A construction method of turnable assembled stirrup and high flatness floor slab

A prefabricated, stirrup technology, which is applied in the processing of building materials, construction, building reinforcements, etc., can solve the problems of locally excessively thick underside of the floor, excessively thick local covering of the reinforced skeleton of the floor, and low flatness, etc. The effect of flatness, reducing deformation and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

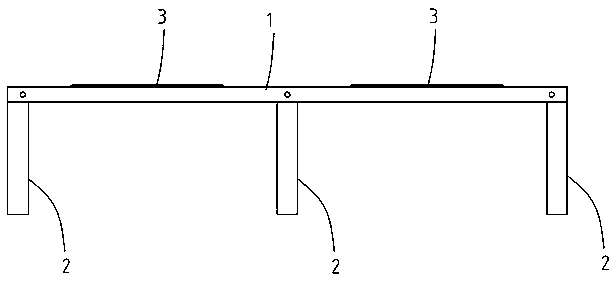

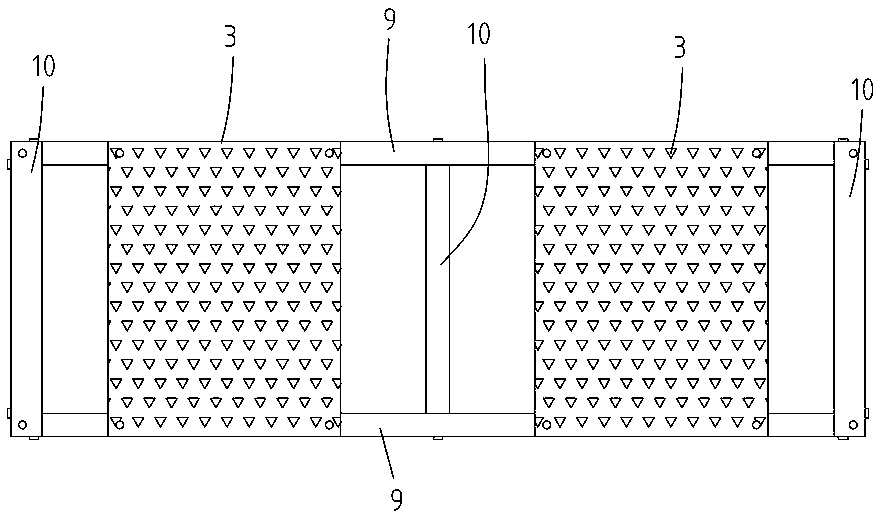

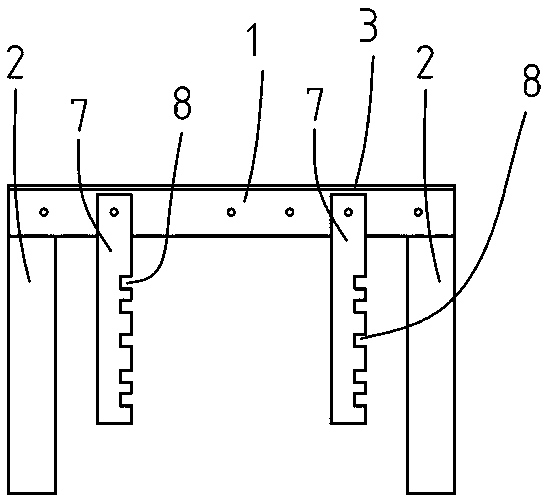

[0078] A method of floor construction using the stirrups of the above-mentioned embodiment, such as Figure 1-6 shown, including the following steps:

[0079] Step 1, pouring formwork 5 is erected;

[0080] Step 2, tying the reinforcement framework 6: binding the reinforcement framework 6 on the pouring formwork 5 of step 1;

[0081] Step 3, arranging the stirrups: place the stirrups on the pouring formwork 5 according to the design position of the stirrups, then lift the reinforcement frame 6, and make the negative reinforcement of the reinforcement frame 6 fit into the slot 8 of the stirrup clamping part 7;

[0082] Step 4. Concrete pouring: the construction workers perform concrete pouring on the floor 4 on the stirrups;

[0083] Step 5. Take out the stirrups: After the concrete construction is completed, take out the stirrups;

[0084] Step 6. Storing the stirrups: Rinse the stirrups taken out in step 5, and then store them for the next use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com