Mine wheel edge reducer and installation method of eccentric shaft assembly thereof

A component installation and eccentric shaft technology, which is applied in the field of mining machinery, can solve problems such as poor load capacity, complex structure, and poor load capacity of cylindrical roller bearings, and achieve the effects of easy maintenance and inspection, high reliability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

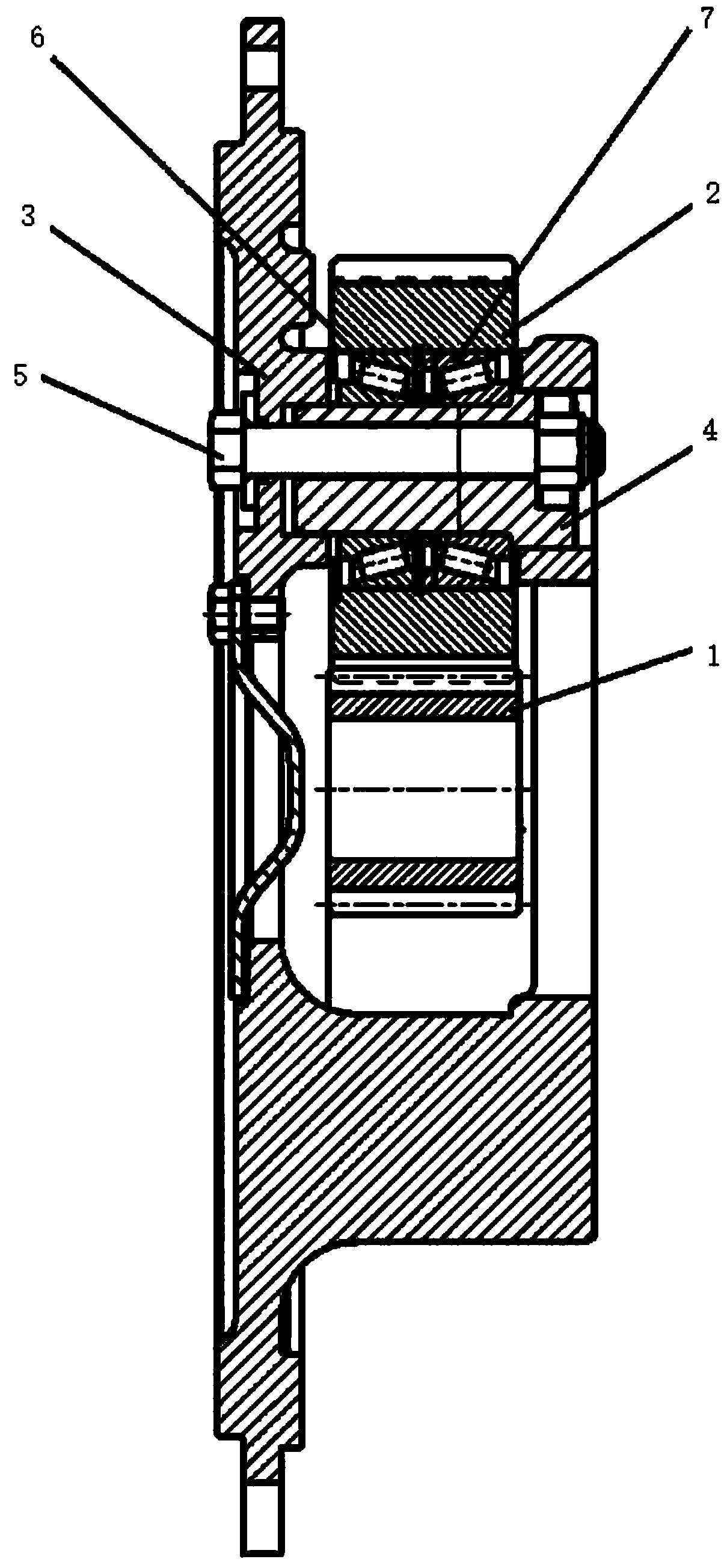

[0026] Such as figure 1 As shown, it is a schematic diagram of the overall structure of the mine wheel side reducer in the present invention.

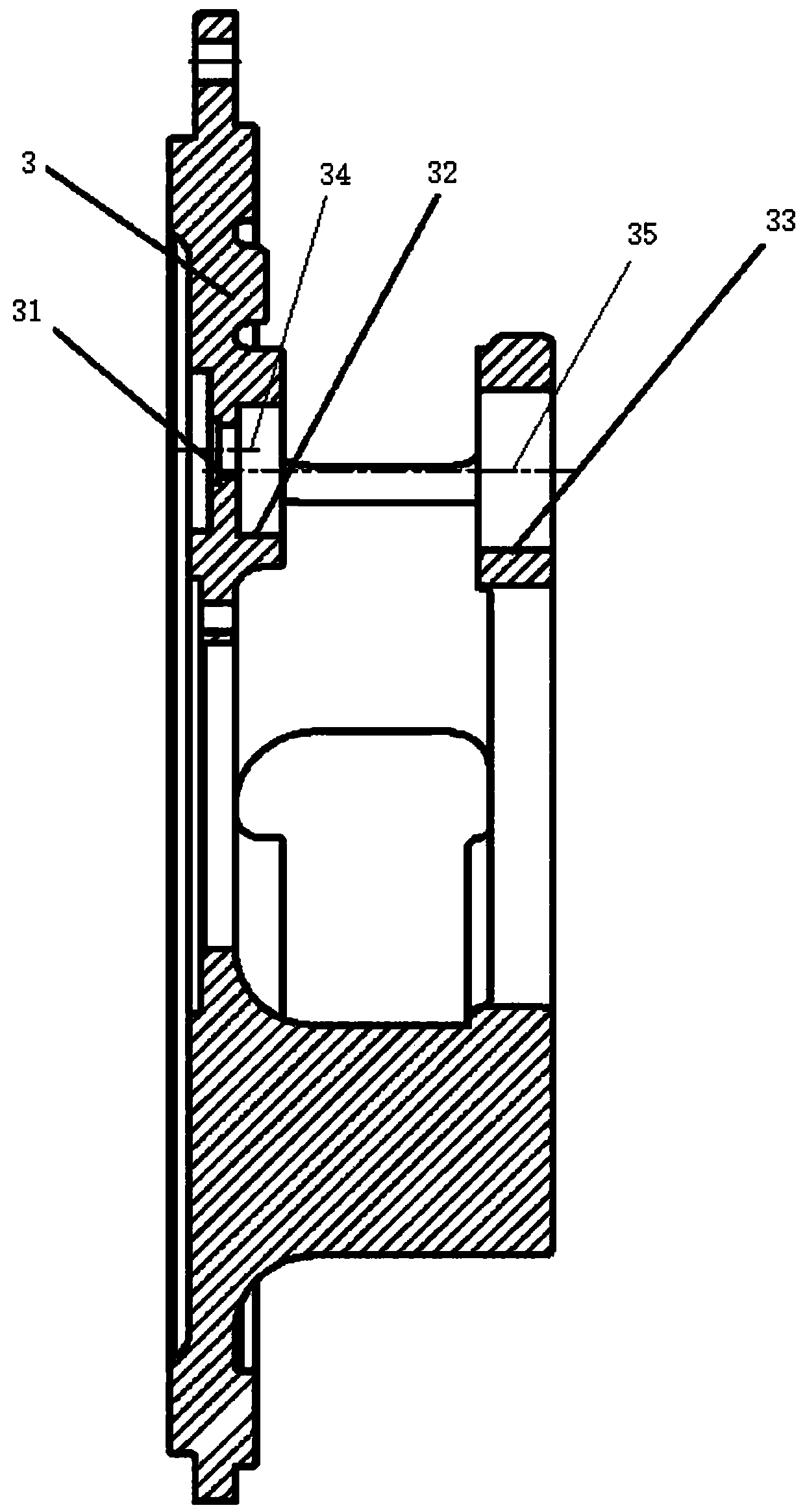

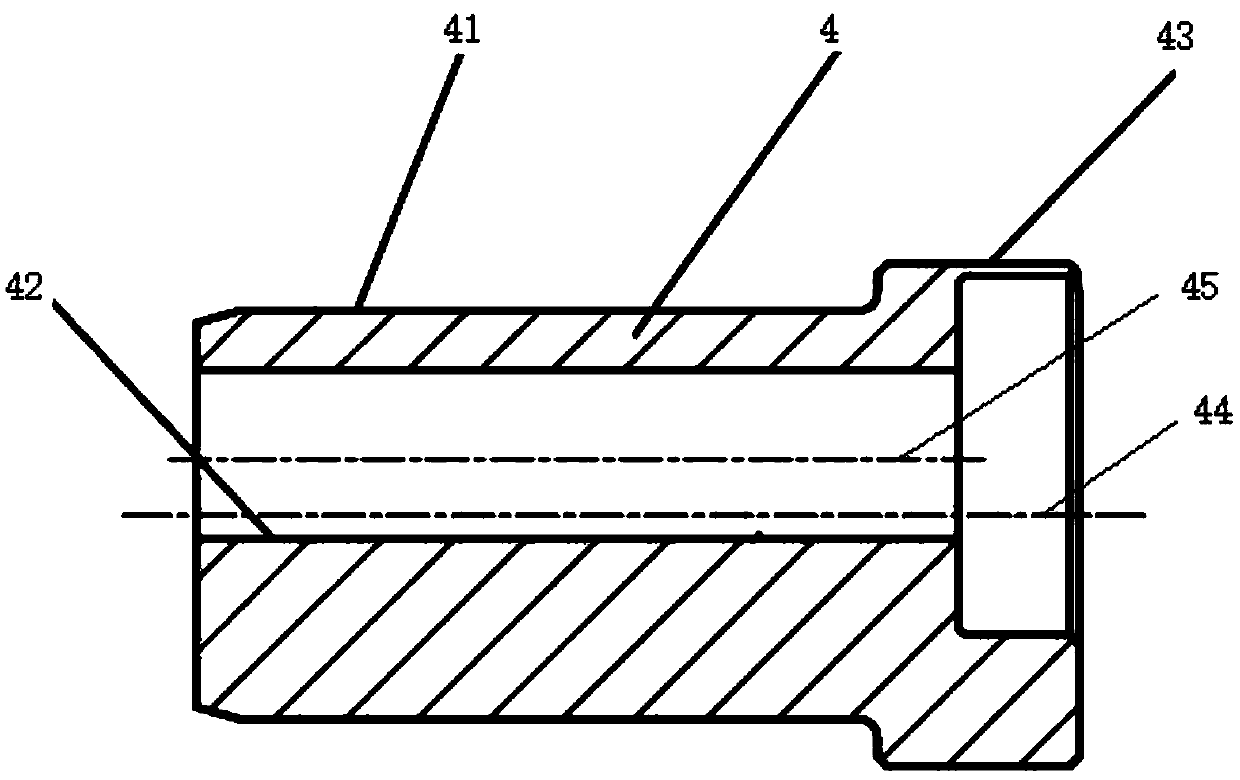

[0027] Mining wheel side reducer includes: sun gear 1, planetary gear 2, planet carrier 3, eccentric shaft 4, locking bolt 5, first tapered roller bearing 6, second tapered roller bearing 7; installation of planetary gear 2 On the first tapered roller bearing 6 and the second tapered roller bearing 7, the first tapered roller bearing 6 and the second tapered roller bearing 7 are installed on the eccentric shaft 4, and the locking bolt 5 fixes the eccentric shaft 4 on the on planet carrier 3. The eccentric shaft 4, the first tapered roller bearing 6, and the second tapered roller bearing 7 are integrally installed on the planet carrier 3, the locking bolt 5 is used to limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com