Filtering tool for low-pressure casting

A low-pressure casting and tooling technology, applied in the field of casting auxiliary equipment, can solve problems affecting the quality of castings, slag inclusions, etc., and achieve the effects of improving casting quality, simple structure, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

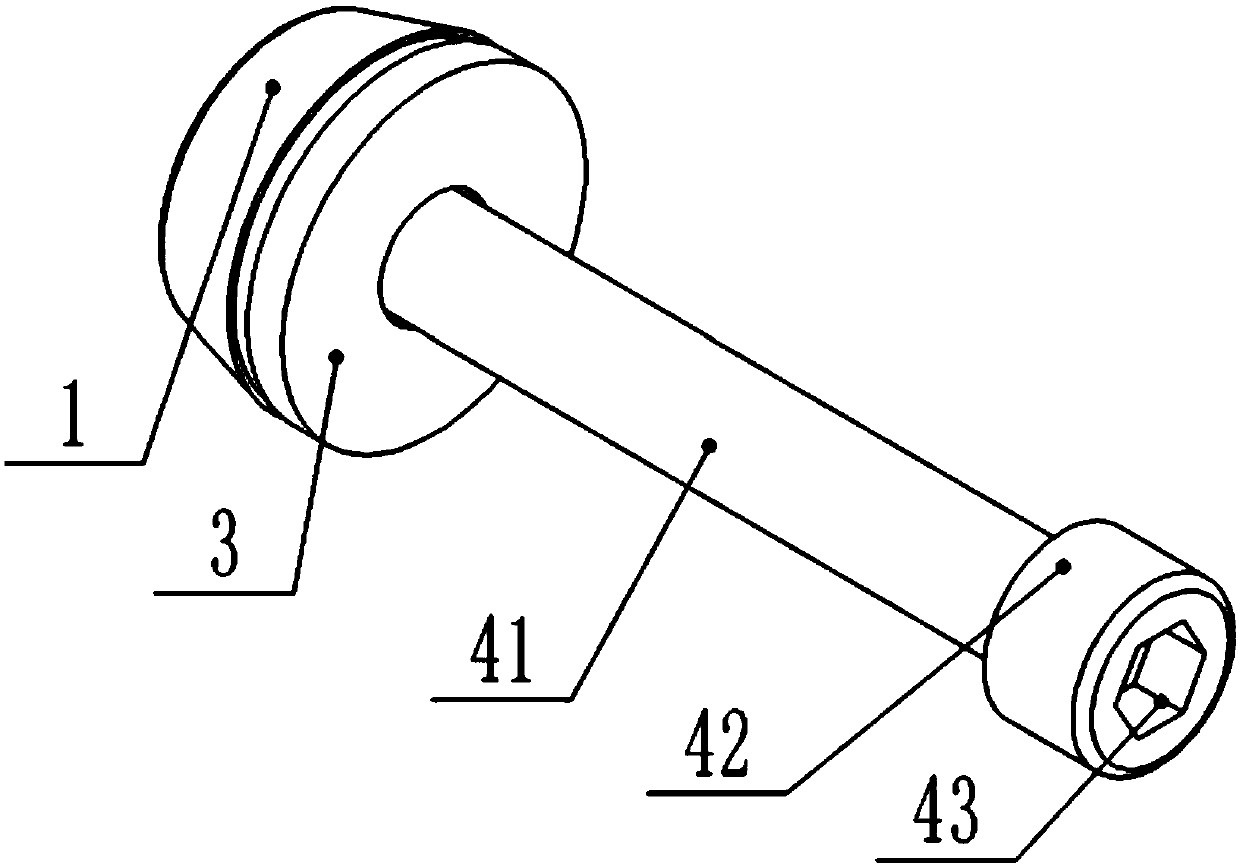

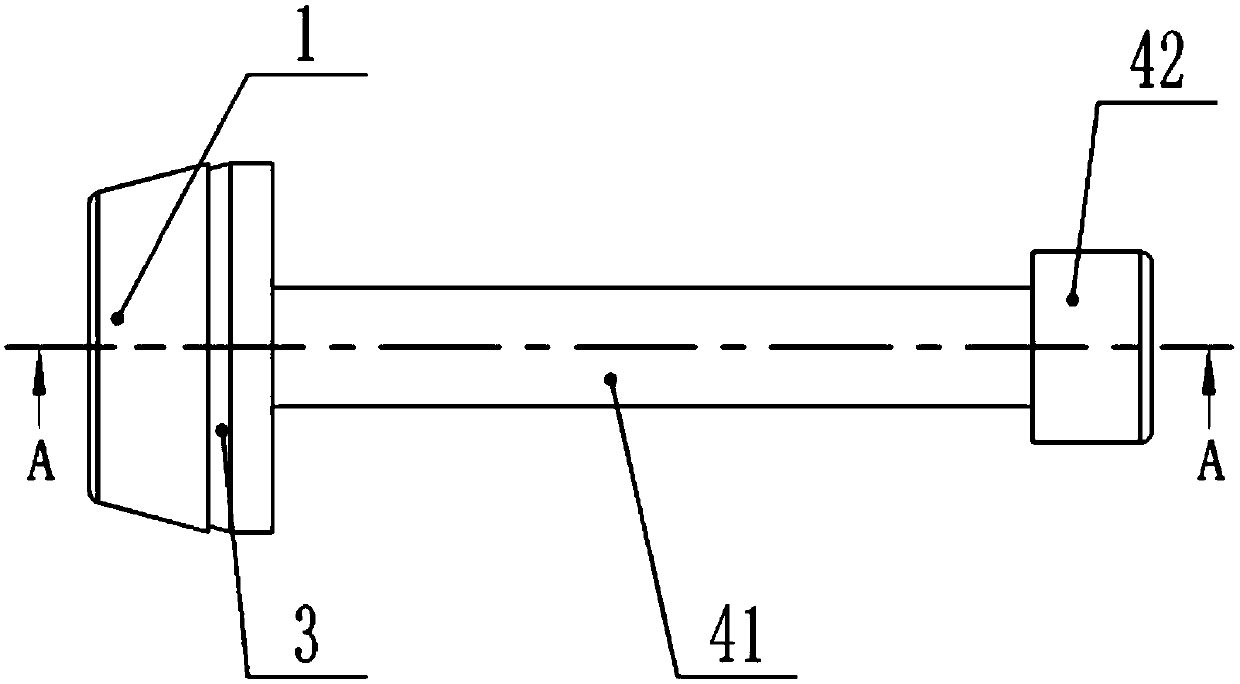

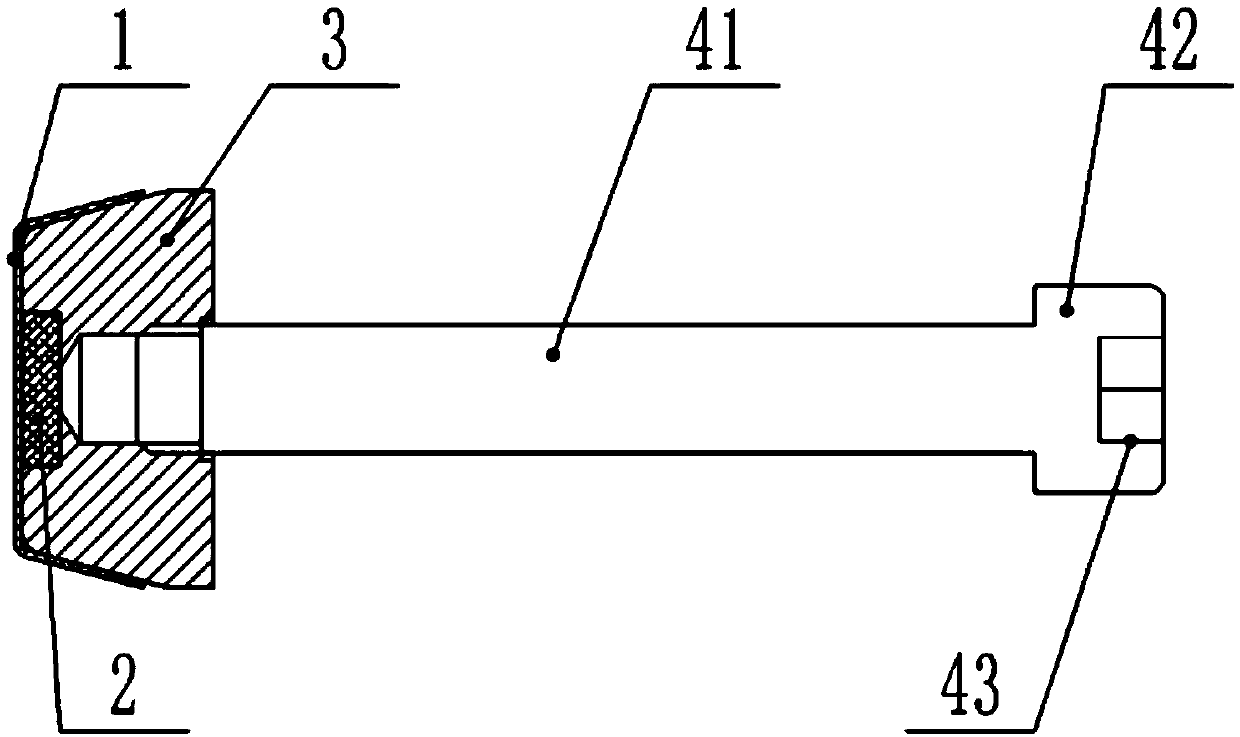

[0032] A filter tool for low-pressure casting, comprising a barbed wire 1 and a mesh cone main body 3, the surface of the barbed wire 1 is galvanized, the mesh number of the barbed wire 1 is 8 mesh, and the mesh diameter is 0.5mm. Barbed wire 1 is arranged on the outside of described net cone main body 3, and described net cone main body 3 is the conical structure setting that one end is narrow and one end is wide, and described net cone main body 3 is compatible with external sprue, and described net cone main body 3 The narrower end is coaxially provided with a magnet installation hole 31, and a high-temperature magnet 2 is arranged in the magnet installation hole 31. The cross section of the high-temperature magnet 2 is circularly arranged, and the diameter of the high-temperature magnet 2 is 18 mm. The thickness of the magnet 2 is 6 mm, the side wall of the high temperature magnet 2 is attached to the inner wall of the magnet installation hole 31, and the barbed wire 1 is a...

Embodiment 2

[0034] A filter tool for low-pressure casting, comprising a barbed wire 1 and a mesh cone main body 3, the surface of the barbed wire 1 is galvanized, the mesh number of the barbed wire 1 is 8 mesh, and the mesh diameter is 0.5mm. Barbed wire 1 is arranged on the outside of described net cone main body 3, and described net cone main body 3 is the conical structure setting that one end is narrow and one end is wide, and described net cone main body 3 is compatible with external sprue, and described net cone main body 3 The narrower end is coaxially provided with a magnet installation hole 31, and a high-temperature magnet 2 is arranged in the magnet installation hole 31. The cross section of the high-temperature magnet 2 is circularly arranged, and the diameter of the high-temperature magnet 2 is 18 mm. The thickness of the magnet 2 is 6 mm, the side wall of the high temperature magnet 2 is attached to the inner wall of the magnet installation hole 31, and the barbed wire 1 is a...

Embodiment 3

[0036] A filter tool for low-pressure casting, comprising a barbed wire 1 and a mesh cone main body 3, the surface of the barbed wire 1 is galvanized, the mesh number of the barbed wire 1 is 8 mesh, and the mesh diameter is 0.5mm. Barbed wire 1 is arranged on the outside of described net cone main body 3, and described net cone main body 3 is the conical structure setting that one end is narrow and one end is wide, and described net cone main body 3 is compatible with external sprue, and described net cone main body 3 The narrower end is coaxially provided with a magnet installation hole 31, and a high-temperature magnet 2 is arranged in the magnet installation hole 31. The cross section of the high-temperature magnet 2 is circularly arranged, and the diameter of the high-temperature magnet 2 is 18 mm. The thickness of the magnet 2 is 6 mm, the side wall of the high temperature magnet 2 is attached to the inner wall of the magnet installation hole 31, and the barbed wire 1 is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com