A kind of packaging material and its application

A packaging layer and chip packaging technology, applied in circuits, electrical solid devices, semiconductor devices, etc., can solve the problem of reducing the flexibility of silicone rubber, and achieve the effect of reducing thermal stress, excellent thermal conductivity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

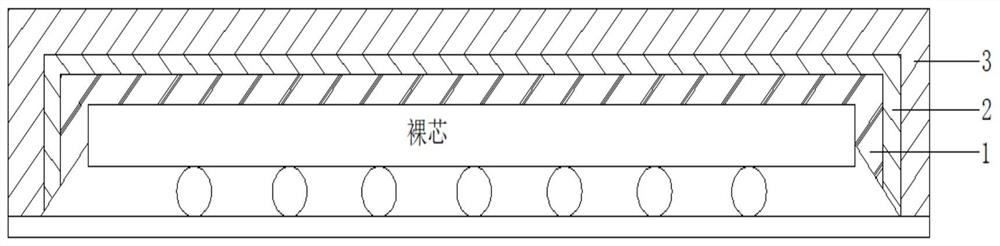

[0022] see figure 1 , the present embodiment provides a packaging material, including a flexible packaging layer 1, an intermediate packaging layer 2 and a high-strength packaging layer 3 stacked in sequence, the flexible packaging layer includes a thermoplastic polymer and 10wt% thermally conductive filler, the middle packaging layer Including thermoplastic resin, the high-strength encapsulation layer includes high-strength material and 10wt% thermally conductive filler, the high-strength material is used to provide physical protection for the packaged object, the thermoplastic polymer used in this embodiment is butyl rubber, thermally conductive filler It is hexagonal boron nitride fiber, the thermoplastic resin is polyethylene, and the high-strength material is epoxy resin.

[0023] This embodiment also provides a method for preparing the above-mentioned packaging material by 3D printing, including the following steps:

[0024] (1) Establish a model of the packaging struct...

Embodiment 2

[0030] This embodiment provides a packaging material, including a flexible packaging layer, an intermediate packaging layer and a high-strength packaging layer stacked in sequence, the flexible packaging layer includes a thermoplastic polymer and 90wt% thermally conductive filler, and the thermoplastic polymer is silicone rubber The thermoplastic polymer phenyl vinyl silicone rubber, the thermally conductive filler is carbon fiber, the intermediate packaging layer includes thermoplastic resin, the thermoplastic resin is polyvinyl chloride, and the high-strength packaging layer includes high-strength material and 10wt% thermally conductive filler, so The high-strength material is polylactic acid, the thermally conductive filler is graphene fiber, and the high-strength material is used to provide physical protection for the packaged object.

Embodiment 3

[0032] This embodiment provides a packaging material, including a flexible packaging layer, an intermediate packaging layer and a high-strength packaging layer stacked in sequence, the flexible packaging layer includes a thermoplastic polymer and 20wt% thermally conductive filler, and the thermoplastic polymer is polydimethyl Silicone-based PDMS, the thermally conductive filler is aluminum nitride, the intermediate packaging layer includes thermoplastic resin, the thermoplastic resin is polyvinyl chloride, the high-strength packaging layer includes high-strength materials and 90wt% thermally conductive filler, the high The strength material is polylactic acid, the heat-conducting filler is silicon carbide, and the high-strength material is used to provide physical protection for the encapsulated object.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com