Fixing method of induction coil

A technology of induction coil and fixing method, applied in the direction of coil, coil manufacturing, electrical components, etc., can solve the problems of inaccurate induction, short service life, parameter change, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

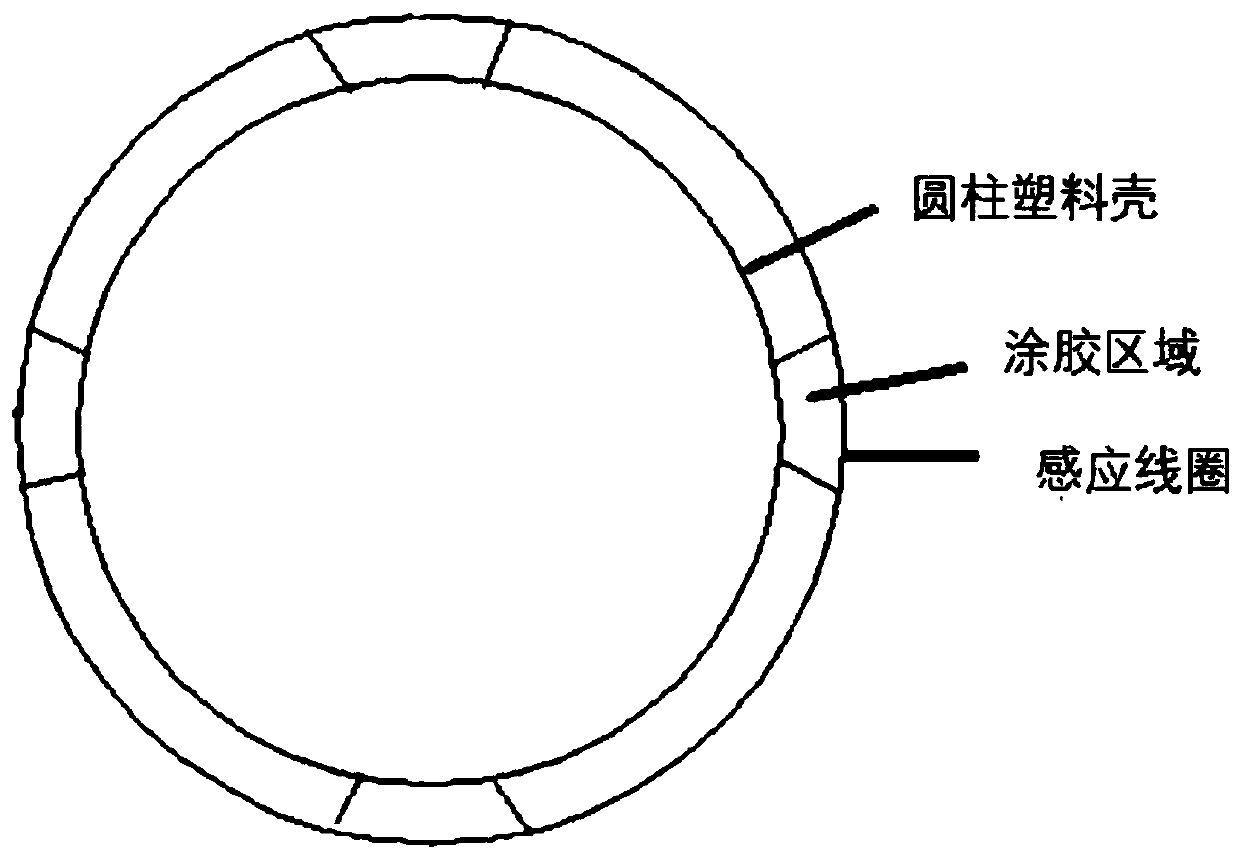

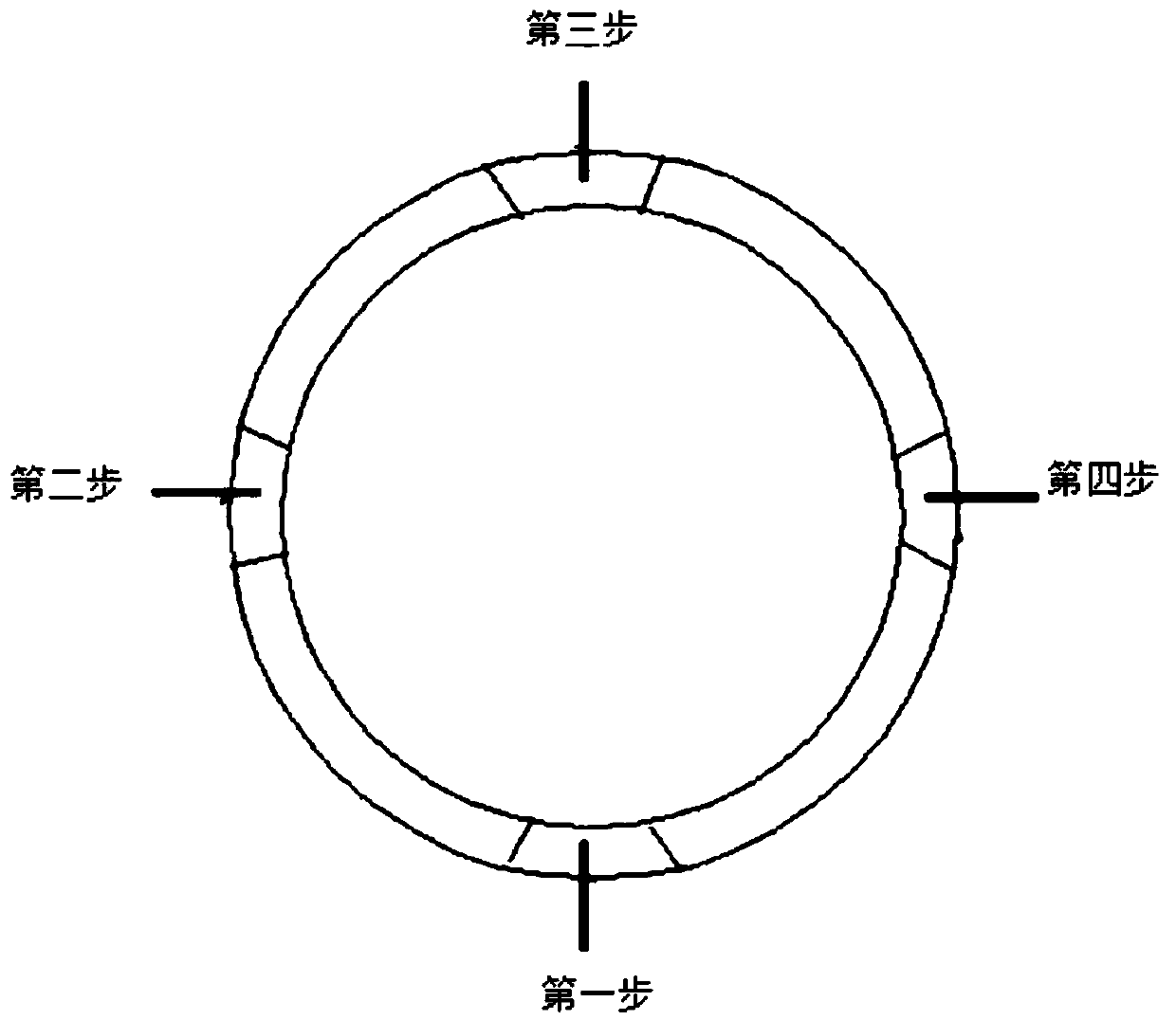

[0008] figure 1 It is a schematic diagram of the structure of the present invention. After winding the induction coil with a multi-strand wire on the plastic shell with a through hole in the middle of the cylinder, place it horizontally and use a multimeter to measure and record its various parameters, which are inductance, D, parasitic capacitance, and Q value respectively. , AC resistance and DC resistance. The induction coil is fixed by using a modified acrylate adhesive with fast curing speed and high bonding strength, which is suitable for bonding various industrial materials. Because if the glue is applied to the induction coil, although the relative position between the wires in the coil can be kept unchanged, and its parameters are stable, this will reduce the horizontal and vertical line spacing of the induction coil too much. As a result, the Q value decreases, the inductance and AC resistance increase, and the ideal state after the induction coil is fixed is that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com