Fretting fatigue test device for high temperature rotating bending fatigue testing machine

A technology of bending fatigue and fretting fatigue, which is applied in the direction of measuring devices, using applied repetitive force/pulsation force to test the strength of materials, instruments, etc. It can reduce the uncontrollable factors, eliminate the influence of load, and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

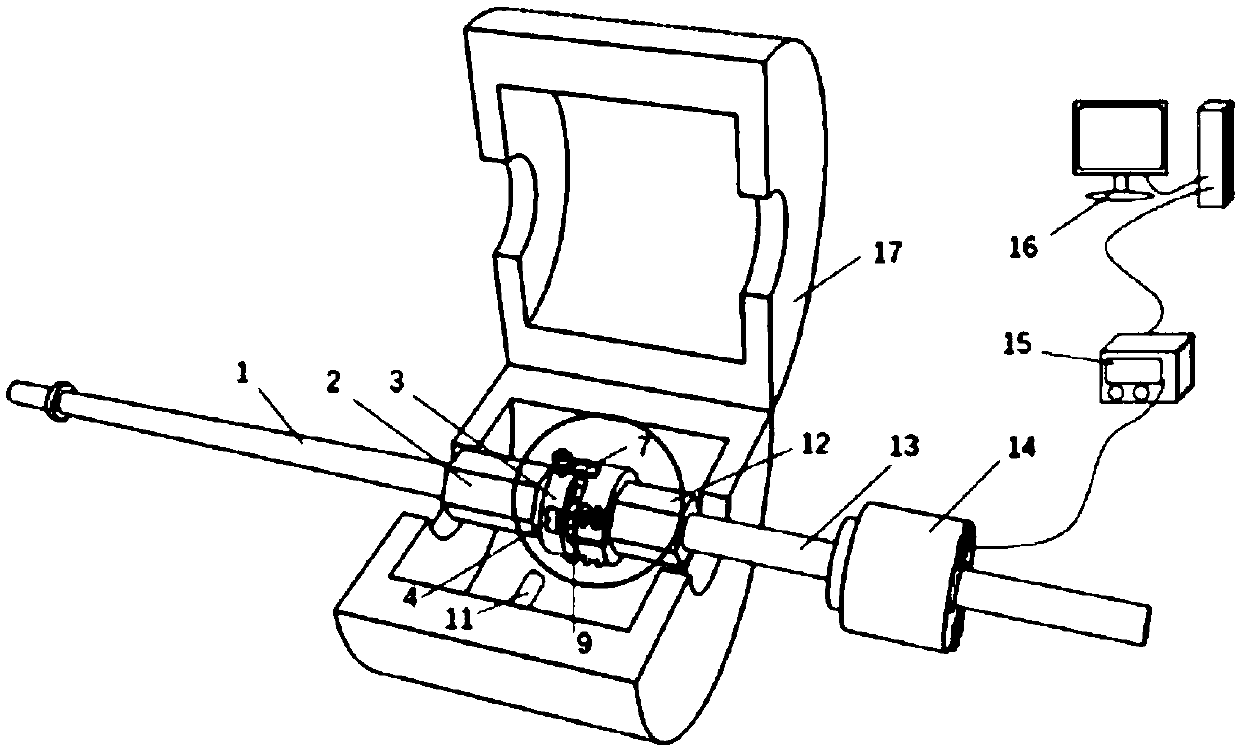

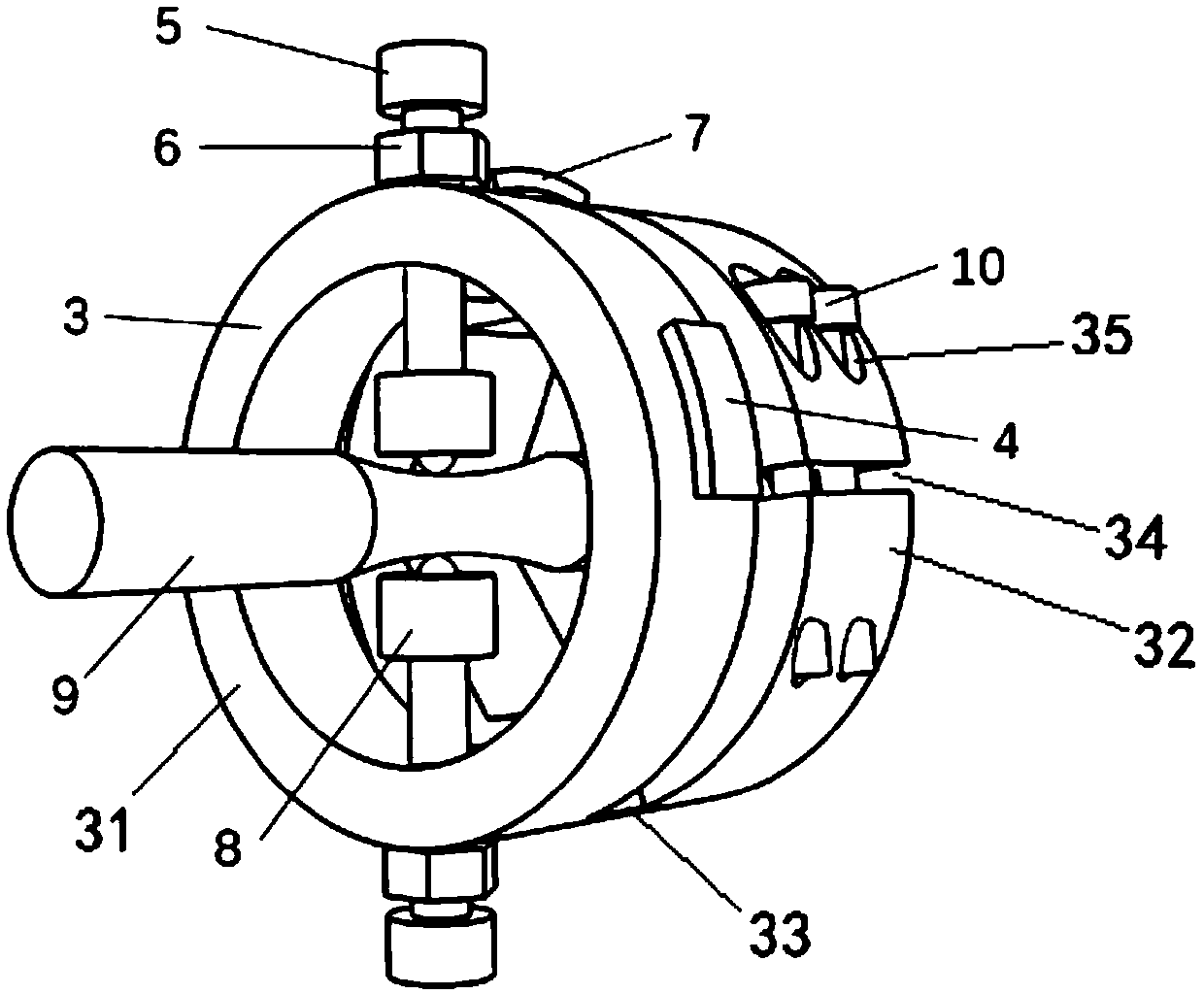

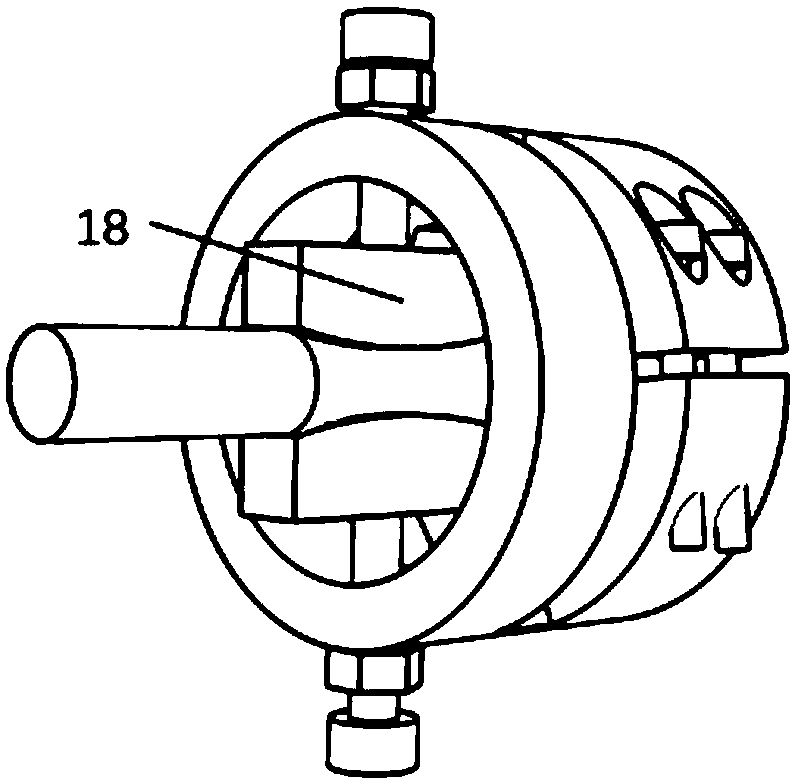

[0027] A fretting fatigue test device suitable for a high-temperature rotating bending fatigue testing machine can be used for research on the high-temperature rotating bending fretting fatigue performance of materials and the performance of surface-treated materials against high-temperature rotating bending fretting fatigue. see figure 1 , the fretting device can be placed in the resistive single-stage high-temperature furnace 17 matched with the rotary bending fatigue testing machine, and specifically includes a supporting stress loading ring 3, two symmetrical ring walls passing through the loading ring 31 in the supporting stress loading ring 3 The loading bolt 5, the ceramic fretting test block 8 in contact with the fatigue sample 9, the high-temperature strain gauge 4 for measuring the normal contact load, the high-temperature strain gauge 7 for measuring the tangential contact load, and the conductive slip ring 14 connected to it, the strain gauge Instrument 15 and comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com