Boiler steam cleaning system

A steam and boiler technology, applied in the field of cleaning systems, can solve the problems of high manufacturing cost, high operating cost, and large floor space of boiler steam cleaners, and achieve improved steam-water separation effect, low operating cost, and small floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

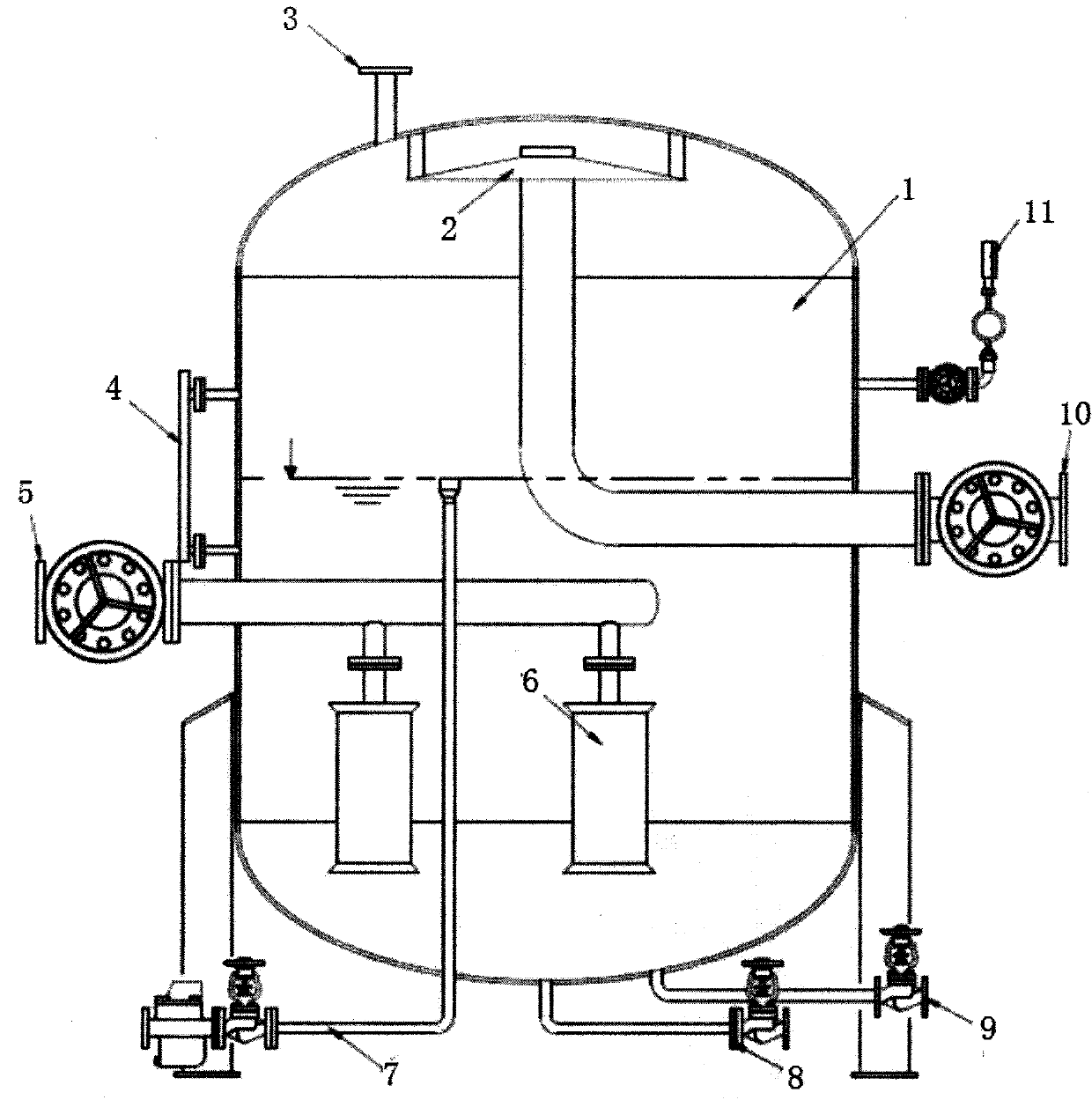

[0032] Combine below figure 1 , the present invention is further described:

[0033] like figure 1 As shown, a boiler steam cleaning system includes a vertical tank body 1, a horizontal steam inlet pipe 5 is provided through the left side wall of the tank body 1, and at least one opening is opened on the lower side of the steam inlet pipe 5 The opening of the steam inlet pipe 5 is vertically provided with at least one steam nozzle 6 opening downward, and the number of the steam nozzle 6 depends on the size of the tank body 1 .

[0034] The right side wall of the tank body 1 is provided with an "L" shaped steam outlet pipe 10, the vertical section opening of the steam outlet pipe 10 is close to the top of the tank body 1 upwards, and the opening of the vertical section is provided with centrifugal force to further separate the water droplets in the saturated steam. The conical baffle plate 2, the horizontal section opening of the steam outlet pipe 10 is located on the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com