Method and system for generating porous connected reef body based on 3D printing

A 3D printing and reef technology, applied in the field of 3D printing, can solve the problems that the model construction is difficult to meet the requirements, the adaptive structure cannot be constructed, and the satisfactory model cannot be generated, so as to achieve the advantages of internal water flow, good overall stability, The effect of facilitating the intake of bait

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

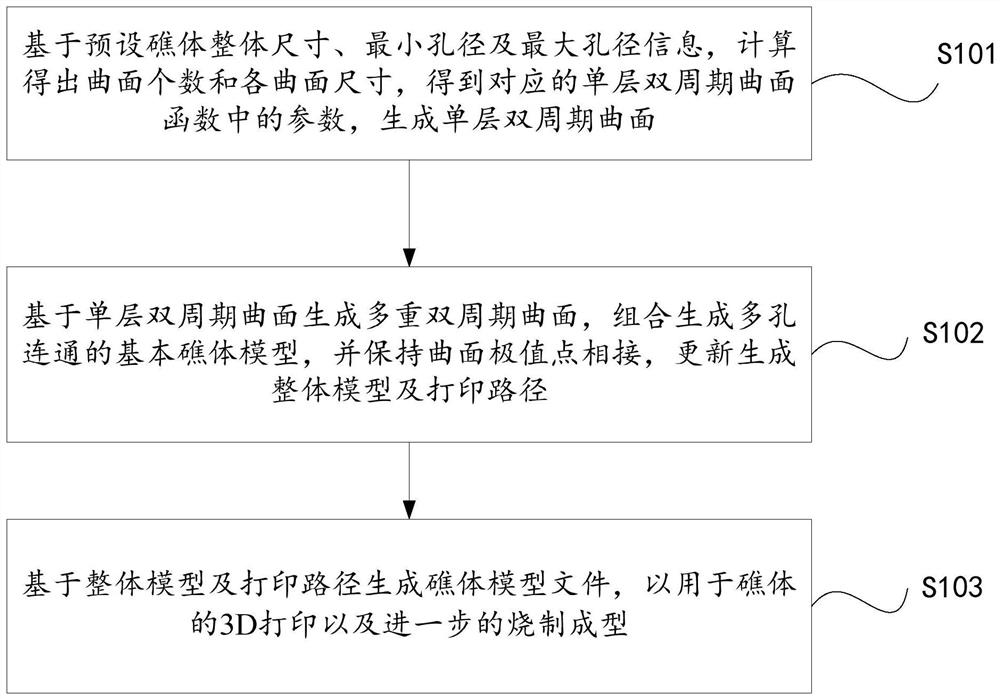

[0055] refer to figure 1 , this embodiment provides a method for generating a 3D printed porous connected reef, which specifically includes the following steps:

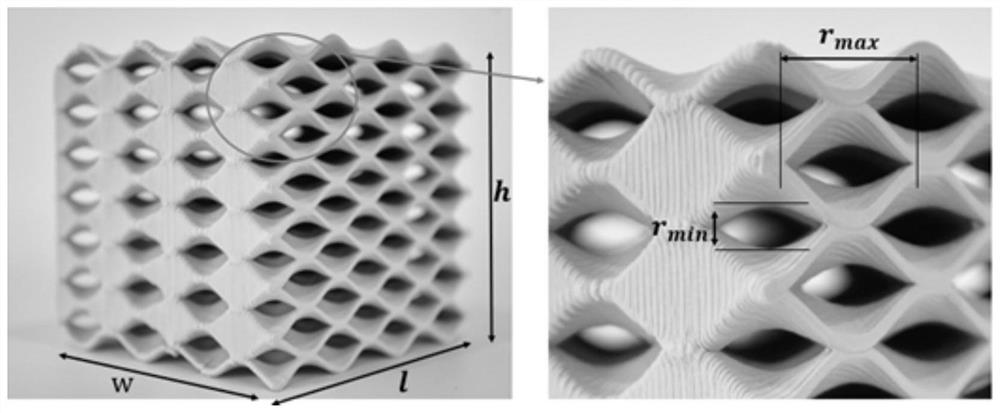

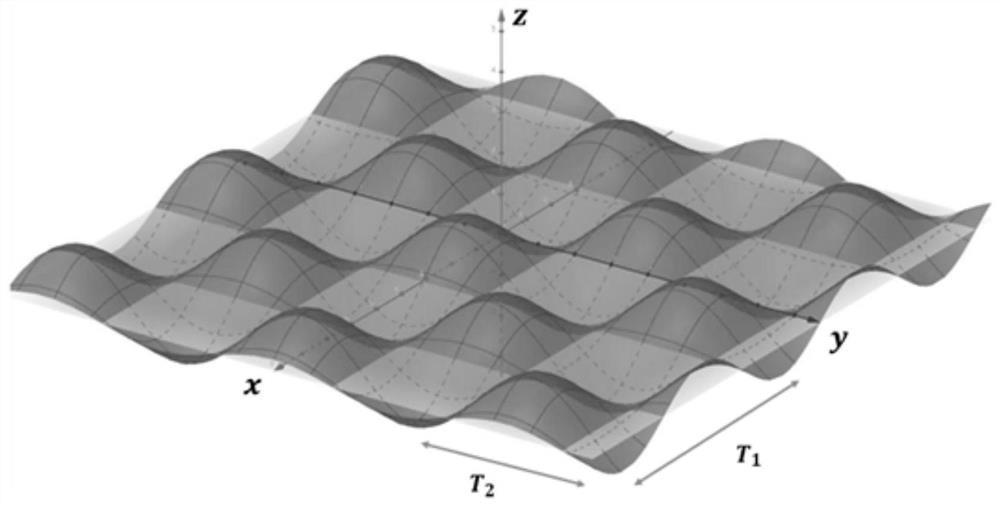

[0056] S101: Calculate the number of curved surfaces and the size of each curved surface based on the preset overall size, minimum aperture and maximum aperture information of the reef body, obtain parameters in the corresponding single-layer dual-period surface function, and generate a single-layer dual-period surface. image 3 A schematic diagram of the single-layer bi-periodic curved surface of this embodiment is given, in which x, y, and z of the coordinates correspond to the directions of the length, width, and height of the reef body, respectively. FIG. 4(a) and FIG. 4(b) respectively show a schematic diagram of the relationship between the curved surface printing path and the starting point of the adjacent printing layers in this embodiment.

[0057] The overall size of the reef and the minimum and maximum po...

Embodiment 2

[0076] This embodiment provides a 3D printed porous connected reef generation system, which specifically includes the following modules:

[0077] The single-layer dual-period surface generation module is used to calculate the number of surfaces and the size of each surface based on the preset reef overall size, minimum aperture and maximum aperture information, and obtain the corresponding parameters in the single-layer dual-period surface function, Generate a single-layer biperiodic surface;

[0078] The overall model and printing path generation module is used to generate multiple bi-periodic surfaces based on single-layer bi-periodic surfaces, combine to generate a basic reef model with porous connectivity, and keep the surface extreme points connected, and update the overall model and printing path;

[0079] The reef model file generation module is used to generate the reef model file based on the overall model and the printing path, for 3D printing and further firing of t...

Embodiment 3

[0082] This embodiment provides a computer-readable storage medium on which a computer program is stored, and when the program is executed by a processor, implements the steps in the above-mentioned method for generating a 3D printed porous connected reef.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com