Vertical type turbine bearing system

A turbine bearing and vertical technology, which is applied to non-variable pumps, components of pumping devices for elastic fluids, pump devices, etc., can solve problems such as complex structures, achieve short acceleration time, simplify structures, reduce The effect of small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

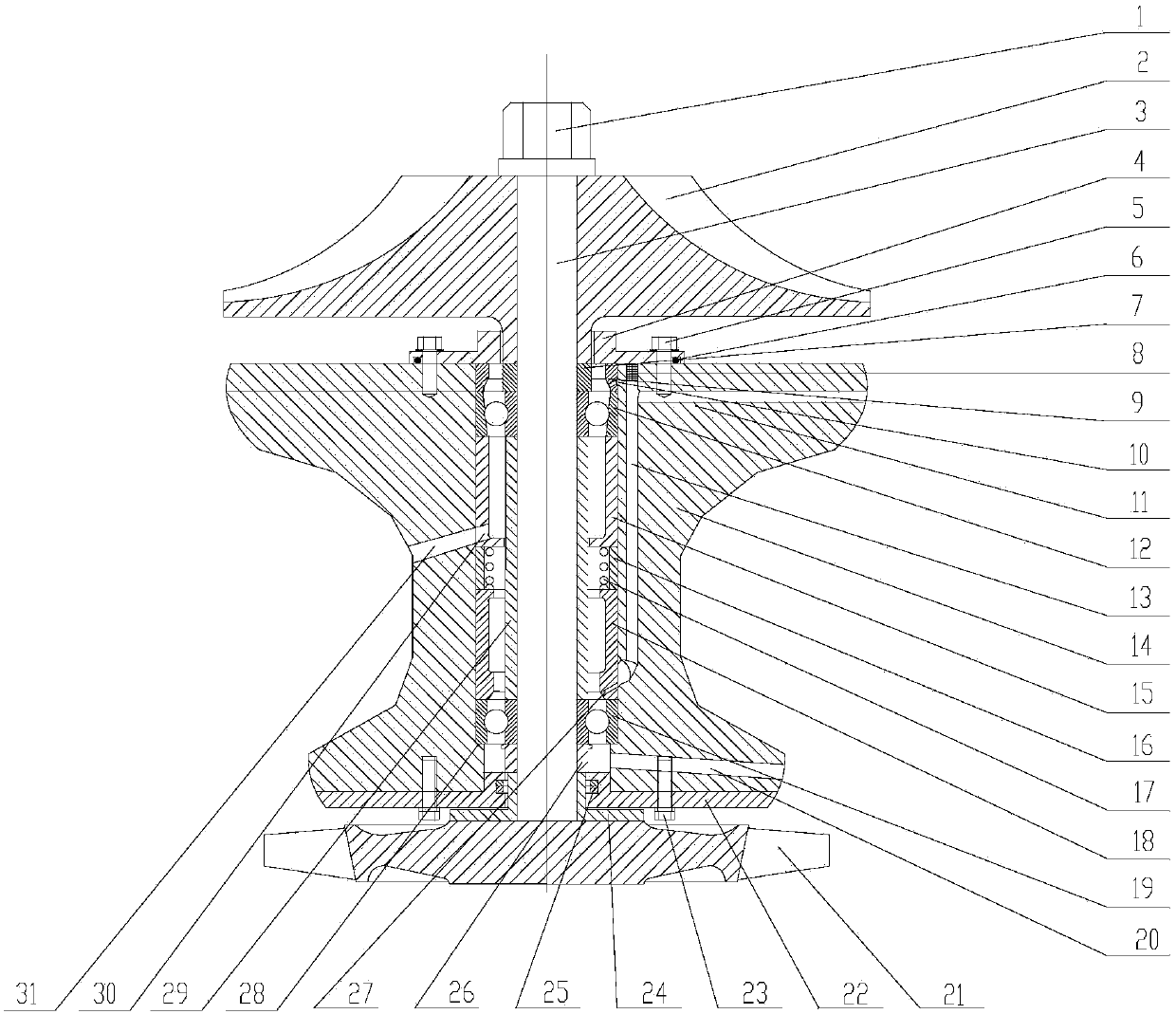

[0022] Such as figure 1 As shown, the embodiment of the present invention is a vertical turbine bearing system structure, including shaft 3, bearing body 14, upper spacer sleeve 7, upper nozzle sleeve 9, angular contact ball bearing 12, upper sleeve 15, spring sleeve 16. Spring 17, lower sleeve 18, deep groove ball bearing 19, inner sleeve 29, oil throwing ring 26, lower spacer sleeve 24, etc.

[0023] The upper and lower ends of the bearing body 14 are respectively set in the middle of the shaft 3 through the angular contact ball bearing 12 and the deep groove ball bearing 19, and the compressor impeller 2 and the turbine 21 are installed on the upper and lower ends of the shaft 3 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com