An ice skating tool

A tool and ice surface technology, applied in the field of ice gliding tools, can solve the problems of difficult large-scale promotion, poor power output and durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

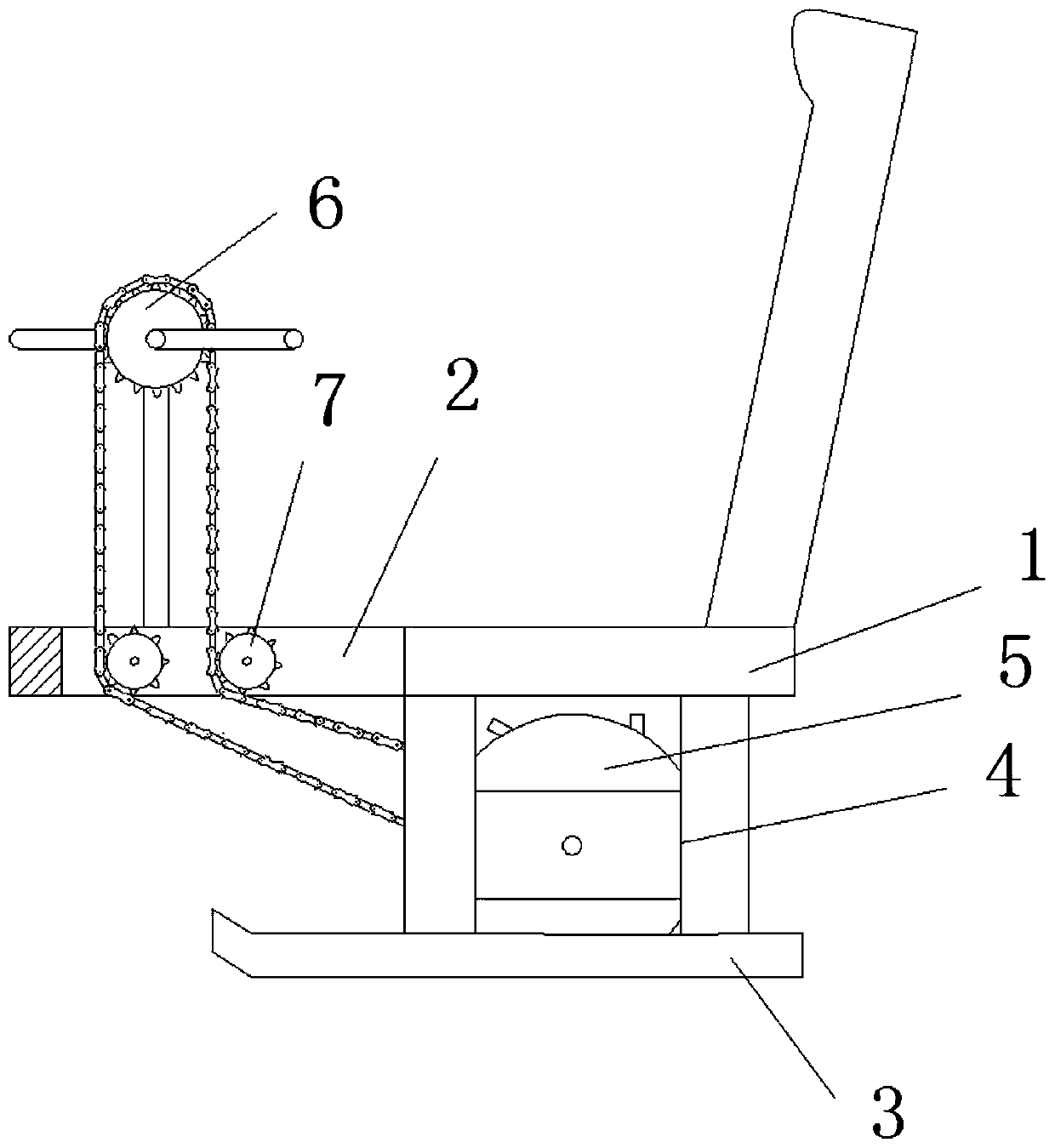

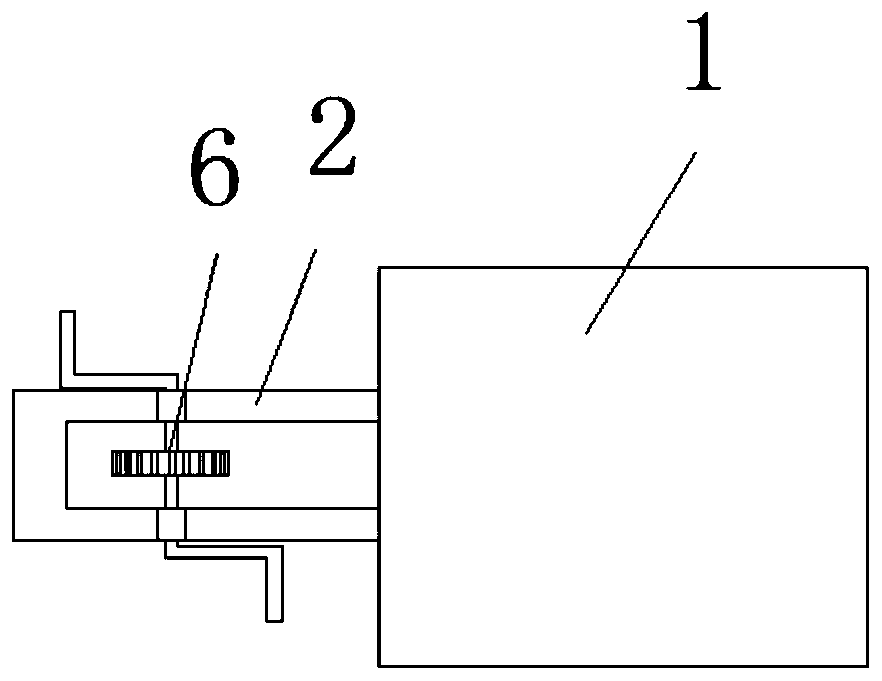

[0052] like figure 1 , 2 , 3 and 5, a kind of ice gliding tool disclosed in this embodiment includes a seat plate 1, a U-shaped bar 2, a slide plate 3, an H-shaped connecting frame 4, a pushing device 5, a hand crank 6 and a variable To the gear 7; one end of the upper end surface of the seat plate 1 is provided with a backrest, the other end side wall of the seat plate 1 is provided with a U-shaped rod 2, and the lower end of the seat plate 1 is provided with two slide plates 3 in parallel and symmetrically, The slide plate 3 is connected to the lower end surface of the seat plate 1 through an H-shaped connecting frame 4, and a pushing device 5 is arranged to rotate between the two H-shaped connecting frames 4, and the manual tooth plate 6 is arranged on the U-shaped bar 2 through a strut. At the upper end, the manual crankset 6 is connected with the pusher 5 through a chain, and the chain passes through the U-shaped bar 2 and cooperates with the reversing gear 7, and the ma...

specific Embodiment approach 2

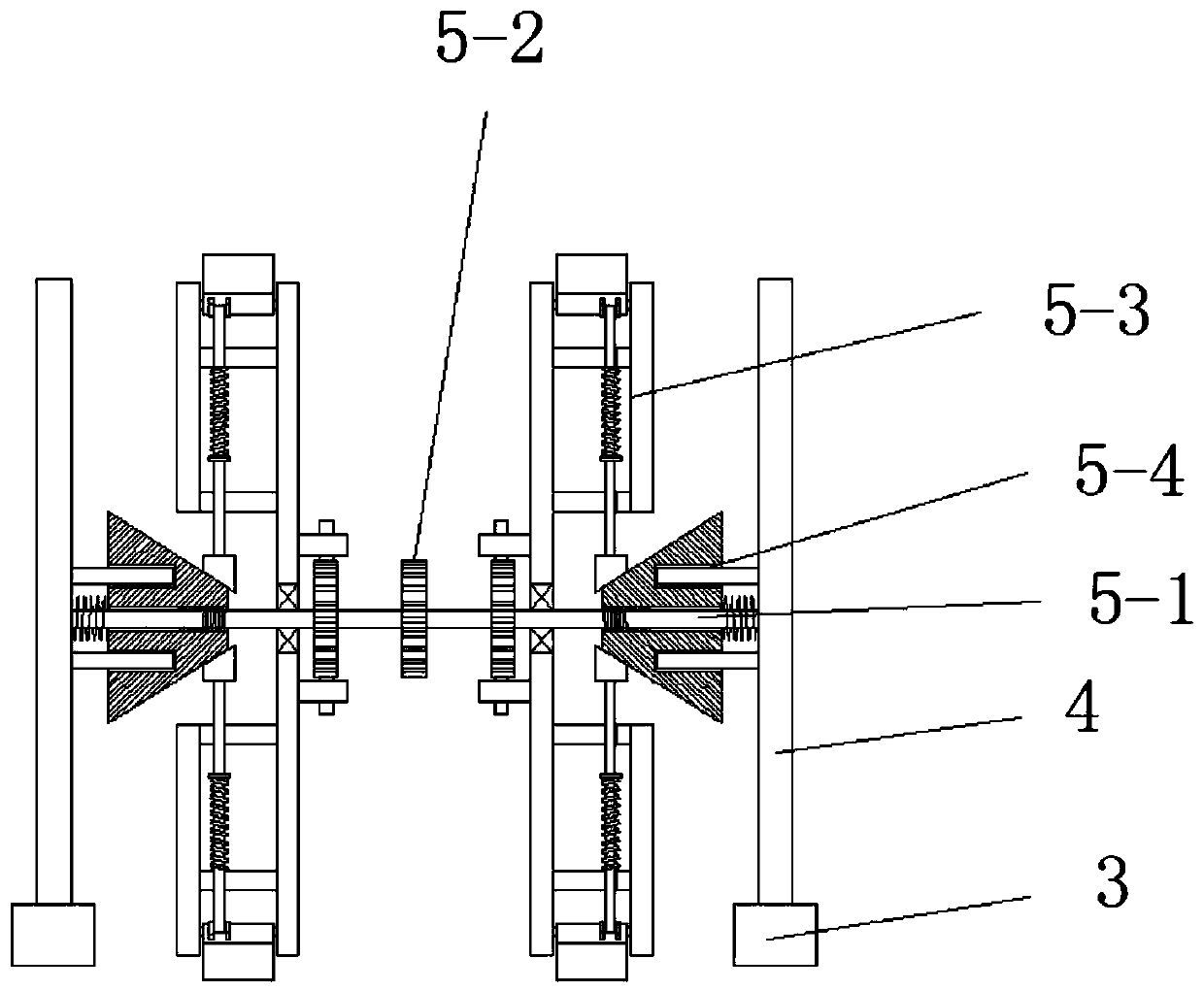

[0060] combine image 3 , 4 , 5, 6, 7 and 8, this embodiment is based on the specific embodiment one, the difference is that the rotating device 5-3 includes a disc 5-3-1, a ratchet 5-3-2, Limiting piece 5-3-3, cylinder 5-3-4, connecting plate 5-3-5, annular disc 5-3-6, transmission rod 5-3-7, trapezoidal limiting block 5-3-8 , the first pressure spring 5-3-9 and the friction member 5-3-10; the disc 5-3-1 is set on the rotating shaft 5-1 through the bearing, and the ratchet 5-3-2 is set on the disc 5-3-1 Between the 3-1 and the rotating shaft 5-2, two limiters 5-3-3 are arranged symmetrically on the center of the inner wall of the disc 5-3-1, and the limiter 5-3-3 and the ratchet 5-3- 2, the outer wall of the disc 5-3-1 is connected with the annular disc 5-3-6 through the cylinder 5-3-4, a plurality of connecting plates 5-3-5 and the rod shaft, and the plurality of connecting plates 5-3-6 - The 3-5 ring array is on the outer wall of the disc 5-3-1, the connecting plate 5-3-...

specific Embodiment approach 3

[0064] combine image 3 , 5 As shown in and 9, this embodiment is based on the first embodiment, the difference is that the positioning device 5-4 includes a conical platform 5-4-1, a limit rod 5-4-4 and a return spring 5-4-5; the center of the conical table 5-4-1 is provided with a through cavity 5-4-2, the through cavity 5-4-2 is provided with internal threads, and the two ends of the through cavity 5-4-2 are symmetrically opened Limit cavity 5-4-3, one end of the limit rod 5-4-4 arranged in parallel and symmetrically is arranged on the H-shaped connecting frame 4, and the other end is set in the limit cavity 5-4-3, and the conical platform 5 -The outer side wall of -4-1 links to each other with the H-shaped connecting frame 4 through the return spring 5-4-5 on the rotating shaft 5-1, the inclined side wall of the conical platform 5-4-1 and the trapezoidal limit block 5-3- 8 against each other;

[0065] When the internal thread in the through cavity 5-4-2 of the conical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com