Basement exterior wall construction method and structure

A basement external wall and construction method technology, applied in the direction of basic structure engineering, excavation, building components, etc., can solve the problems of external formwork cracking, affecting the removal of external formwork, etc., to improve waterproof strength, control harmful cracks, and avoid edge temperature The effect of gradient descent too fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

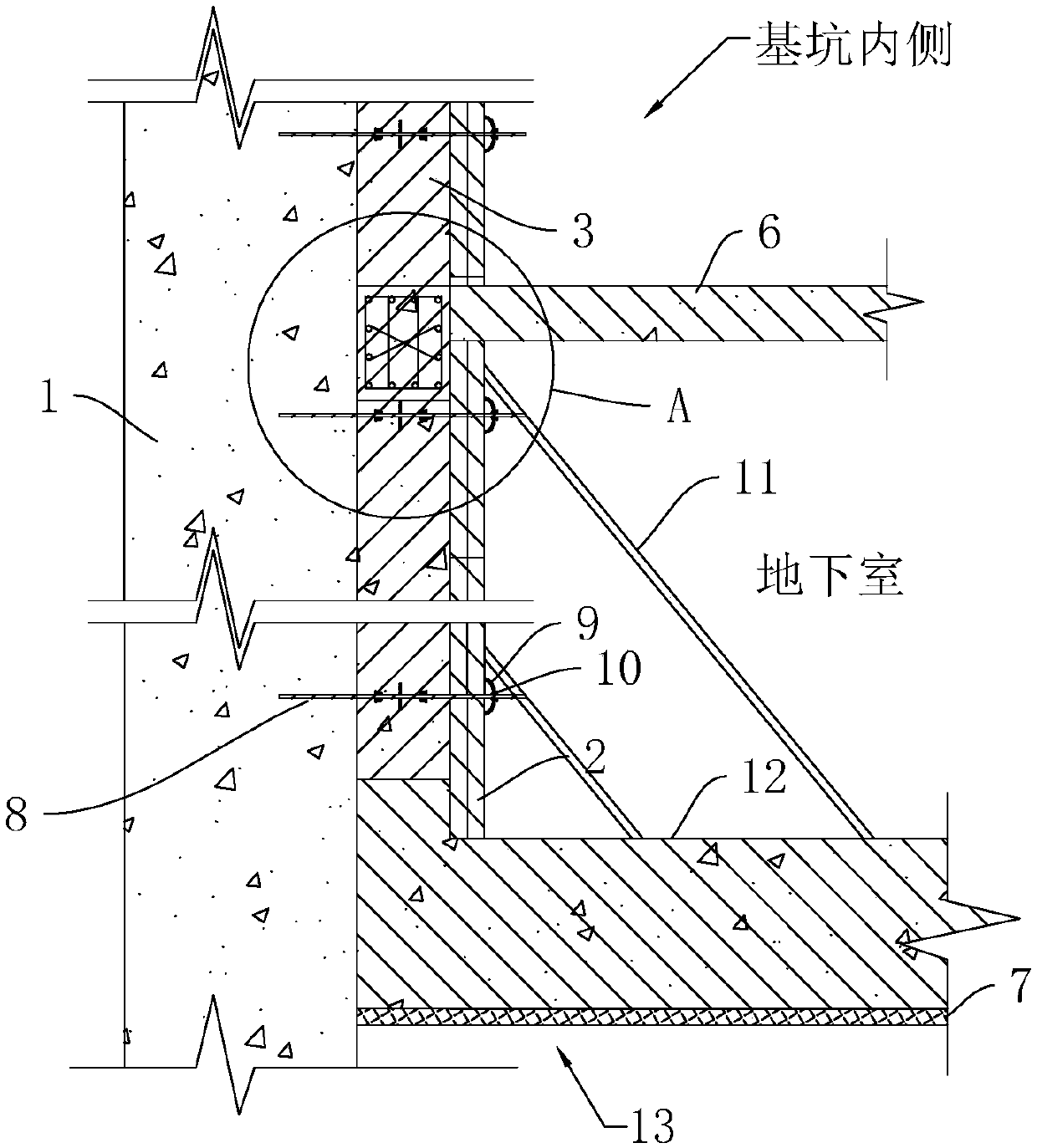

[0046] Embodiment 1: construction method of basement exterior wall, refer to figure 1 and figure 2 , including the following steps:

[0047] Step 1: laying flexible coiled material 7 and pouring basement floor 12: ramming plain soil at the bottom of the foundation pit to form a cushion 13, laying flexible coiled material 7 on the cushion 13, and pouring concrete on the flexible coiled material 7 to form a basement floor 12. The flexible membrane 7 is preferably a polymer self-adhesive waterproof membrane.

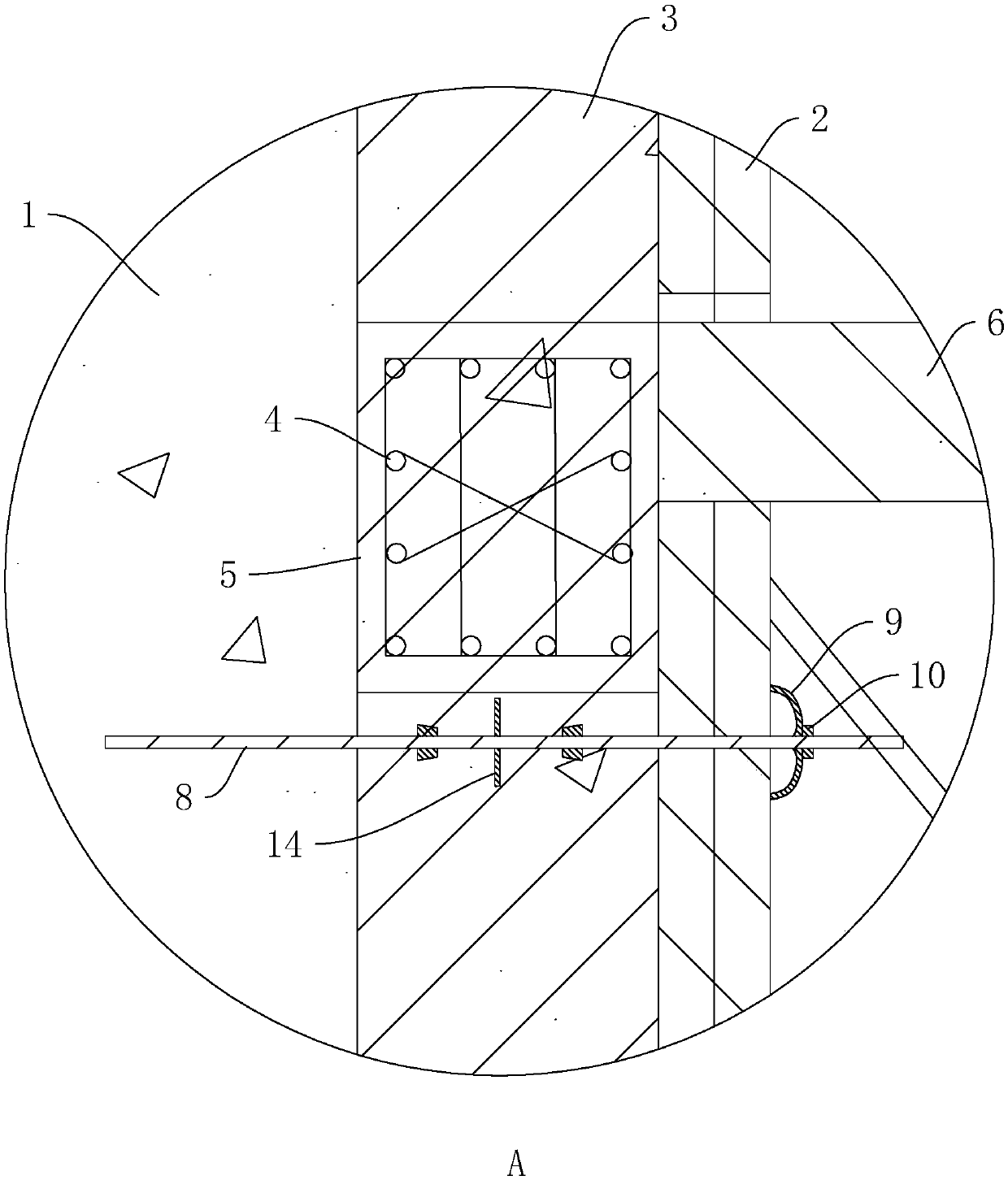

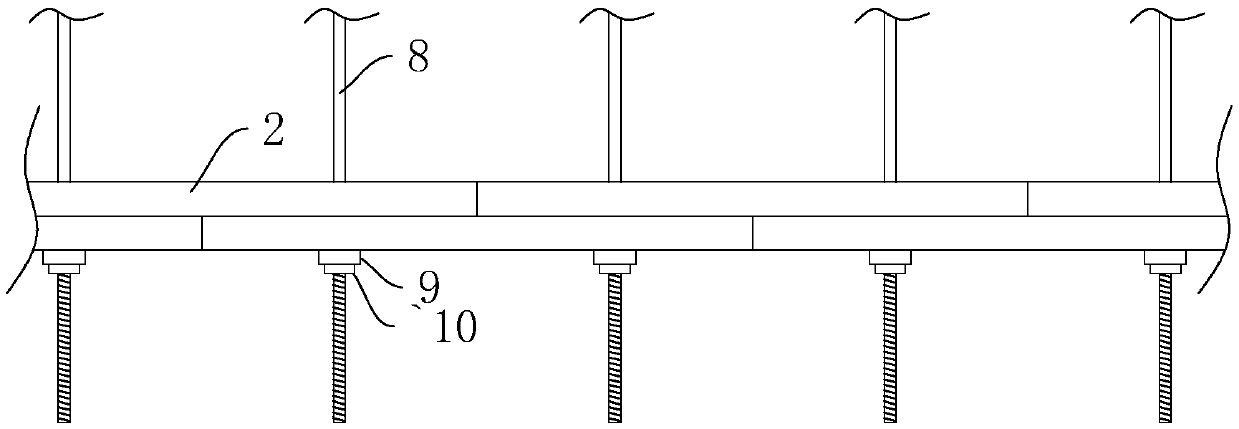

[0048] Step 2: Implant formwork reinforcement bars 8 into the underground diaphragm wall 1 in foundation pit support, one end of the formwork reinforcement bars 8 protrudes from the underground diaphragm wall 1, and a water stop 14 is provided where the reinforcement formwork protrudes from the underground diaphragm wall 1.

[0049] Step 3: The underground diaphragm wall 1 faces the inner side of the foundation pit and erects structural steel bars for forming the basemen...

Embodiment 2

[0064] Embodiment 2: Basement exterior wall structure, such as Figure 4 As shown, it is obtained according to the construction method of the basement exterior wall of embodiment 1, including the basement exterior wall 3, the hidden beam 5 and the basement floor 12, wherein:

[0065] The basement exterior wall 3 is formed by erecting an inner formwork 2 on the side of the underground diaphragm wall 1 facing the inside of the foundation pit and pouring concrete between the underground diaphragm wall 1 and the inner formwork 2 .

[0066] The hidden beam 5 is formed by laying crossbeam steel bars 4 along the horizontal direction in the basement exterior wall 3 .

[0067] The basement floor 12 is formed by laying the flexible coiled material 7 at the bottom of the foundation pit and pouring concrete on the flexible coiled material 7 .

[0068] Beneficial effects: using the underground diaphragm wall 1 in foundation pit support as a part of the side wall of the basement, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com