Wind fire-extinguishing device for fire-fighting robot used in narrow and small space

A fire-fighting robot and technology for small spaces, applied in the field of intelligent equipment, can solve problems such as large chassis size, and achieve the effect of promoting reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

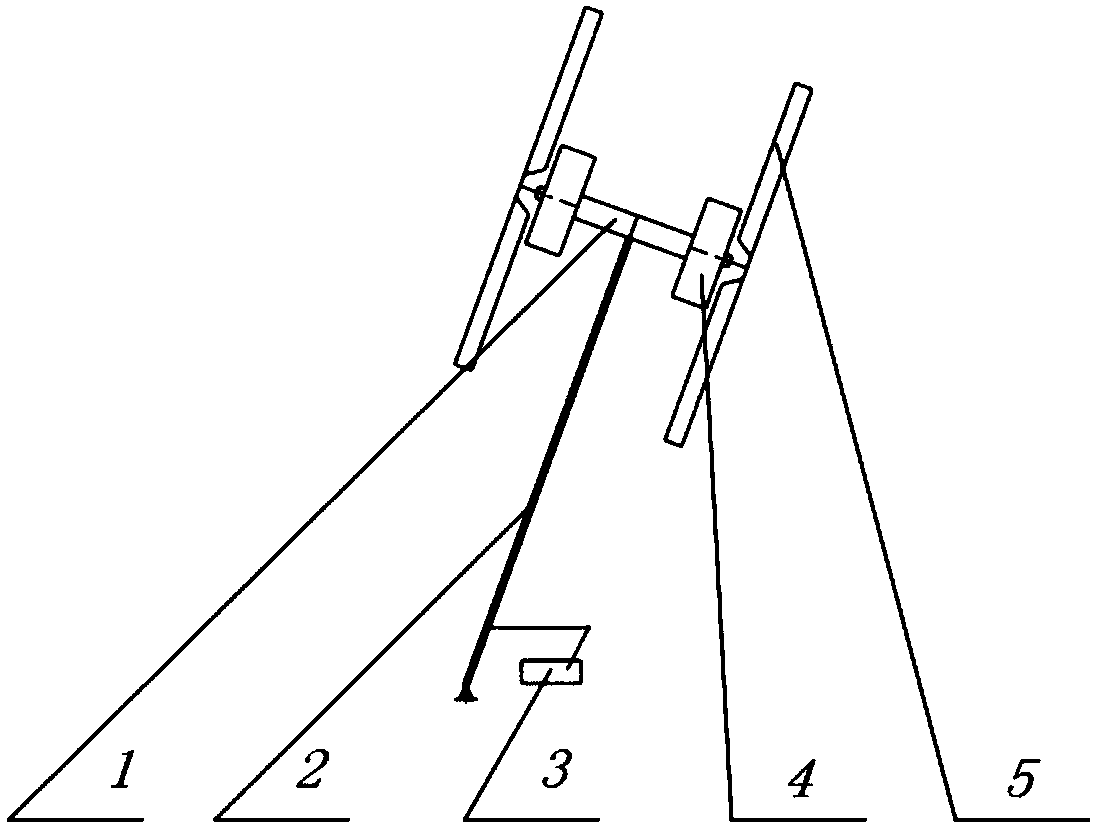

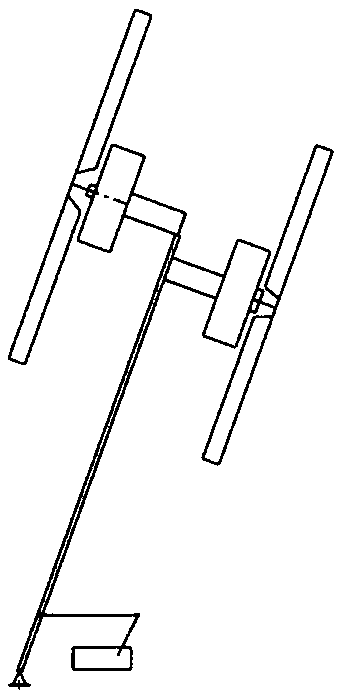

[0033] Such as figure 1 As shown, a wind fire extinguishing device for a fire extinguishing robot in a narrow space described in this embodiment includes a group of two motors, an electronic speed controller, a mounting base, a mounting arm and a steering gear for driving the mounting arm, and the two motors are respectively Located on both sides of the mounting base, the propellers are connected to their respective motors to drive, the mounting arm is connected to the mounting base, and the steering gear that drives the mounting arm. A group of two motors are symmetrically installed on the mounting base, each motor drives a propeller to generate fire-extinguishing wind, the two motors and the propellers driven by them turn in opposite directions, and the direction of the fire-extinguishing wind blows to both sides. The mounting arm is driven by the servo to change the wind direction of the two motors, thereby realizing fire extinguishing.

[0034]Further, if the two motors a...

Embodiment 2

[0041] The only difference between this embodiment and Embodiment 1 is that the axes of the two motors are installed in a misaligned position, and the specific parameters are as follows: (1) The position of the two screw drive assemblies (motor, propeller) relative to the rotatable end of the mounting arm The vector sum of the generated torque is less than 5% of the maximum output torque of the steering gear; (2) The selection of parameters such as the rotational speed of the two motors meets the parameter selection rules mentioned above. Generally speaking, the distance between the axes of the two motors is 0.2-0.45 times the diameter of the two propellers.

Embodiment 3

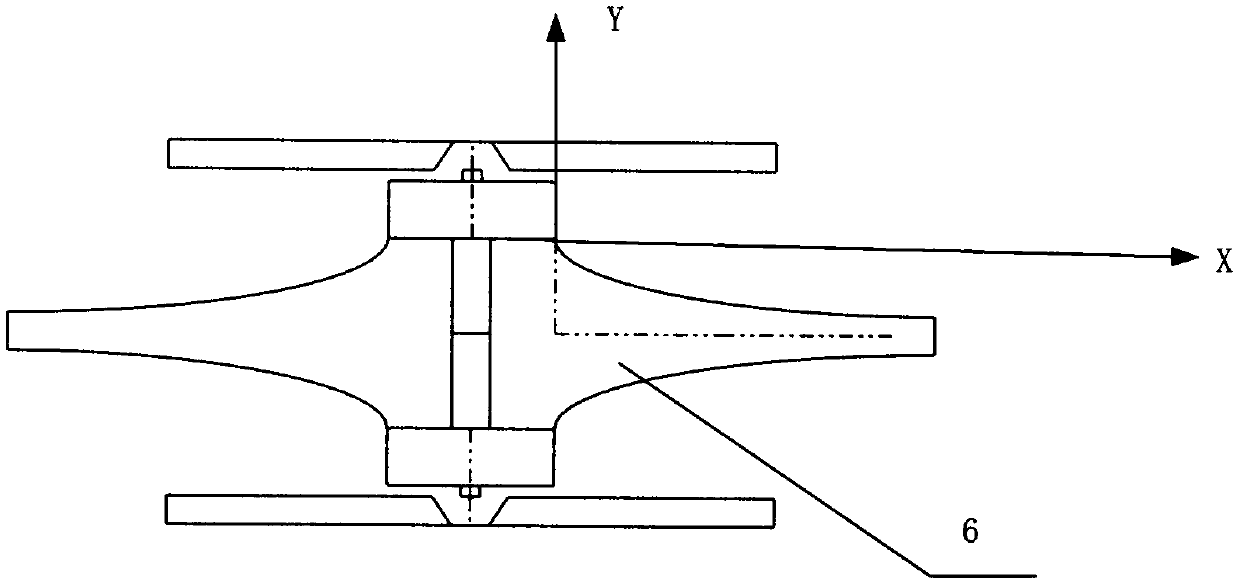

[0043] The difference between this embodiment and Embodiment 1 is that a rectifier is installed between the two motors, and the rectifier is formed by rotating a parabola around the motor axis. A two-dimensional coordinate system is established with the vertices of the parabola. The Y axis of the two-dimensional coordinate system is parallel to the axis of the power output shaft of the motor, and the mounting arm points to the motor. The parabolic equation can be expressed by y 2 =-2px, where the value of p is 0.25~0.3d, and d is the distance from the blade tip track circle to the mounting seat when the propeller rotates.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap