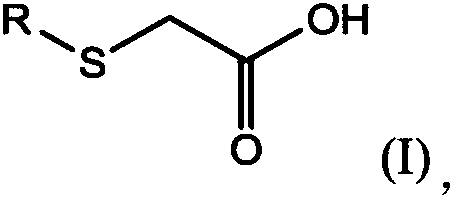

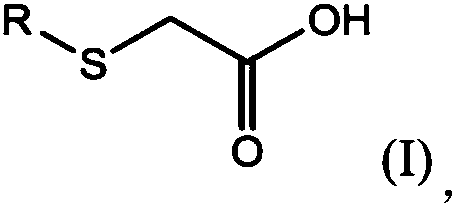

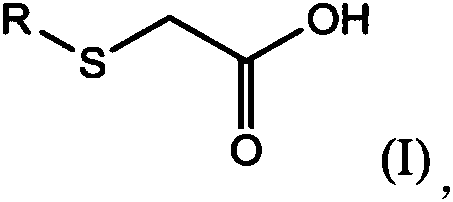

Stable electroless copper plating compositions and methods for electroless plating copper on substrates

A technology of electroless copper plating and composition, applied in the field of electroless copper plating composition and electroless copper plating on a substrate, to achieve the effect of reducing consumption and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] Electroless Copper Compositions of the Invention The following aqueous alkaline electroless copper compositions were prepared with the components and amounts disclosed in Table 1 below.

[0061] Table 1

[0062]

[0063]

[0064] The pH of the aqueous alkaline electroless copper composition at room temperature = 12.7 as measured using a conventional pH meter available from Fisher Scientific.

example 2

[0066] Backlight experiment using aqueous alkaline electroless copper plating composition of the present invention

[0067] Four (4) each of six (6) different FR / 4 glass epoxy boards with multiple through holes are available: TUC-662, SY-1141, IT-180, 370HR, EM825, and NPGN. Boards are copper-clad four-layer or eight-layer boards. TUC-662 was obtained from Taiwan Union Technology, and SY-1141 was obtained from Shengyi. IT-180 was obtained from ITEQ Corp., NPGN was obtained from NanYa, 370HR was obtained from Isola, and EM825 was obtained from Elite Materials Corporation. Plate T g Values range from 140°C to 180°C. Each plate is 5 cm x 12 cm.

[0068] The through hole processing of each board is as follows:

[0069] 1. CIRCUPOSIT for through-holes of each board TM Hole Prep 3303 solution was decontaminated at 80°C for 7 minutes;

[0070] 2. Then rinse the through holes of each board with flowing tap water for 4 minutes;

[0071] 3. Then place the vias with CIRCUPOSIT...

example 3

[0088] ICD Experiments Using the Aqueous Alkaline Electroless Copper Composition of the Invention Under Various MTOs

[0089] A plurality of six different copper-clad multilayer FR / 4 glass-epoxy boards with multiple vias were provided as in Example 2: TUC-662, SY-1141, IT-180, 370HR, EM825, and NPGN. The through hole processing of each board is as follows:

[0090] 1. Connect the through holes of each board with CIRCUPOSIT TM Hole Prep 3303 solution was decontaminated at 80°C for 7 minutes;

[0091] 2. Then rinse the through holes of each board with flowing tap water for 4 minutes;

[0092] 3. Then place the vias with CIRCUPOSIT TM MLB Promoter 3308 permanganate aqueous solution was treated at 80°C for 10 minutes;

[0093] 4. Then rinse the through hole with running tap water for 4 minutes;

[0094] 5. Then the through hole was treated with 3wt% sulfuric acid / 3wt% hydrogen peroxide neutralizer at room temperature for 2 minutes;

[0095] 6. Then rinse the through holes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com