Die for flaring of pipe fitting

A technology for molds and pipe fittings, applied in the field of molds for pipe flares, can solve the problems of consuming workers' time and energy, reducing the processing efficiency of enterprises, increasing production costs, etc., and achieving the effects of improving efficiency, improving yield and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

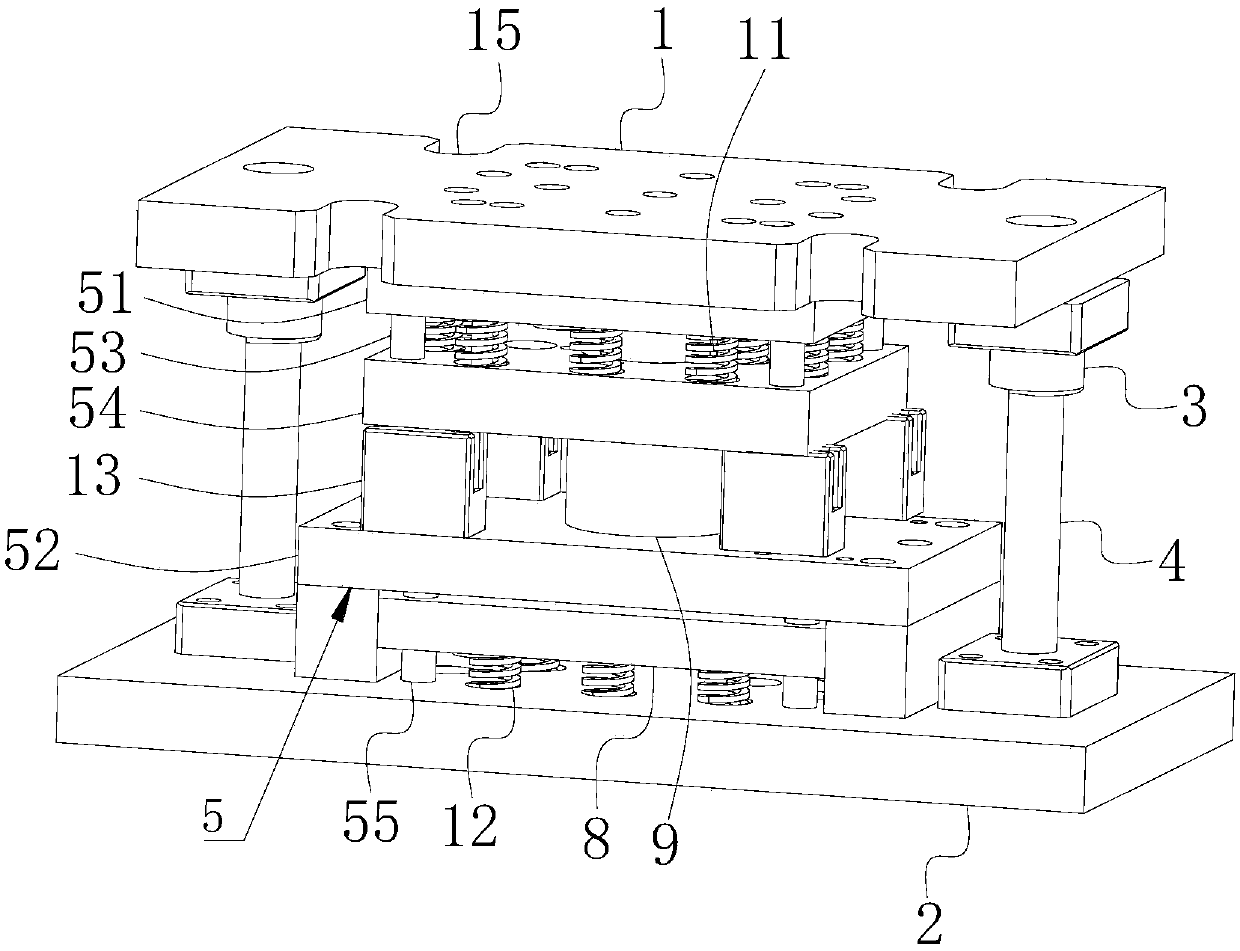

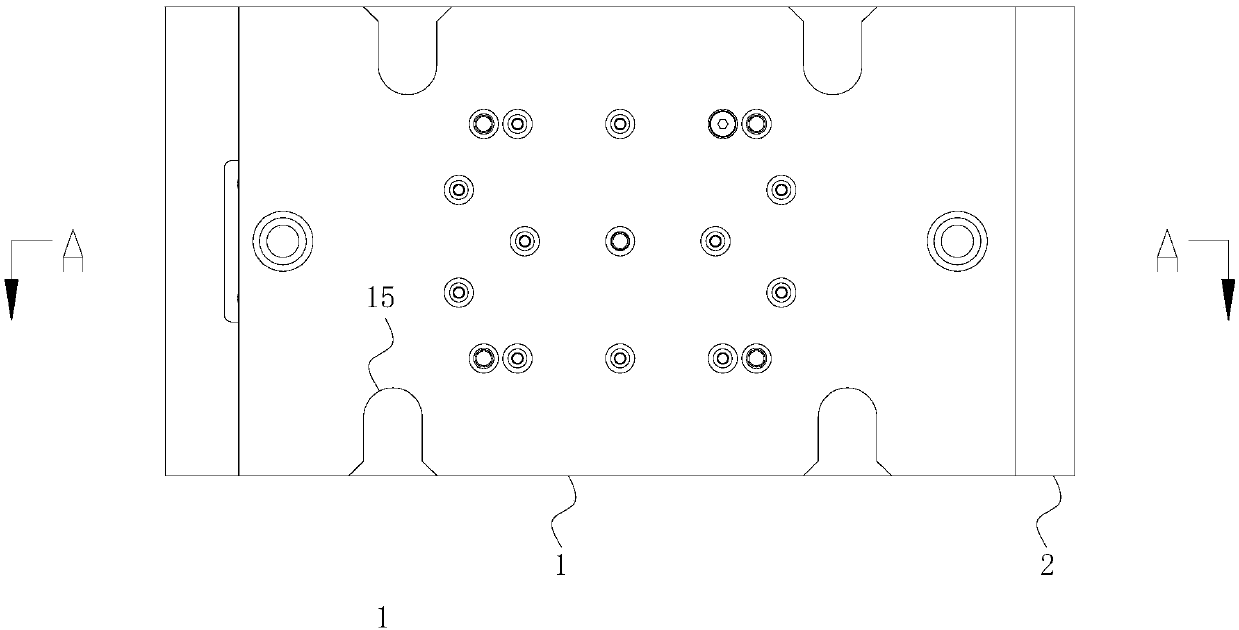

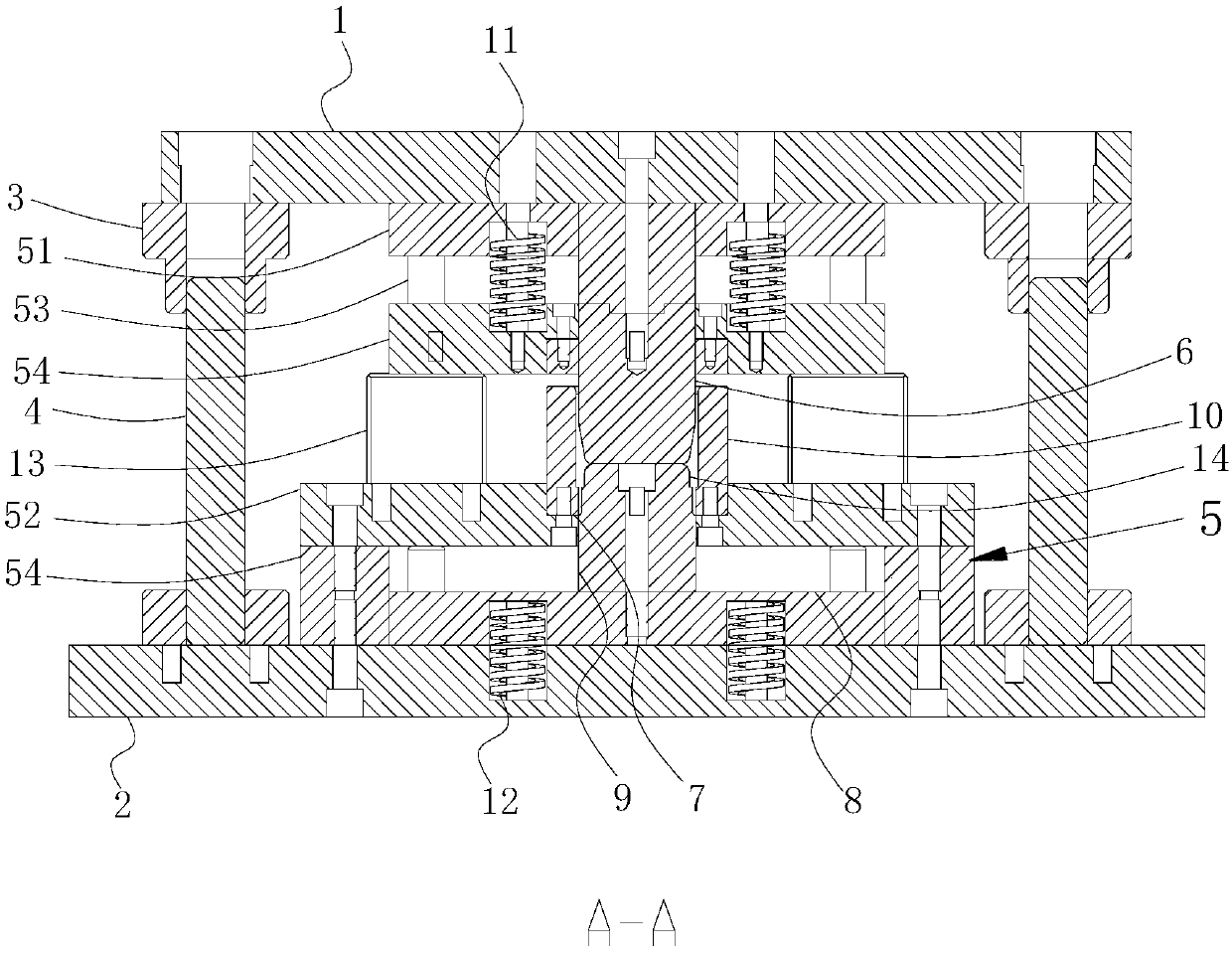

[0034] Embodiment: a kind of mold that is used for pipe fitting flaring, as figure 1 As shown, it includes an upper formwork 1 and a lower formwork 2 that can be close to each other. The upper formwork 1 is symmetrically provided with a guide sleeve 3 along the vertical direction, and a first guide post 4 is slidably connected in the guide sleeve 3. The templates 2 are connected through the first guide pillars 4 . The upper template (1) is evenly distributed around the entire upper template 1 along the axial direction of the stamping head 6, and the number is not less than four. Place the sling for the crane to facilitate the installation and transportation of the mold. A mold body 5 for forming is provided between the upper template 1 and the lower template 2. The mold body 5 includes a punch 51 and a die 52 that are matched with each other. The punch 51 is fixed on the upper template 1, and the die 52 is fixed on the lower die. Template 2 on.

[0035] Such as figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com