Two-color temperature flexible filament and packaging method thereof

A dual-color temperature and filament technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of complex production process, cumbersome process, unsightly and other problems, and achieve the effect of simple production process, simplified production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

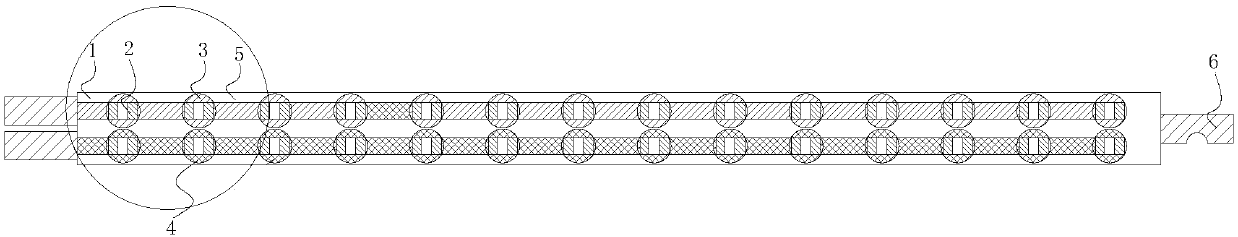

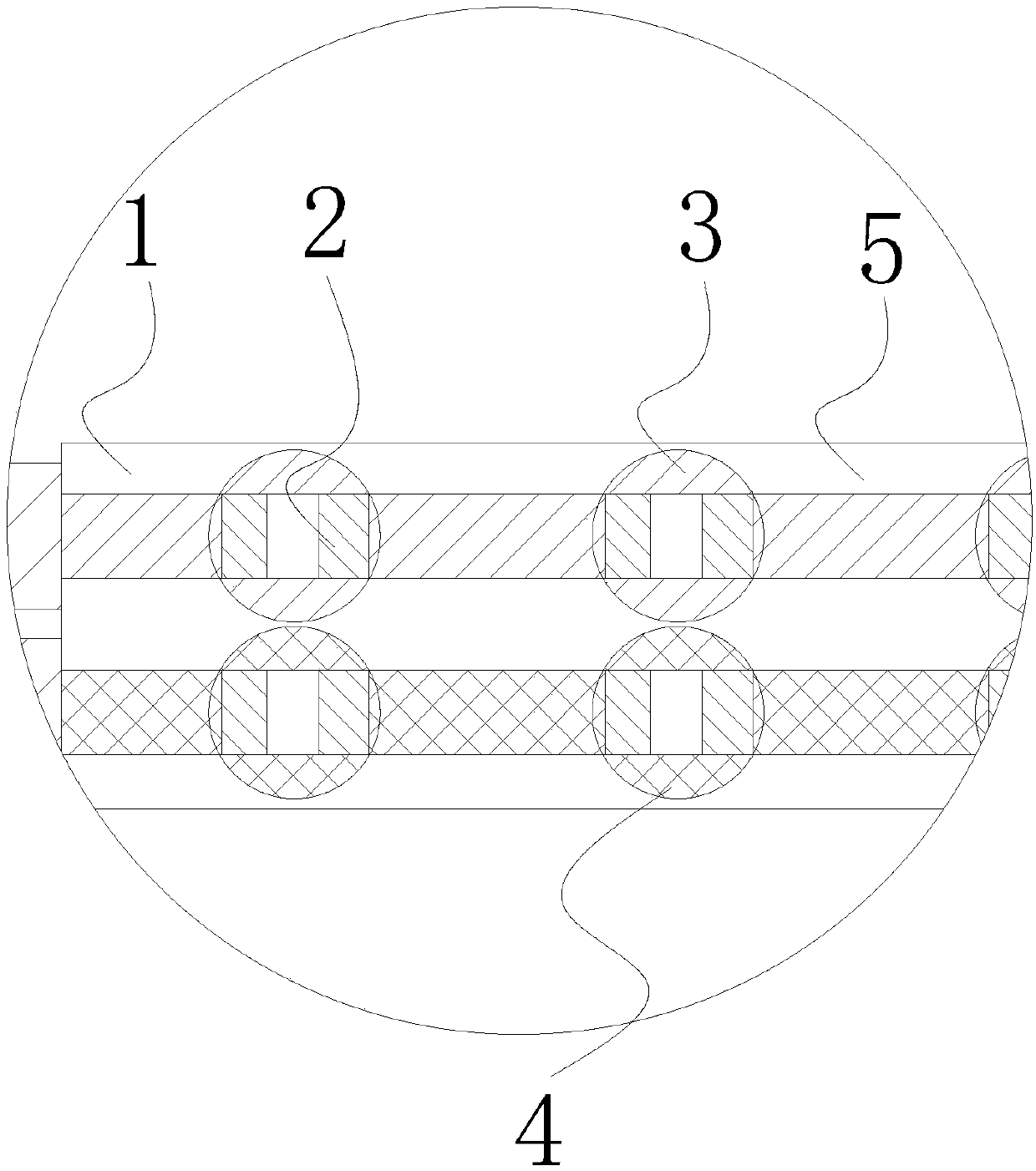

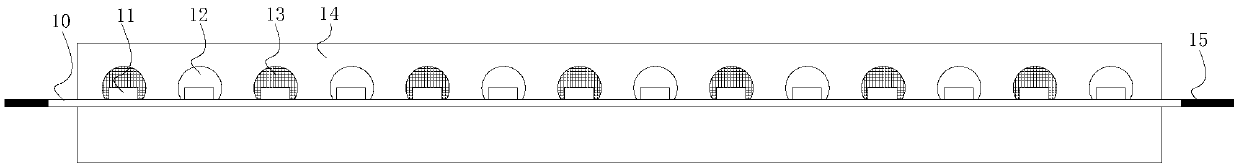

[0035] See attached Figure 1-2 , a flexible filament with dual color temperature according to the present invention, including a flexible substrate 1; two circuits arranged in parallel on the flexible substrate 1 (not shown in the figure); Flip-chip LED chips 2, the above two groups of flip-chip LED chips 2 are respectively connected to two circuits; low color temperature silica gel phosphor mixture 3, coated on the front and back of any set of flip-chip LED chips 2; high color temperature silica gel phosphor powder The mixture 4 is coated on the front and back of another group of flip-chip LED chips 2, and the method of coating with equipment is uniformly coated on the flip-chip LED chips 2 according to different color temperatures.

[0036] As a further preferred embodiment, the flexible filament with two color temperatures is coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com