Punching device

A punching device and punching technology, applied in the field of punching, can solve the problems of affecting the brazing quality, low product qualification rate, deviation of the branch tube core and the flanging hole core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

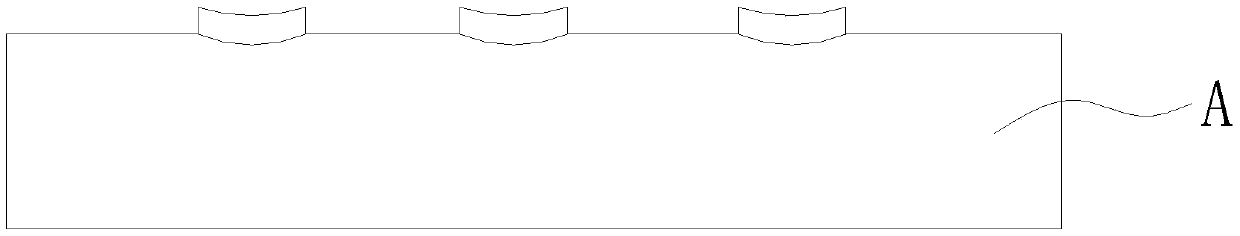

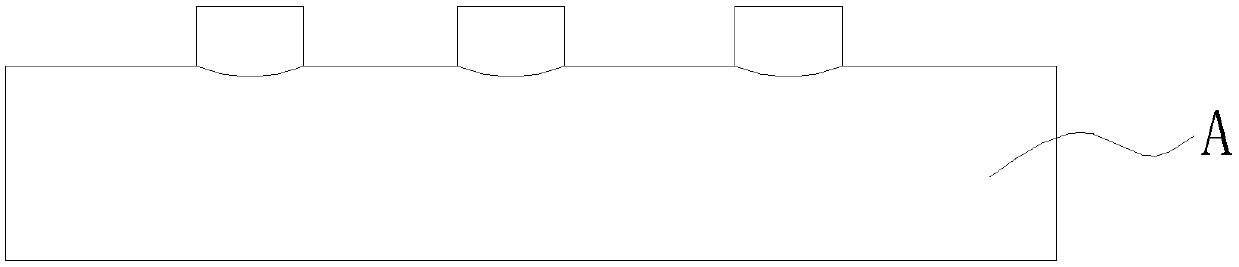

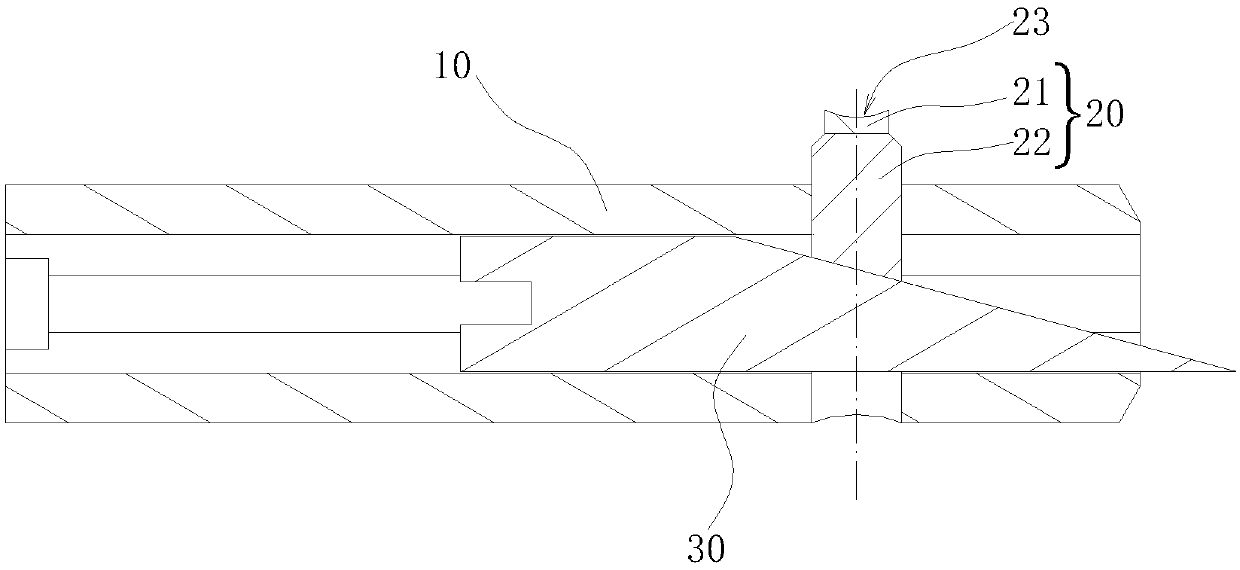

[0012] In conjunction with the accompanying drawings, a punching device includes a tube mold 10 inserted into the lumen of the pipe A to be punched, and a punch 20 is provided at the through hole provided on the tube wall of the tube mold 10, and the punch 20 is placed on the tube wall of the tube mold 10. Protruding and retracting movements are made in the through hole perpendicular to the direction of the pipe die 10. The end 21 of the punch 20 outside the pipe die 10 is an elliptical column whose long axis is consistent with the direction of the pipe die 10. The end surface is concave. The curved punching surface 23 and the center line of curvature of the concave arc punching surface 23 are perpendicular to the tube core of the pipe mold 10 . In the present invention, the end face of the end 21 of the punch 20 is set as a concave arc-shaped punching surface 23, so that the contour of the end 21 of the punch 20 can form a knife edge, so as to be used for shearing the wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com