Rotor support structure of permanent magnet spherical motor

A spherical motor and rotor support technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of small output torque, stator spherical shell collision, poor stability, etc., to reduce the contact area , reduce friction, high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

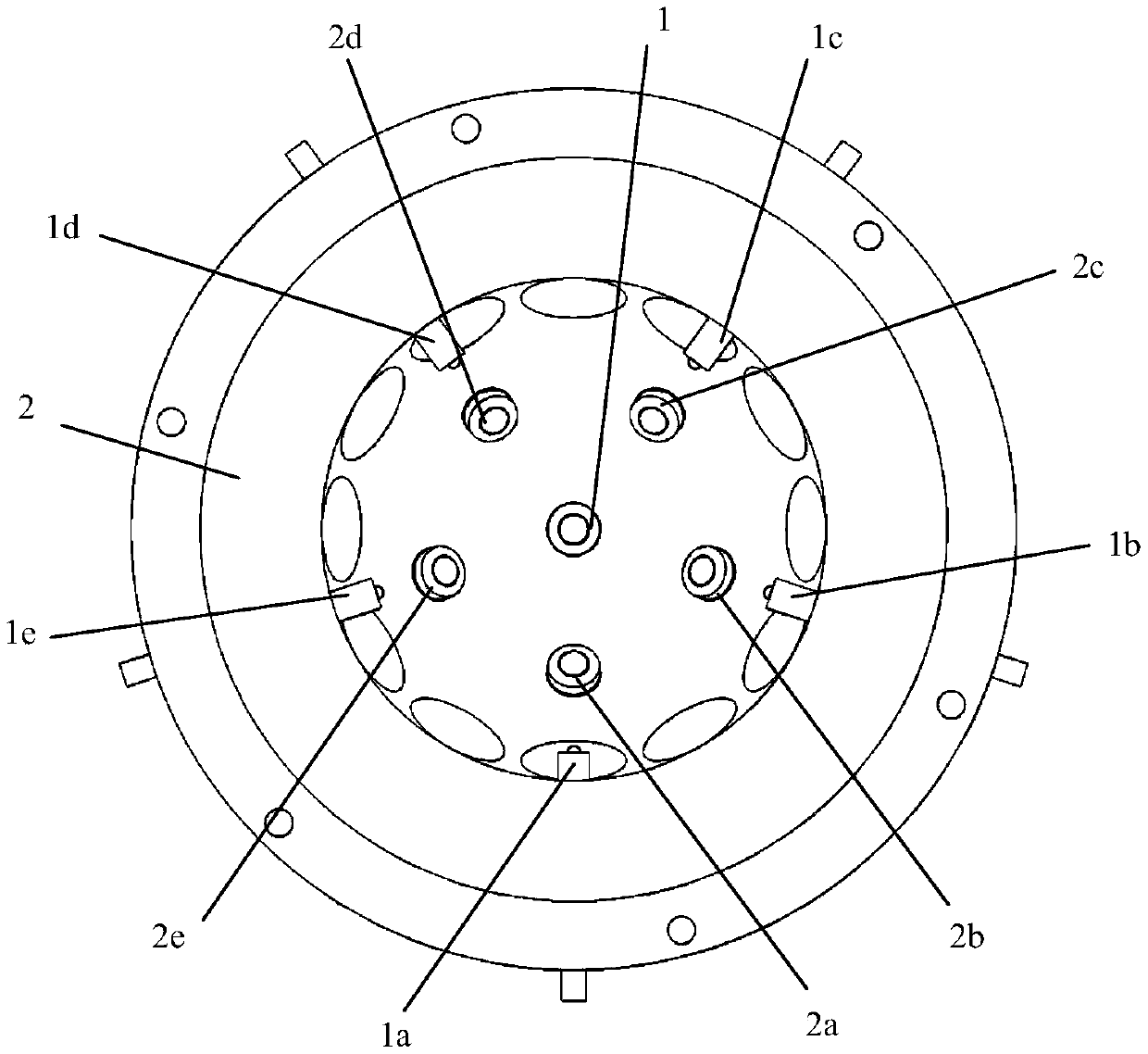

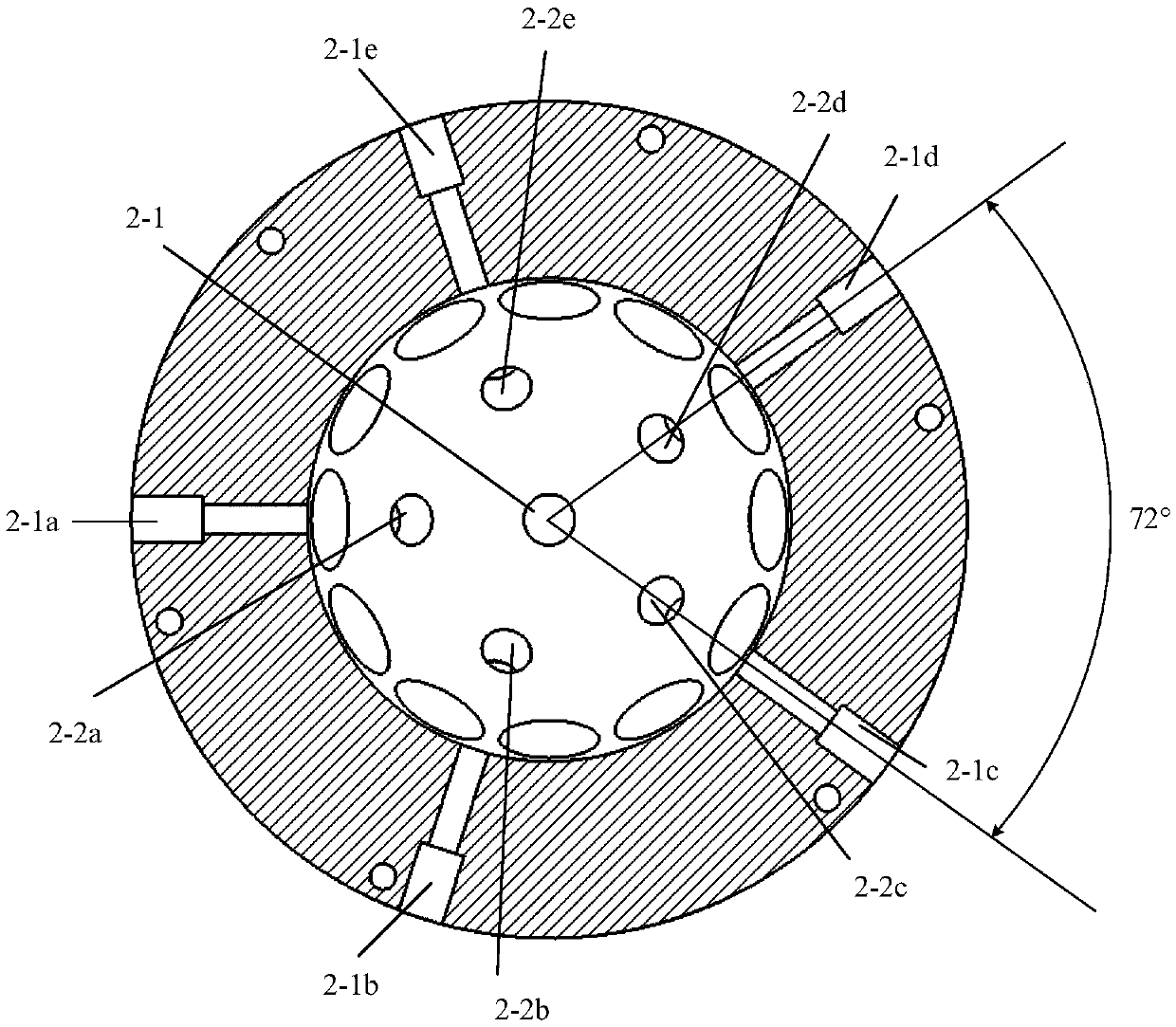

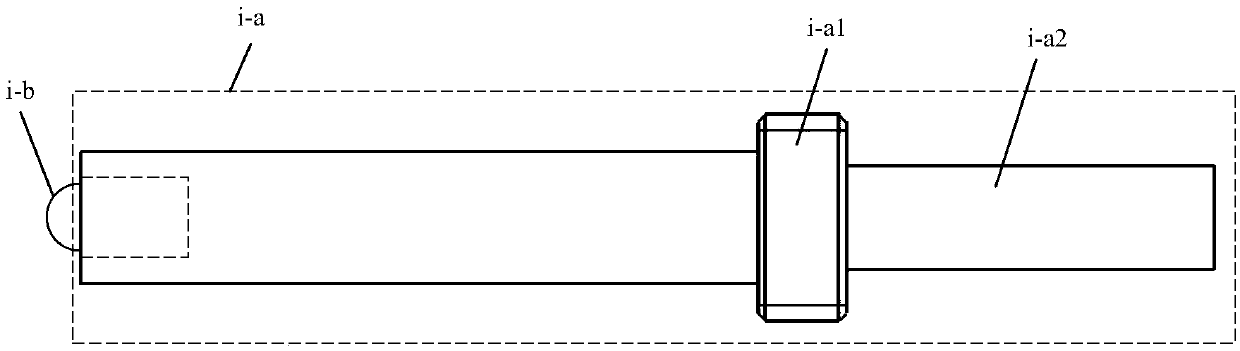

[0023] refer to Figure 1 to Figure 4 , a permanent magnet spherical motor rotor support structure, characterized in that the support structure includes an equatorial surface support column group, a side support column group, a bottom surface support column 1, and a stator lower casing 2. The equatorial support column group includes five identical equatorial support columns, namely the first equatorial support column 1a, the second equatorial support column 1b, the third equatorial support column 1c, the fourth equatorial support column 1d, the Five equatorial support columns 1e, installed in the first mounting hole 2-1a, the second mounting hole 2-1b, the third mounting hole 2-1c, the fourth mounting hole 2-1d, the fifth Mounting hole 2-1e. The side support column group includes 5 identical side support columns, namely the first side support column 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com