Auxiliary operating platform for assembling butterfly valve with large specification

An auxiliary operation and large-scale technology, applied in the direction of workbench, workpiece clamping device, manufacturing tools, etc., can solve the problems of frequent operator movements, product bumps, scratches, high consumption, etc., to achieve adjustment and cleaning time saving Labor-saving, neat and thorough, overcoming the effect of frequent movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

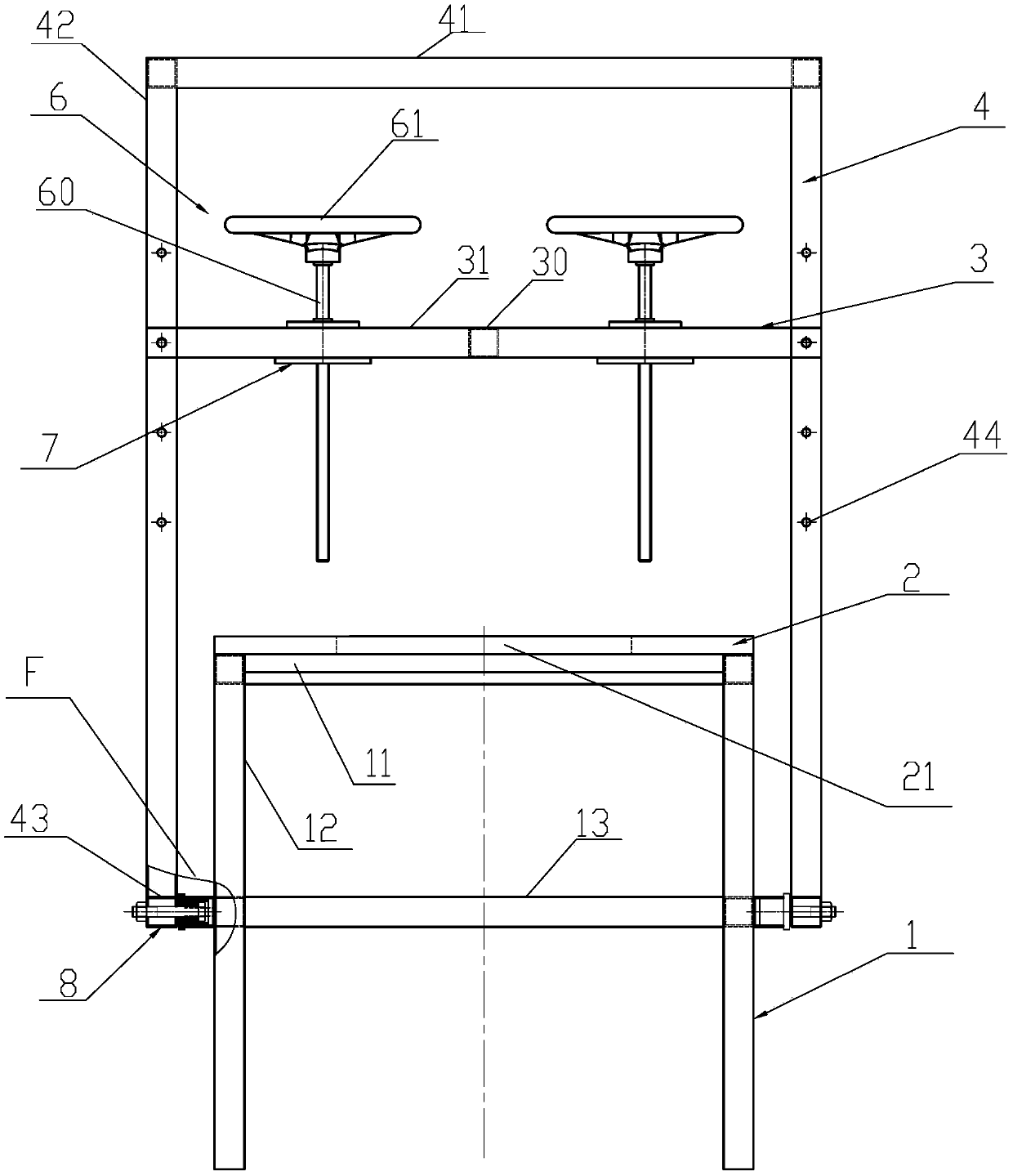

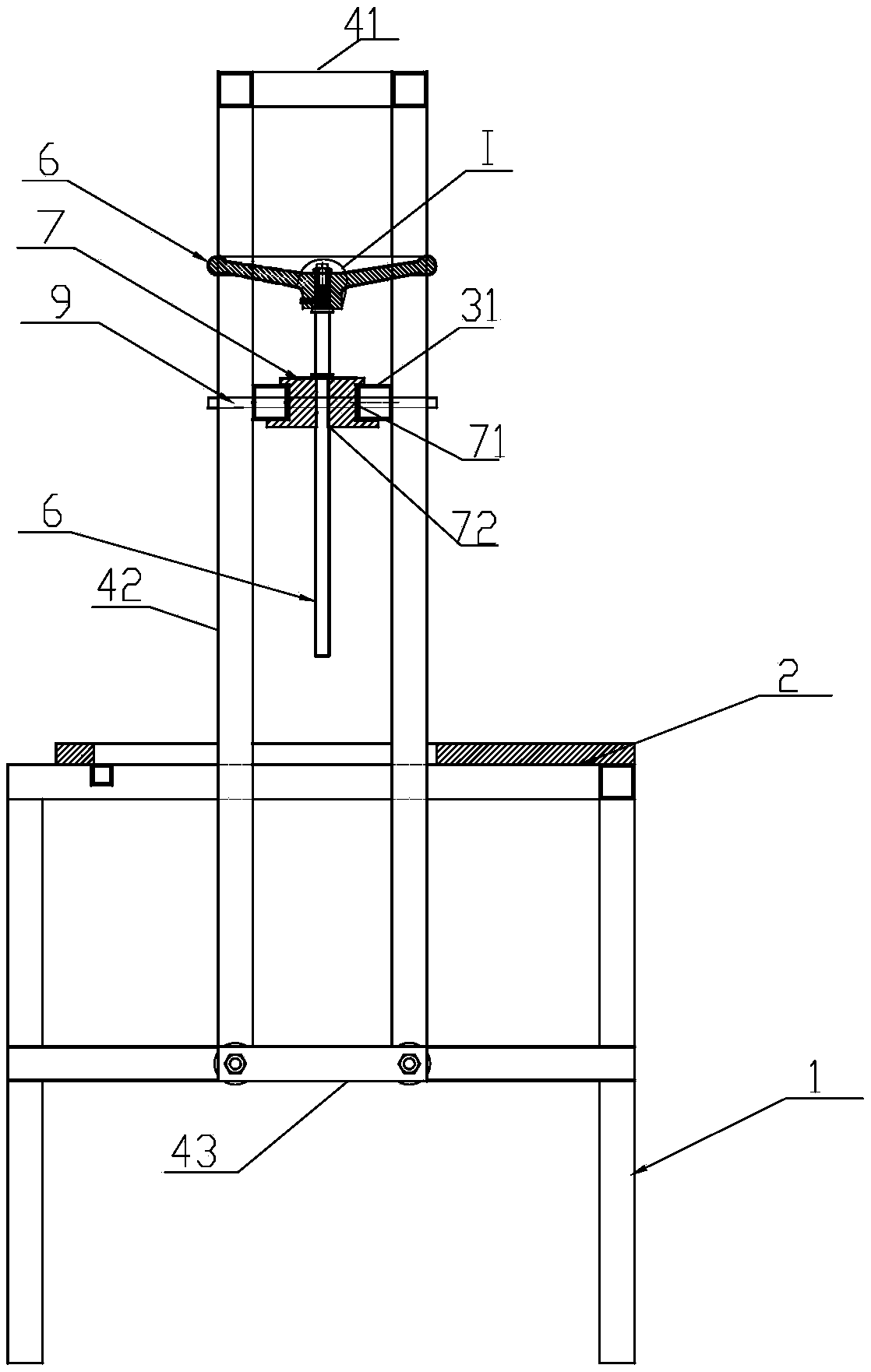

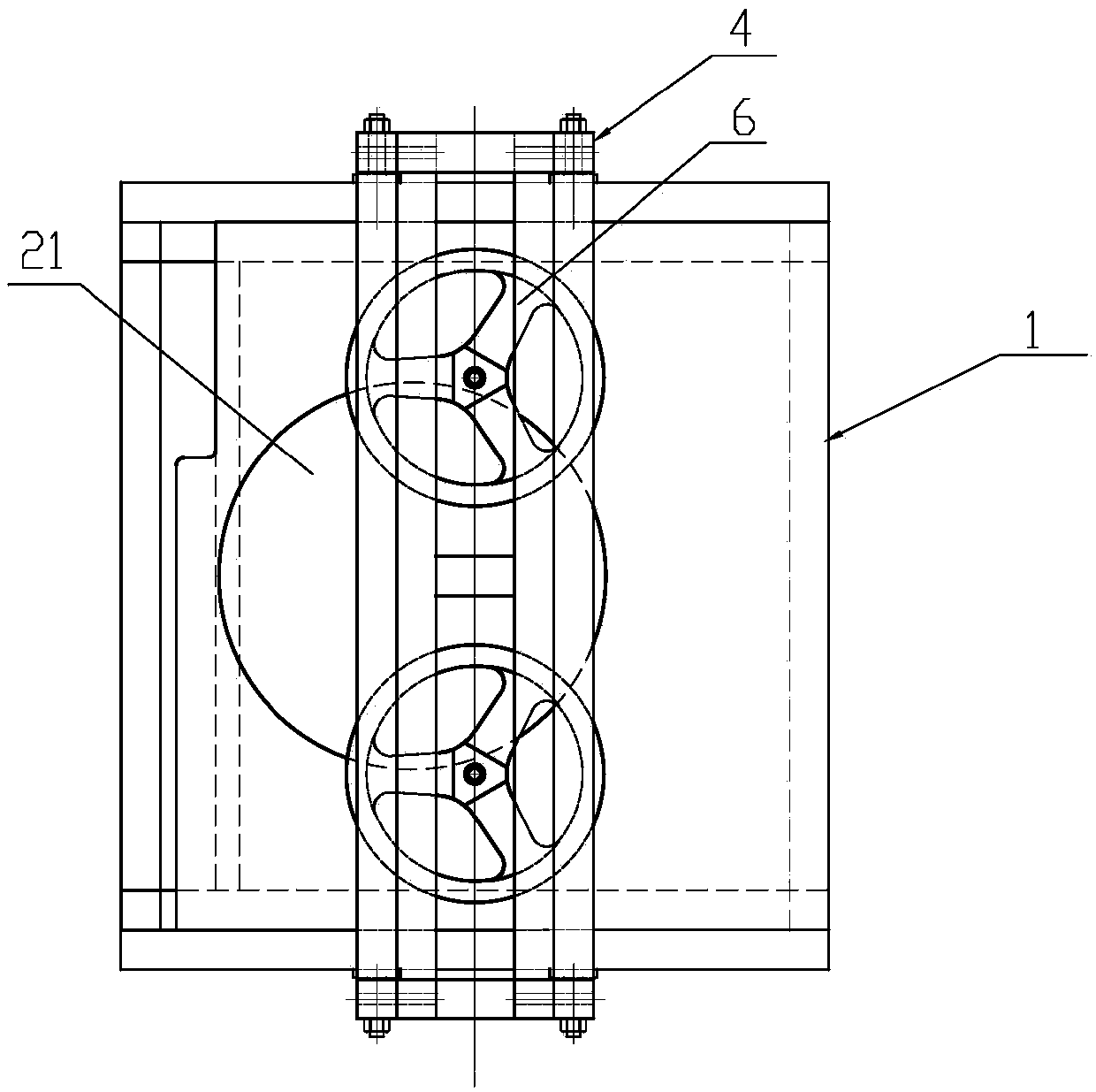

[0026] Figure 1 to Figure 7 It shows an auxiliary operating platform for large-scale butterfly valve assembly and its components, which is characterized in that it mainly includes a lower bracket 1, an upper bracket 4, a horizontal frame 3, a screw with a hand wheel 6, a plug pin 9 and a roller mechanism 8. The lower support 1 is composed of a square table frame 11, four legs 12 connected to the four corners of the table frame and cross braces 13 connected between adjacent legs 12, and a butterfly valve carrier plate 2 is placed on the table frame 11. A round hole 21 corresponding to the size of the butterfly valve plate to be assembled and adjusted is provided on the butterfly valve carrying plate 2 . In practical application, the above-mentioned auxiliary operation platform should be equipped with butterfly valve bearing plates of various specifications to meet the needs of butterfly valves of different specifications to be assembled and adjusted.

[0027] Above the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com