High-efficiency air temperature vaporizer

A vaporizer and high-efficiency technology, applied in the direction of pressure vessels, non-pressure vessels, container filling methods, etc., can solve the problems of low heat exchange efficiency, inability to achieve vaporization, and unsatisfactory heat exchange effects, so as to improve heat exchange efficiency, Easy to control, improve the effect of heat transfer efficiency and heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

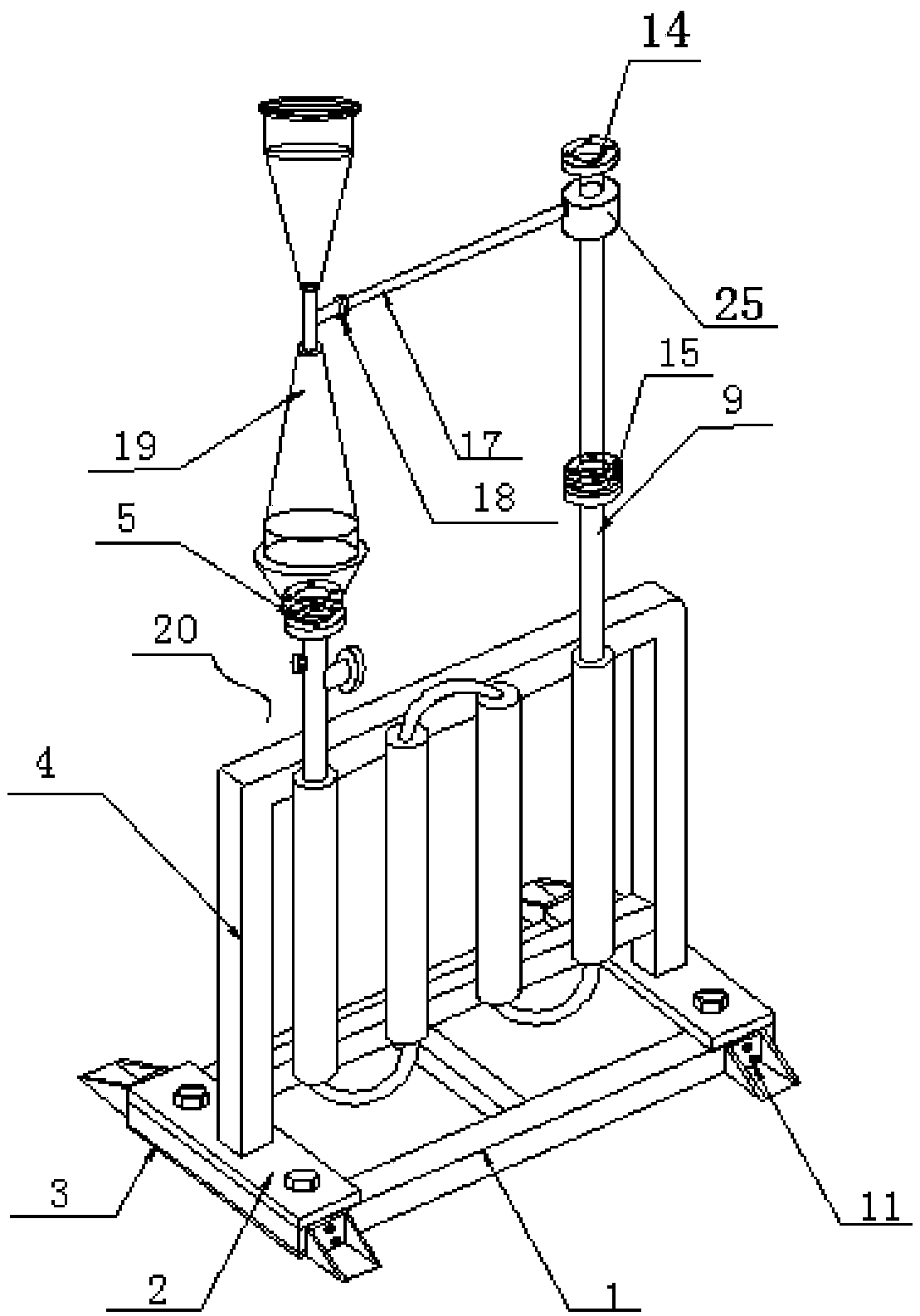

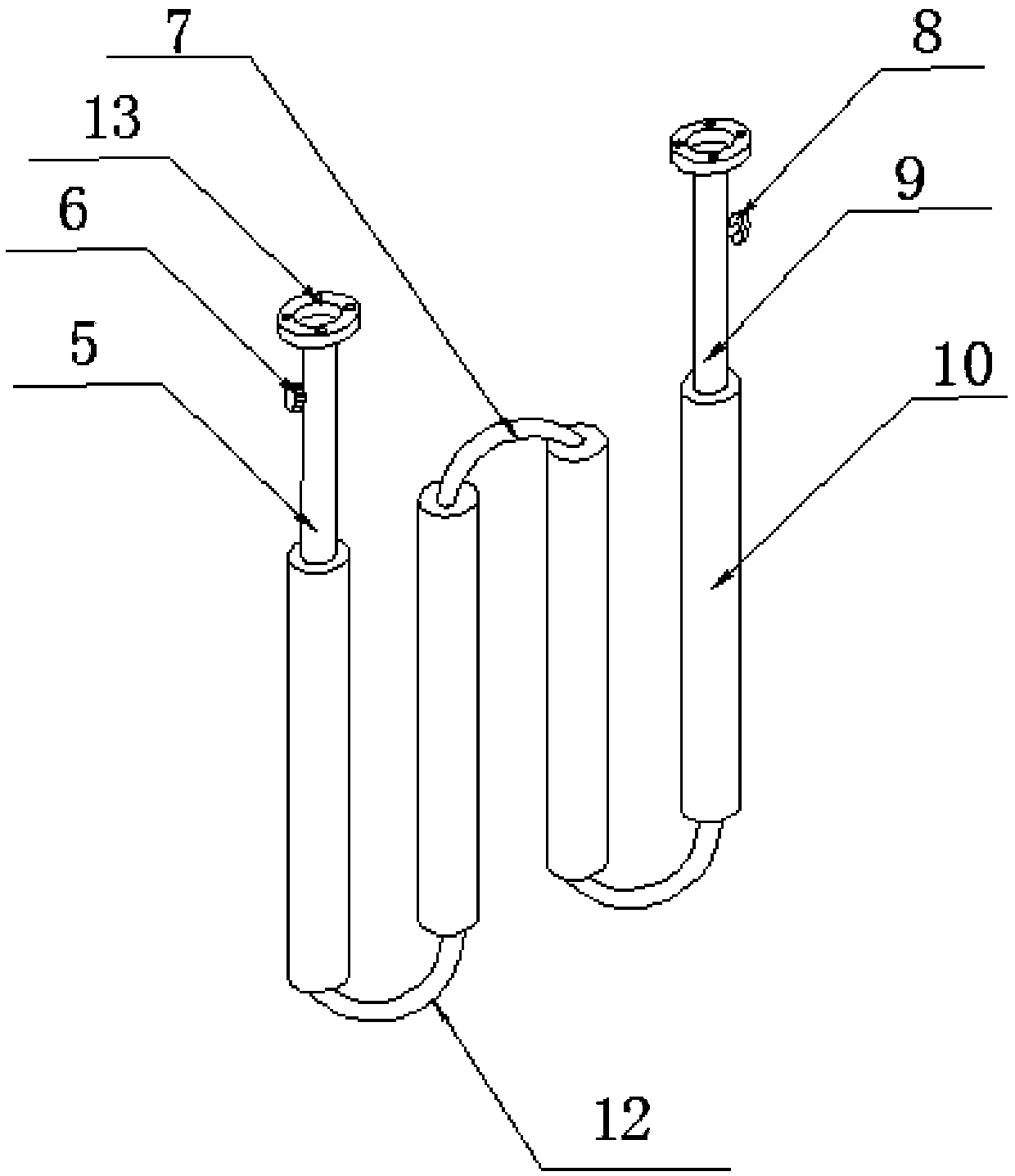

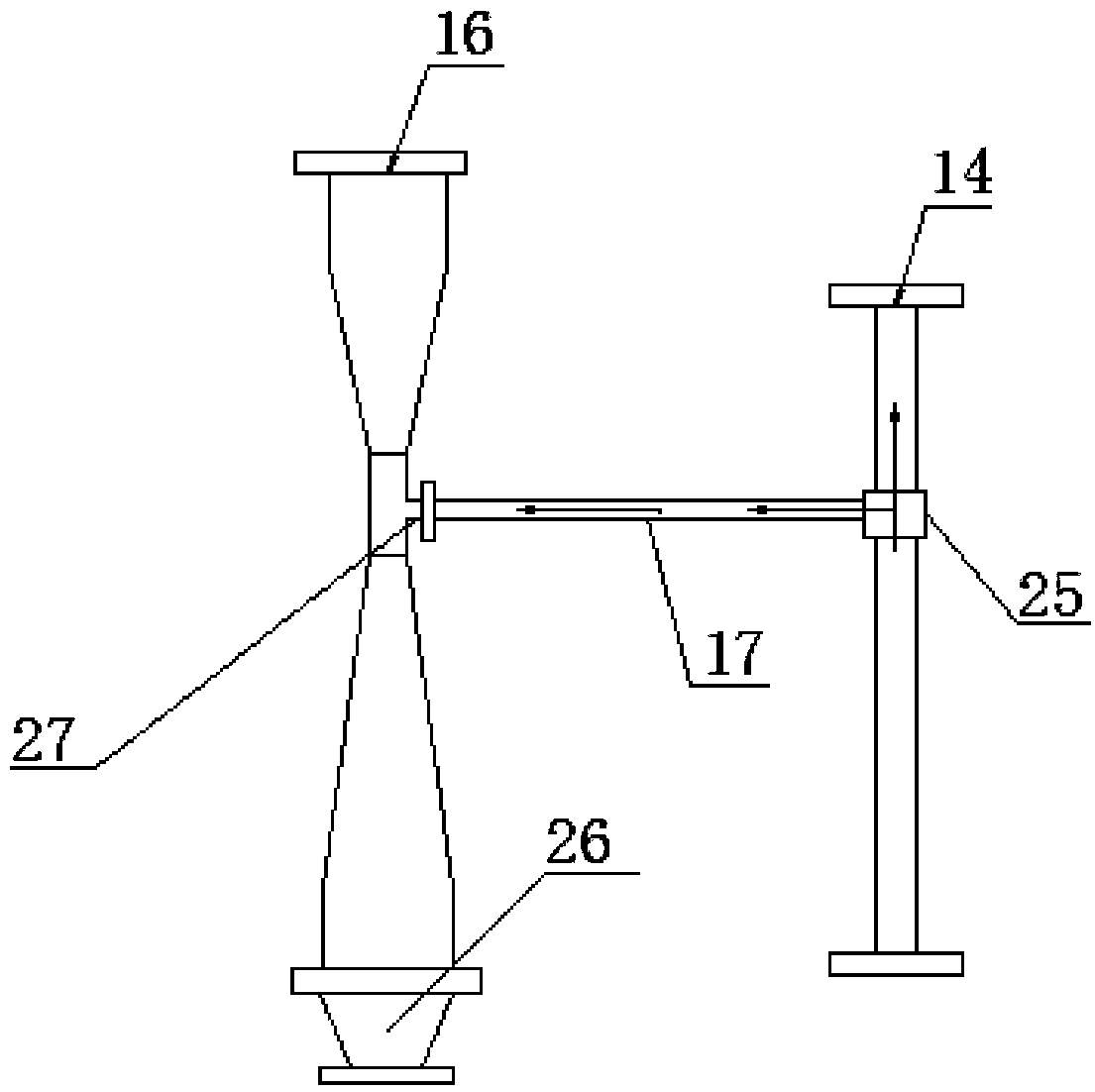

[0027] see Figure 1~4 , in the embodiment of the present invention, a high-efficiency air-temperature evaporator 20 includes a mounting and fixing assembly, a finned tube set 10 and a venturi tube 19, wherein the mounting and fixing assembly includes a mounting part and a fixing part, so The installation part is retractable so as to install and fix the carburetor, and the fixing part is used for fixing and arranging the finned tube assembly 10, one end of the finned tube group 10 is the inlet 5 of the carburetor, so The other end of the finned tube group 10 is the vaporizer outlet 9, which is characterized in that,

[0028] The vaporizer inlet 5 is connected with the Venturi tube 19 by an inlet flange 13, and the vaporizer outlet 9 is connected with an extended outlet pipe by an outlet flange 15, and the middle of the outlet pipe and the Venturi tube 19 is An inlet and outlet connecting pipe 17 is also connected between the negative pressure ports of the throat, so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com