A powder classification system

A classification system and powder technology, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as unreliable accuracy, lower limit of sieving, low efficiency of fine particle sieving, and achieve high efficiency and high precision Multi-level grading, the effect of controllable multi-level grading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

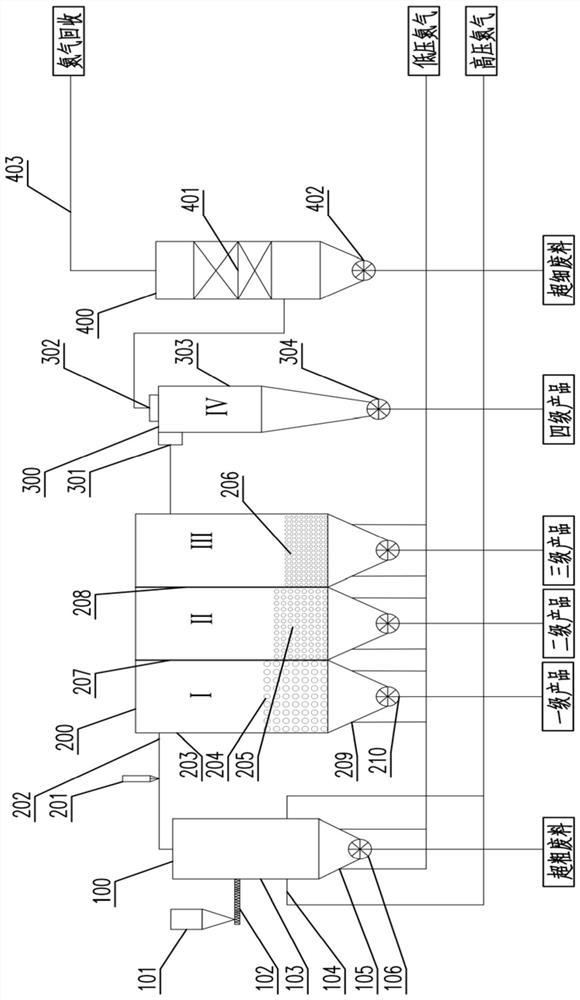

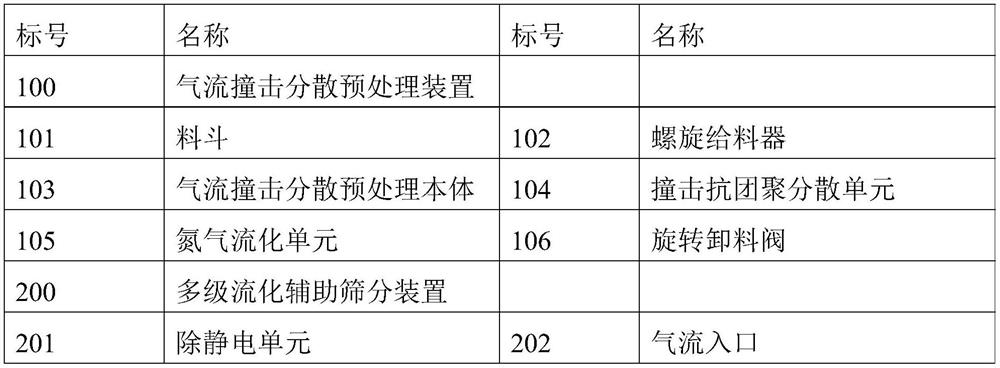

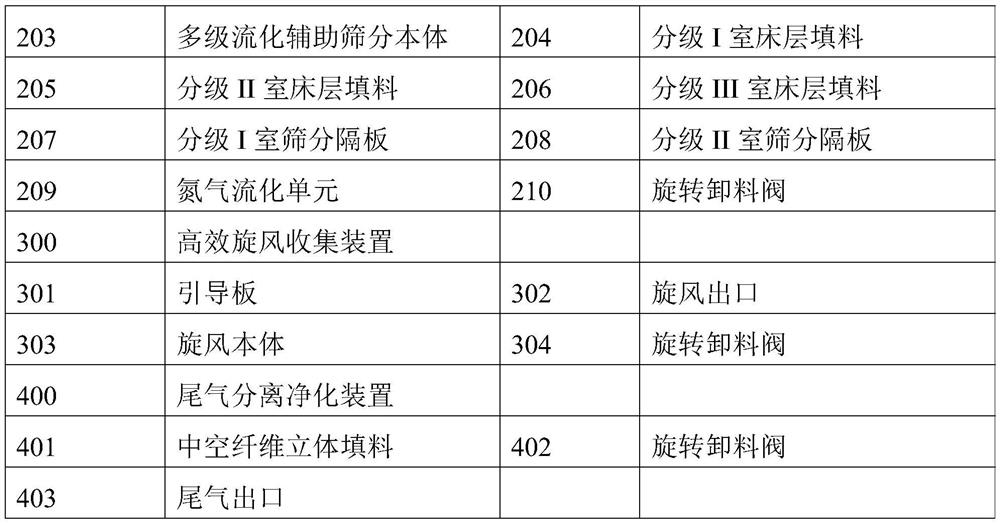

[0026] Such as figure 1 As shown, a powder classification system includes: a hopper 101 connected in sequence, a screw feeder 102, an airflow impingement dispersion pretreatment device 100, a multi-stage fluidized auxiliary screening device 200, a high-efficiency cyclone collection device 300 and an exhaust gas Separation and purification device 400;

[0027] Wherein, the airflow impingement dispersion pretreatment device 100 includes an airflow impingement dispersion pretreatment body 103, a nitrogen fluidization unit 105 is arranged below it, and the airflow impingement dispersion pretreatment body 103 contains an airflow distribution plate and an impact anti-agglomeration Dispersion unit 104, the impact anti-agglomeration dispersion unit 104 is connected to high-pressure nitrogen, the nitrogen fluidization unit 105 is connected to low-pressure nitrogen, and a rotary discharge valve 106 is provided below it;

[0028] The multi-stage fluidized auxiliary screening device 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com