Spherical motor rotor location detection method based on Hall elements

A technology of rotor position detection and Hall element, applied in electrical components, electromechanical devices, electrical devices, etc., can solve the problems of inconvenient system operation, large system volume, increased frictional resistance, etc., and achieve simple hardware structure and solution speed. Fast, high coverage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention provides a design method of a Hall element-based spherical motor rotor position detection system, and verifies its accuracy through a three-axis turntable. The present invention will be described in detail below in conjunction with the accompanying drawings and examples. Concrete implementation steps of the present invention are as follows:

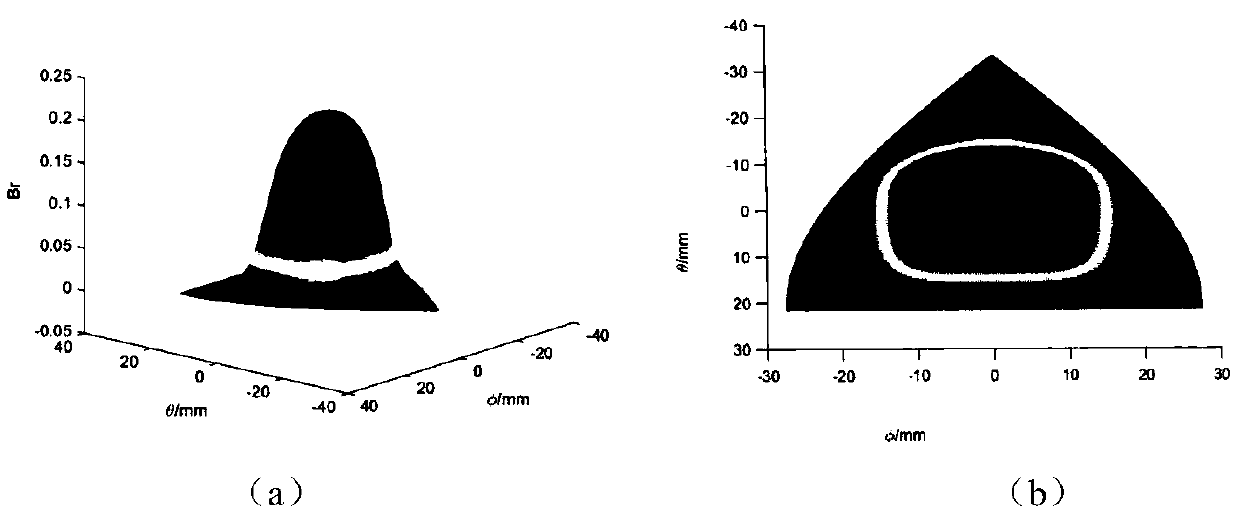

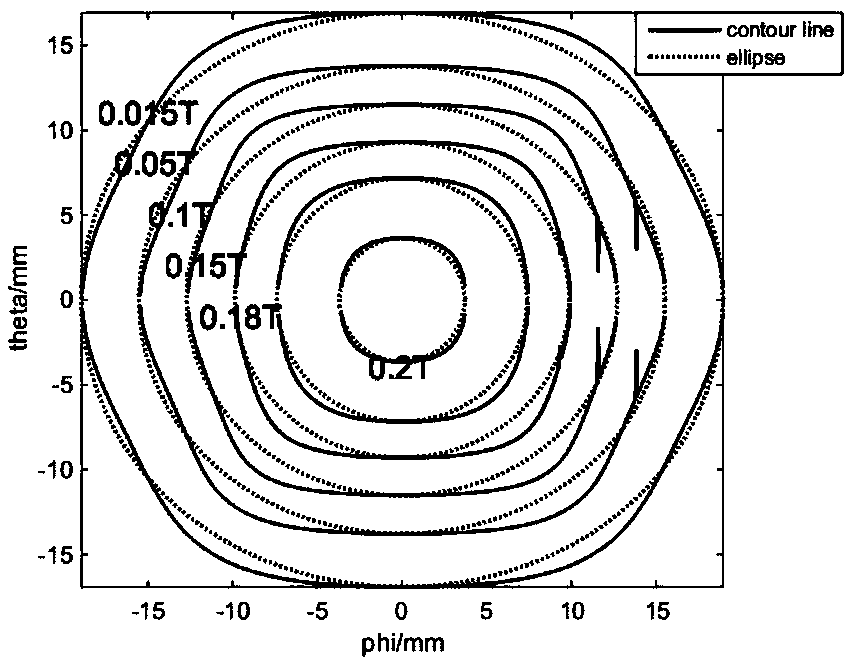

[0032] (1) Establish the surface magnetic field expression of the spherical motor rotor, and then solve the spatial radial magnetic field matrix of the entire rotor spherical surface according to the magnetic field expression.

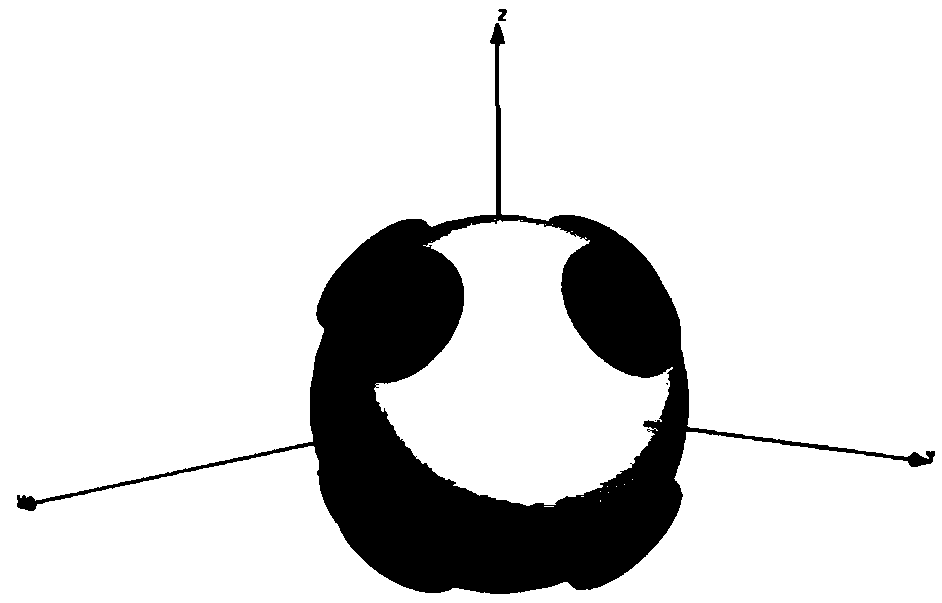

[0033] The spherical motor rotor model studied in this patent is based on the paper (Li B, Li Z, Li G. Magnetic Field Model for Permanent Magnet Spherical Motor with Double Polyhedron Structure [J]. IEEE Transactions on Magnetics, 2017, PP(99): 1-1 .) The spherical motor structure proposed in , which contains 8 permanent magnet poles, and its N and S stages are alternately distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com