Servo control system of 500 ton four-column hydraulic press

A servo control system and hydraulic press technology, which is applied to stamping machines, presses, manufacturing tools, etc., can solve the problems of low efficiency of presses, raising the pressure head, and low repeat positioning accuracy of presses, so as to improve control accuracy and efficiency, The effect of improving the level of automation and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

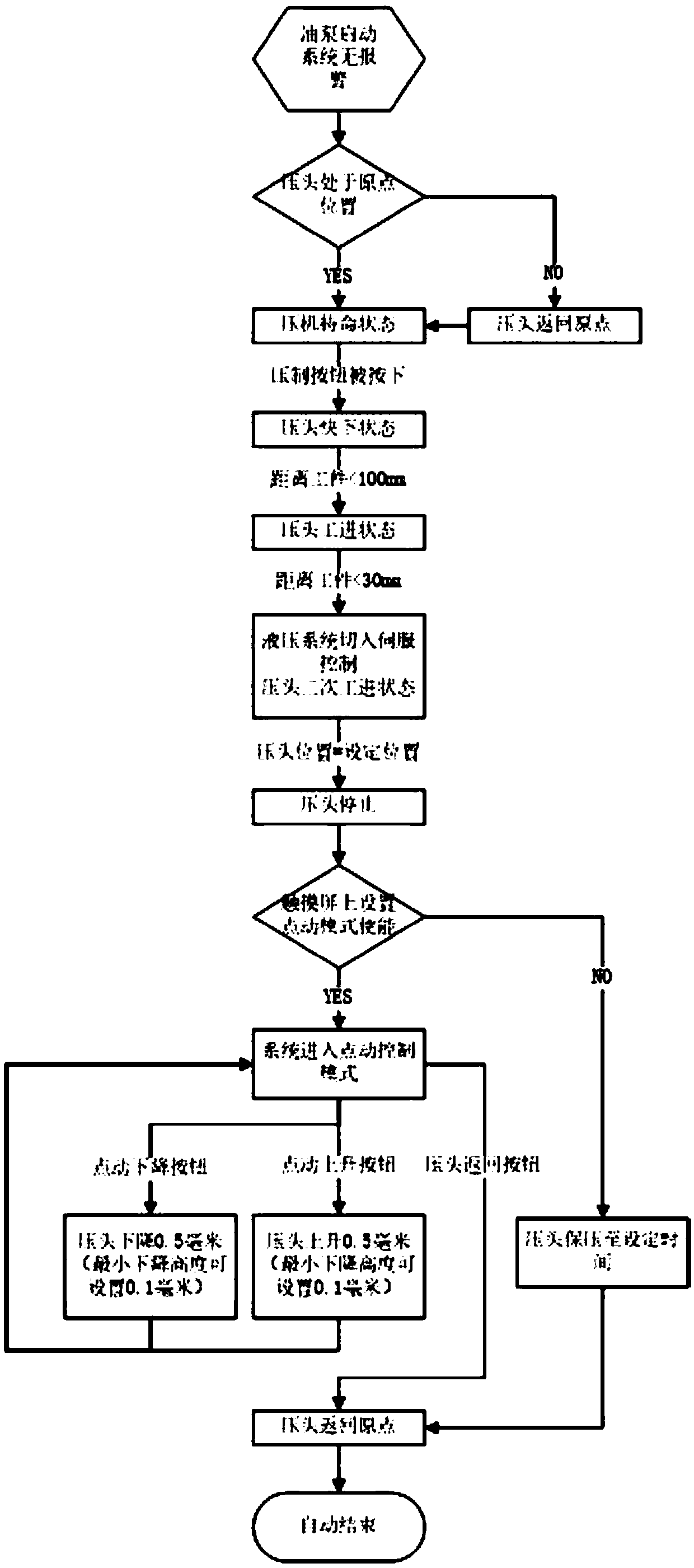

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

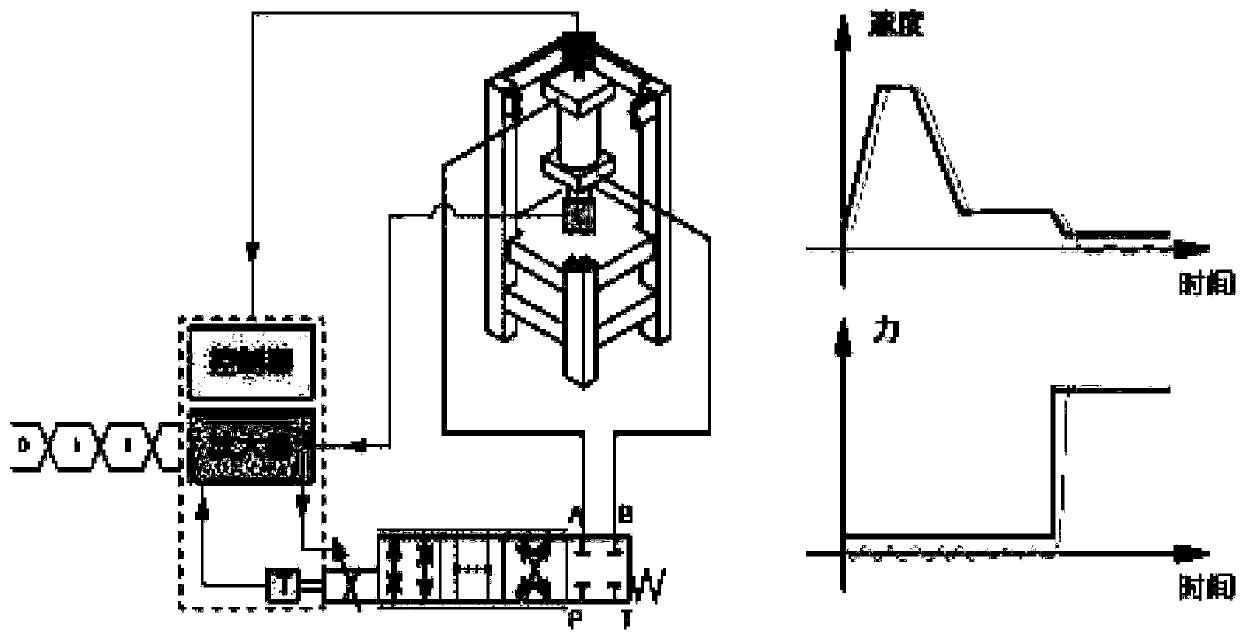

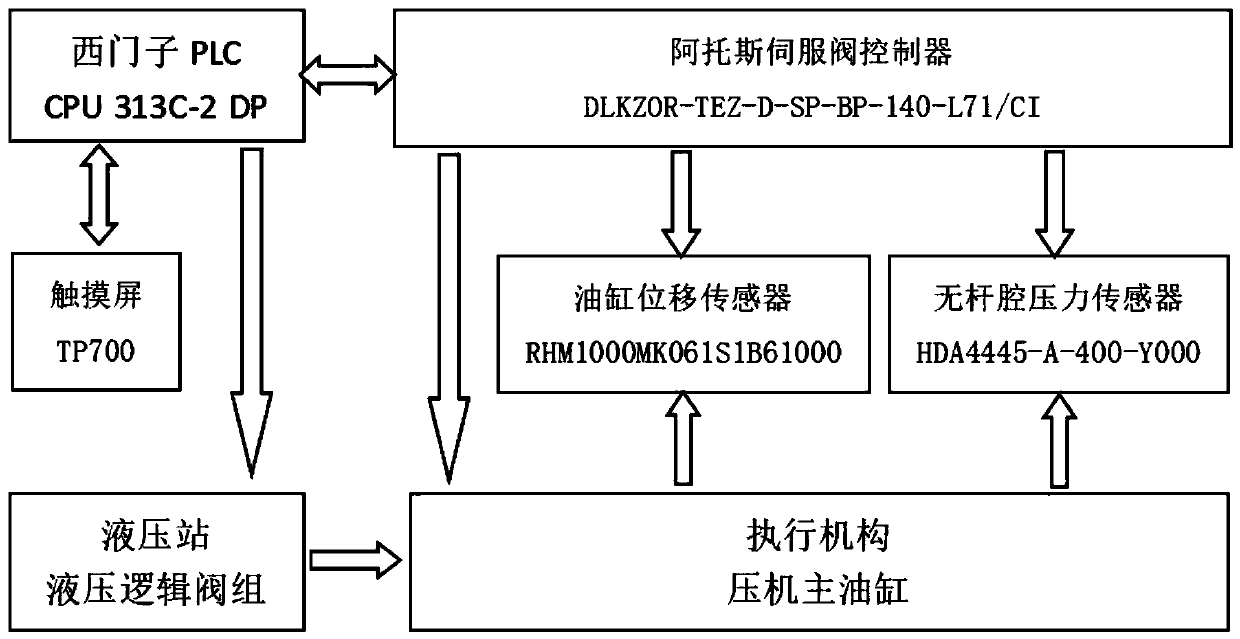

[0020] The hardware part of the present invention is composed of Siemens S7-300 series programmable logic controller (Programmable Logic Controller, PLC) and TP700 touch screen. The actuator adopts a set of Atos DLKZOR-T servo valve to control the low-friction oil cylinder, and the oil cylinder is built with American MTS high-precision Displacement sensor, in which a high-precision pressure sensor is built in the main oil cylinder, which is used to detect the pressure of the rodless chamber of the oil cylinder and indirectly measure the pressure of the press;

[0021] The invention selects the communication mode to control the Atos LKZOR-T servo valve, which is more accurate than the traditional analog control mode, and the data has strong anti-interference ability;

[0022] This control system is mainly carried out around the Atos DLKZOR-T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com