Beef tendon noodle continuous production and processing system

A processing system and technology of beef gluten noodles, applied in the direction of dough processing, dough extruder, dough forming and cutting equipment, etc., can solve the problems of unsatisfactory conditions, low production efficiency, large randomness, etc., and achieve low processing efficiency , mellow aftertaste, soft and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the scope of protection of the present invention is not limited to the following Described embodiment.

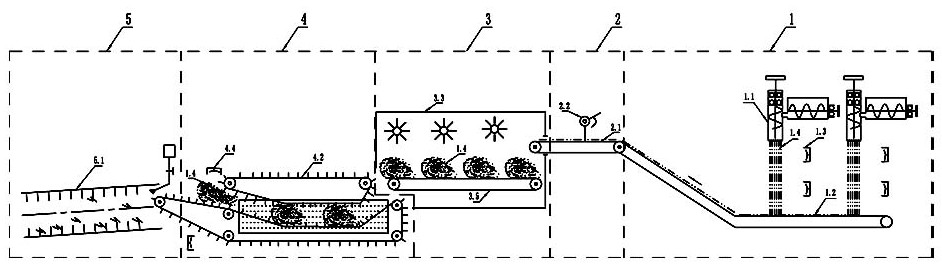

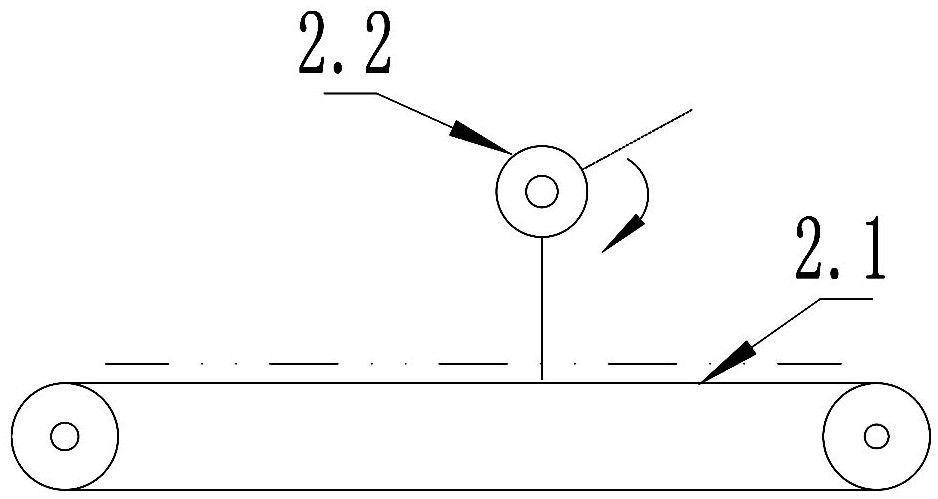

[0026] Such as figure 1 As shown, the continuous production and processing system for beef tendon noodles of the present invention includes a beef tendon noodle cutting unit 1 , a cutting unit 2 , a resting noodle disinfection unit 3 , a soaking unit 4 , and an oiling unit 5 .

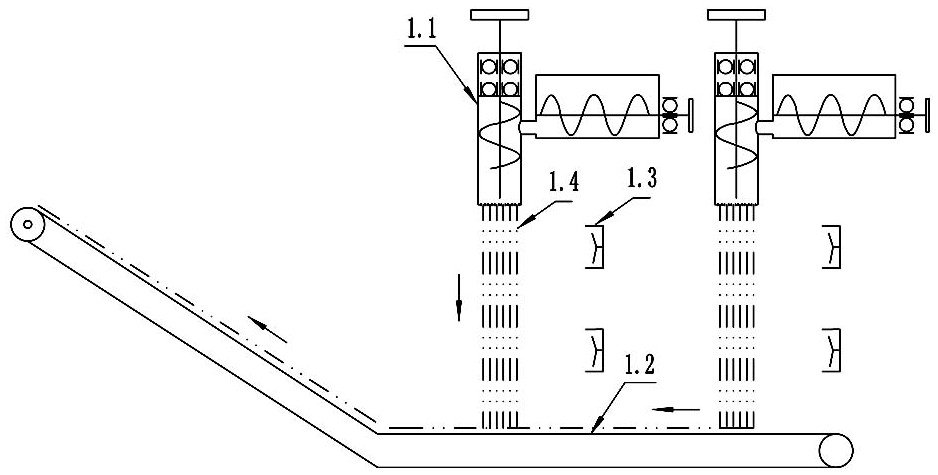

[0027] Such as figure 2 Shown, described unloading unit 1 comprises the beef tendon noodle extruder 1.1 that discharge port is arranged downward, is provided with the first conveyor belt 1.2 at 700 millimeters below the discharge port of beef tendon noodle extruder 1.1, is positioned at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com