Unpowered ventilation device and tunnel

A technology of power ventilation and ventilation pipes, which is applied in the direction of pump devices, mine/tunnel ventilation, engines, etc., and can solve the problems of unfavorable health, poor economy, and impact on air quality of passing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

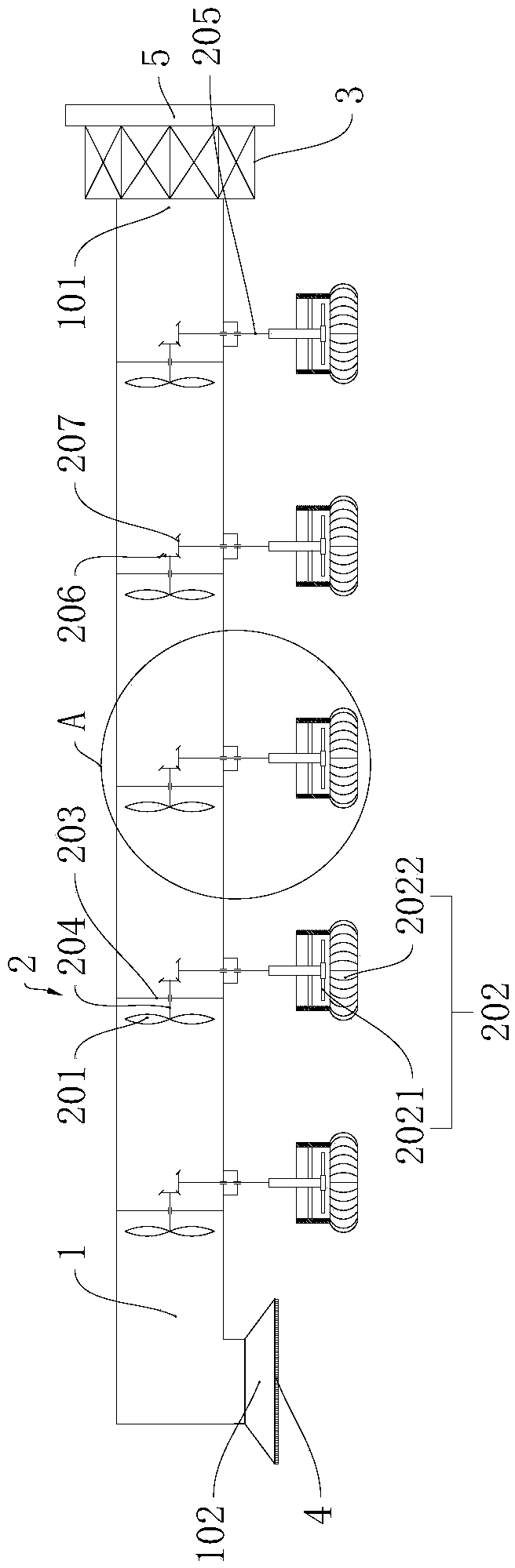

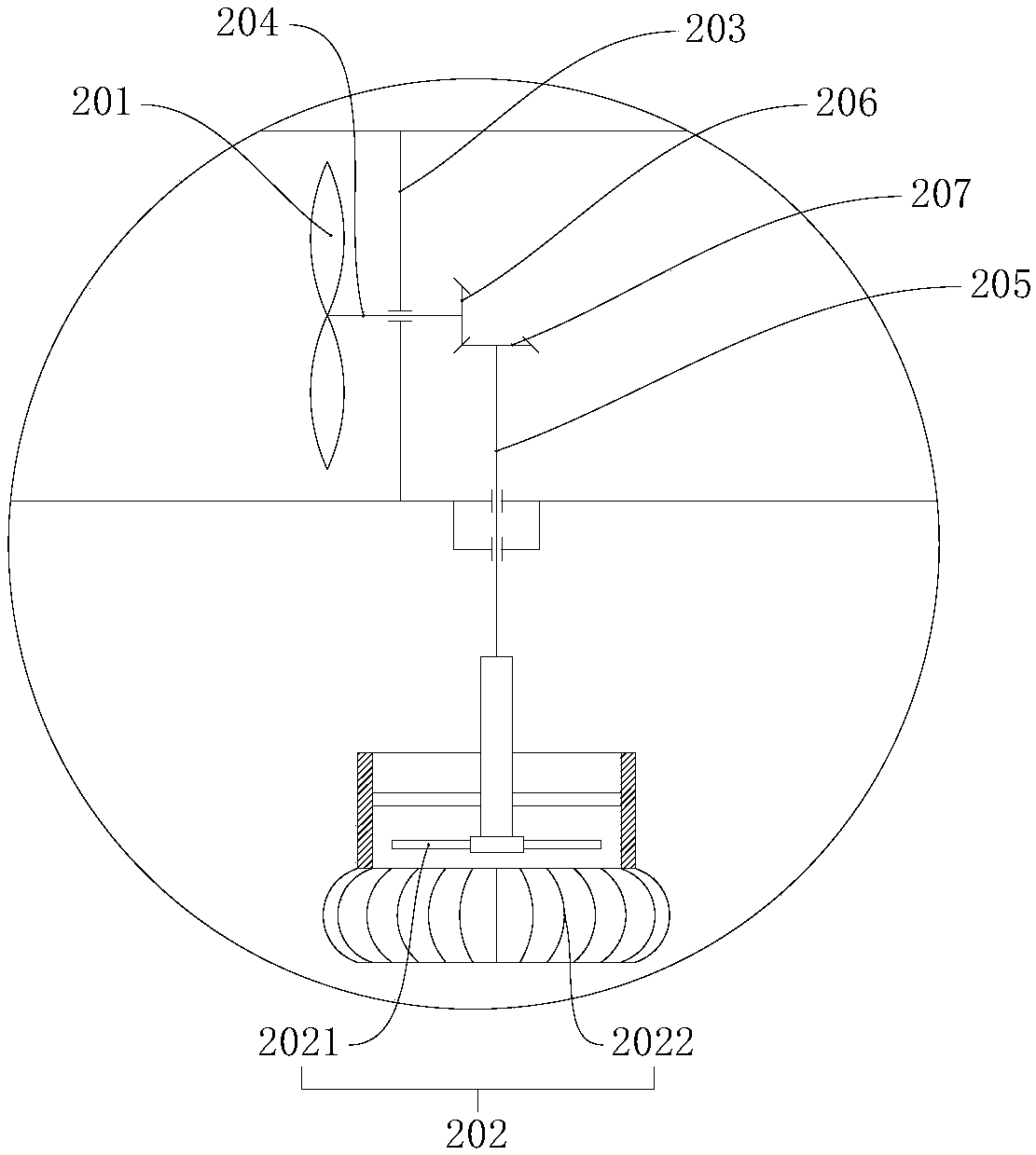

[0042] see image 3 The tunnel provided in this embodiment includes a tunnel body 6 and the aforementioned non-powered ventilation device, the ventilation duct 1 is arranged along the extension direction of the tunnel body 6, the blower assembly 2 is located outside the tunnel body 6, and the second tuyere 102 is located in the tunnel body 6 , the unpowered wind balloon 202 is located in the tunnel body 6 , and the rotation axis of the unpowered wind balloon 202 is perpendicular to the extending direction of the tunnel body 6 .

[0043] Because the tunnel body 6 is generally a long and narrow space, the closer to the exit of the tunnel body 6 in the long and narrow space of the tunnel body 6, the more the gas exchanges with the gas outside the tunnel body 6, and the farther away from the position of the exit of the tunnel body 6, the more The less the gas exchanges with the gas outside the tunnel body 6; the worse the gas quality is at the position farther away from the outlet...

Embodiment 2

[0049] see image 3 The tunnel provided by this embodiment includes a tunnel body 6 and the aforementioned unpowered ventilation device, each ventilation duct 1 is arranged along the extension direction of the tunnel body 6, and each ventilation duct 1 communicates with the inner cavity of the tunnel body 6 main body and the tunnel body 6 The external environment of the main body; each unpowered wind ball 202 is located in the tunnel body 6, and the rotation axis of each unpowered wind ball 202 is perpendicular to the extension direction of the tunnel body 6; Fan the wind in the direction of the tunnel body 6; in another part of the non-powered ventilation device, the rotating fan 201 fans the wind from the inside of the tunnel body 6 to the direction outside the tunnel body 6. Due to the use of the aforementioned unpowered ventilation device, under the action of the unpowered wind ball 202, the blower assembly 2 can transfer the kinetic energy of the airflow blowing on it alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com