Flexible refractive film patch with microstructure

A microstructure and film technology, applied in the field of refractive films, to achieve the effects of alleviating peripheral defocus, various design forms, and flexible shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

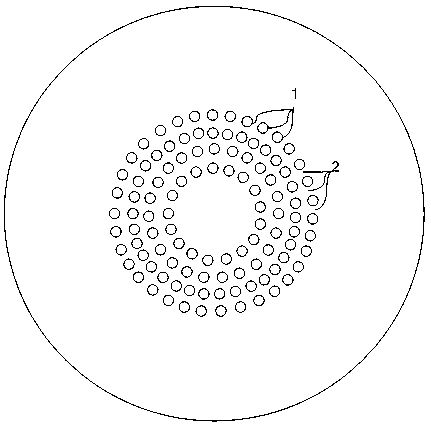

[0033] Combine now figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 The present invention is further described, as figure 1 As shown, the flexible refractive film patch with microstructure implemented by the present invention has three independent working areas, which are respectively the central optical area of zero diopter and zero prism power, and the microstructure annular zone with microlens array distribution zone, and a peripheral optic zone that has the same physical properties as the central optic zone. Wherein, the microlens array in the distribution area of the microstructure annular zone is composed of a plurality of microlens structures arranged in a certain order, and each microlens has a stable refractive power.

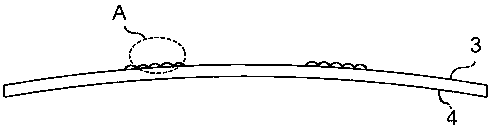

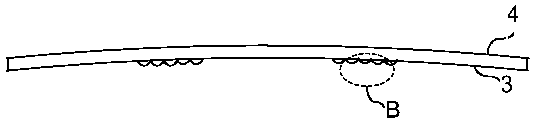

[0034] Such as figure 2 and image 3 As shown, the film patch has two sides, one side is the sticking side, and the other side is the refractive function side. The film patch also has a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com