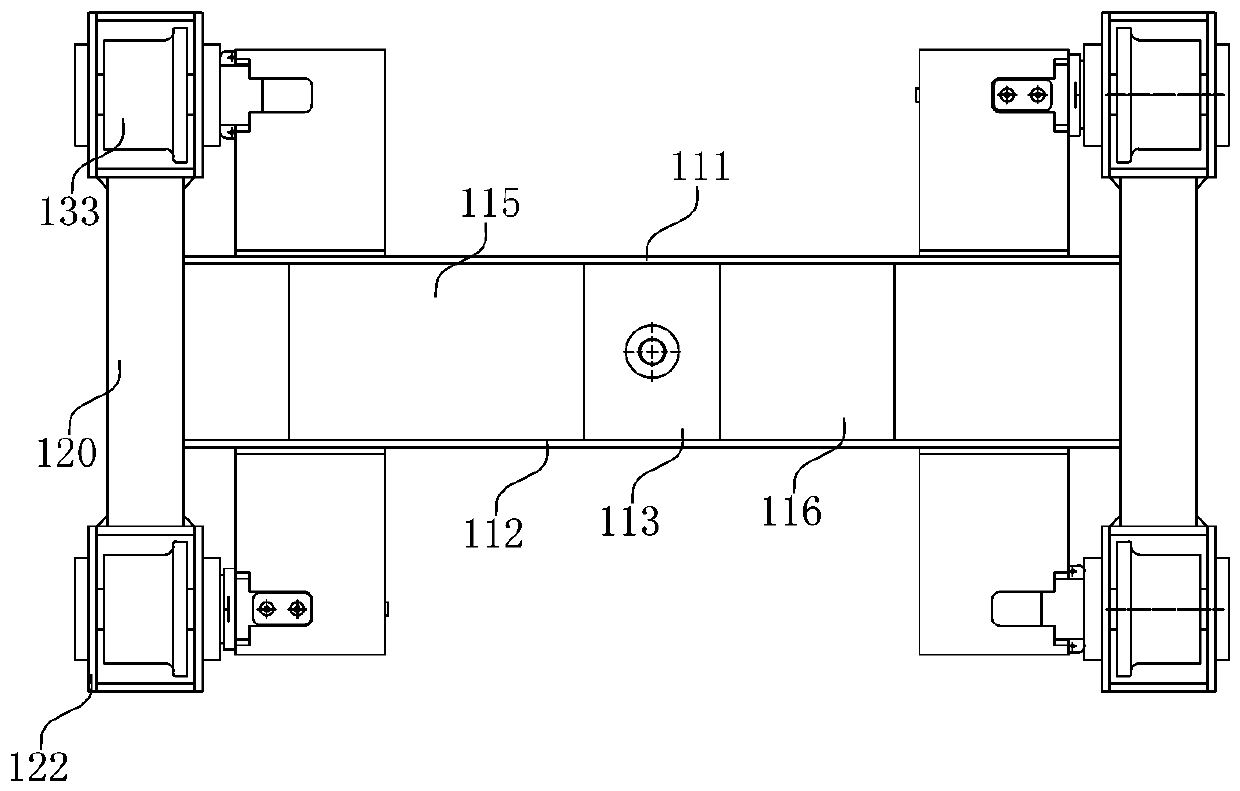

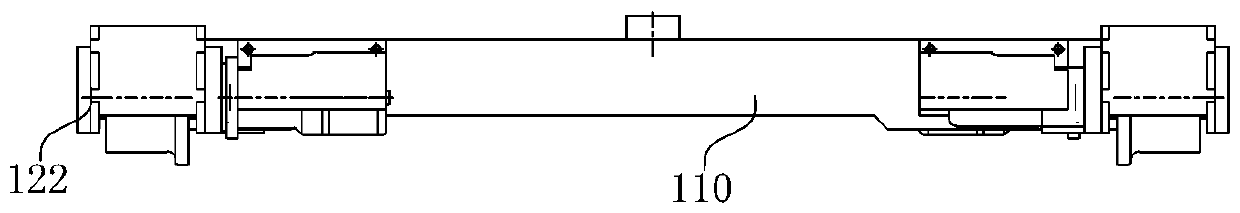

[0039] see Figure 1-Figure 12 , a turnout vehicle of the present invention, comprising a walking frame 100, a revolving frame 200 and a load-bearing frame 300, the bottom of the walking frame 100 is provided with a walking assembly; the rotary support of the revolving frame 200 is arranged on the walking frame 100; Set on the slewing frame 200, a load-bearing seat 301 is arranged on the load-bearing frame 300, and the load-bearing seat 301 is slidably arranged on the load-bearing frame 300. During the operation, the walking frame and the rotating frame are driven by the walking assembly The frame and load-bearing frame move and brake as a wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com