Electrical hidden wiring layout structure based on dispenser equipment

A layout structure and hidden technology, applied in the direction of electrical components, etc., can solve the problems of occupying equipment space, dust is not easy to clean, and is not beautiful, so as to achieve the effect of reducing the effective width space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

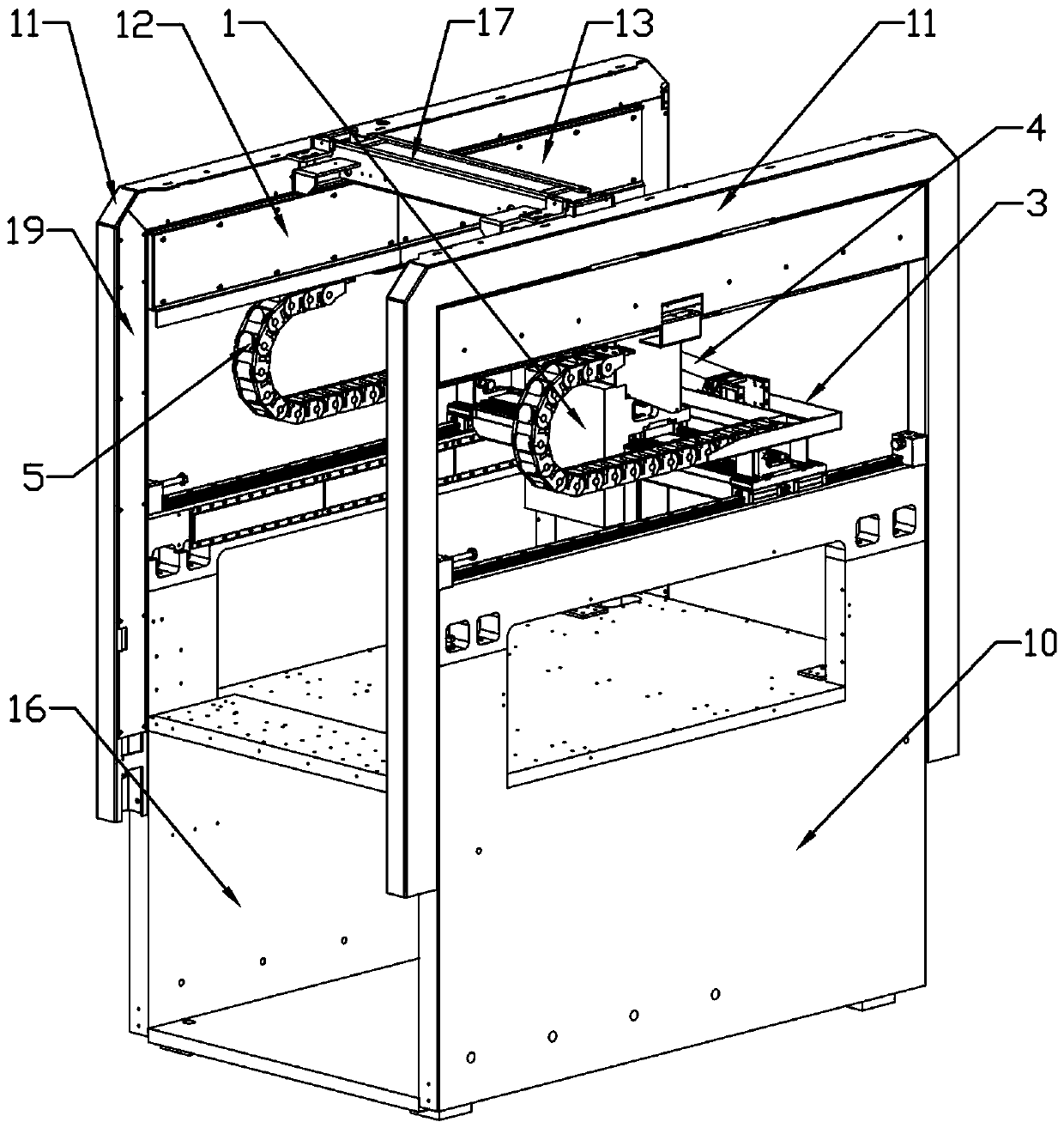

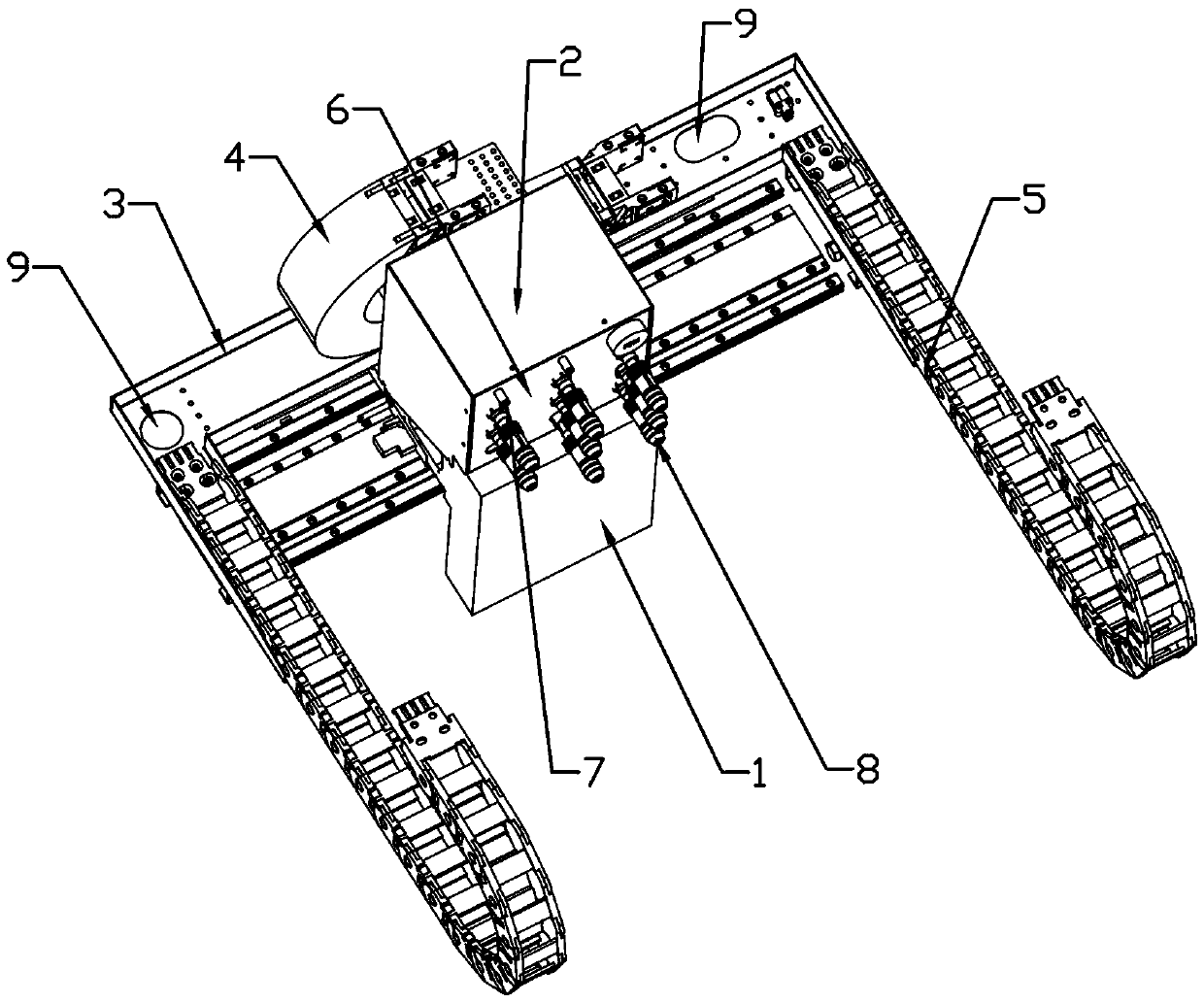

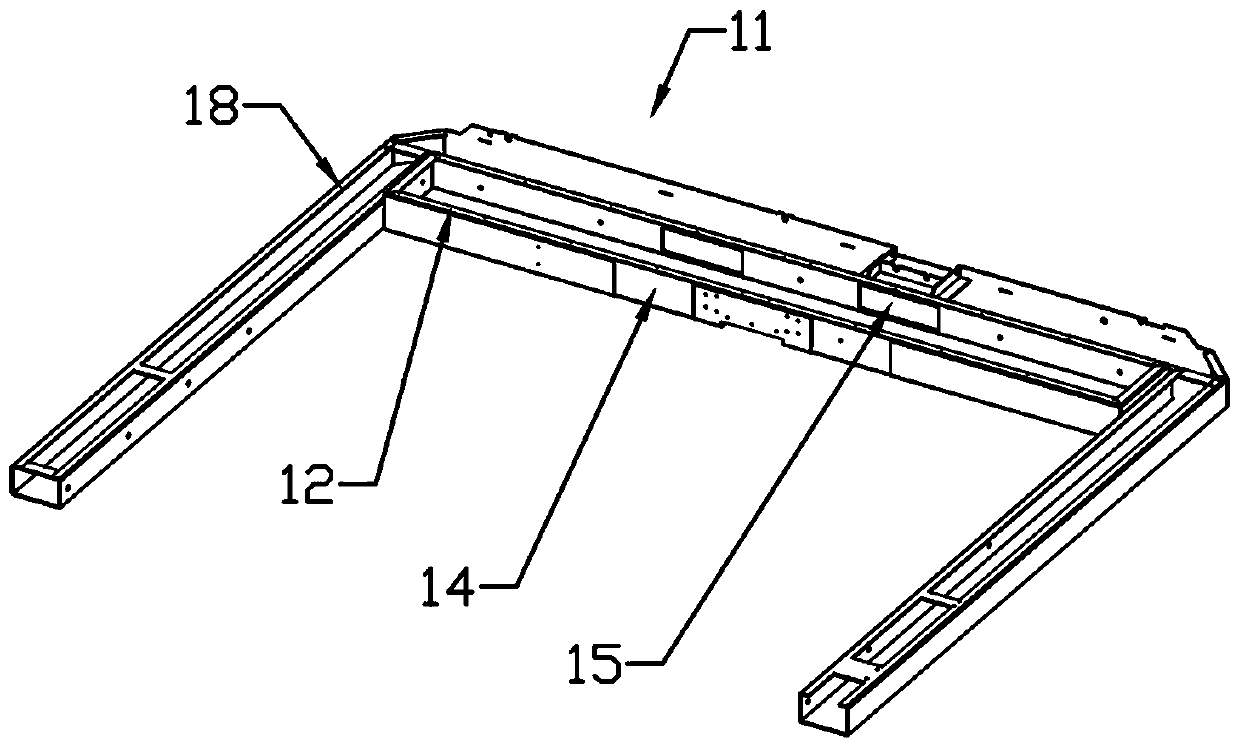

[0020] Such as Figure 1 to Figure 3 As shown, the specific embodiment of the present invention is: the present invention includes a working unit 1, a junction box 2, an installation beam 3 arranged in the X axial direction, an X-axis drag chain 4 arranged at the rear of the junction box 2, a set Two sets of Y-axis drag chains 5 on the left and right sides of the installation beam 3, the junction box 2 is provided with a junction box panel 6, and the junction box panel 6 is provided with a number of air pipe joints 7 and a number of wires. Cable joint 8, the air pipe line and cable of the working unit 1 are matched with the air pipe joint 7 and the cable joint 8 respectively, and the line entry end of the X-axis drag chain 4 is connected with the junction box 2 connected, the outlet end of the X-axis towline 4 and the inlet end of the Y-axis towline 5 are connected to the installation beam 3, and the two ends of the installation beam 3 are provided with the first up and down p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com