Automatic disengaging and engaging projectile hoist

An automatic clutch and bomb lifter technology, applied in the direction of ammunition supply, weapon accessories, launchers, etc., can solve the problems of no bomb supply speed, greatly reduced bomb supply resistance, affecting the work of the automaton, etc., to achieve a simple structure, guaranteed The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

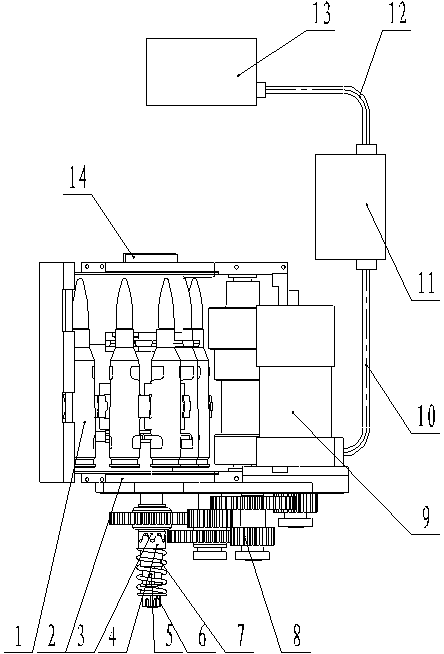

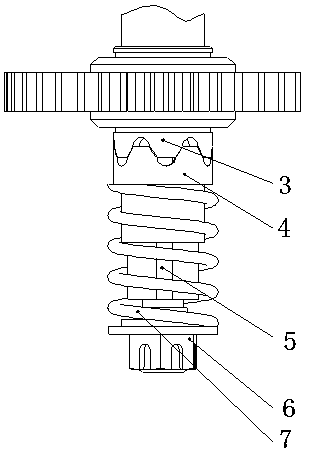

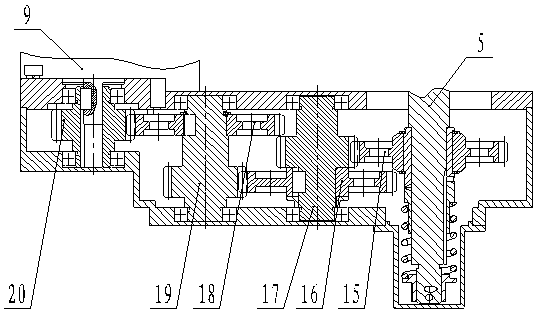

[0022] exist figure 1 Among them, the bomb lifting device 2, the reducer 8, the motor 9, the control cable 10, the controller 11, the power cable 12, and the power supply 13 are connected in sequence. One end of the clutch composed of the clutch fixed block 3, the clutch moving block 4, the transmission shaft 5, the adjusting nut 6 and the adjusting spring 7 is connected with the spring lifting device 2, and the other end is connected with the speed reducer 8. Usually controller 11 outputs a shooting signal and transmits to motor 9 through control cable 10, and motor is transmitted to clutch after speed reducer 8 decelerates, and whether clutch transmits torque according to the resistance size of bullet supply. The torque transmitted by the clutch drives the bullet lifting device 2 to start lifting the bullet, and after the bullet is lifted, under the action of the ratchet mechanism 14, the belt bullet chain 1 is prevented from reversing.

[0023] exist figure 2 In the show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com