Tank

A fuel tank and steering plate technology, applied in the direction of fuel supply tank devices, mechanical equipment, etc., can solve problems such as overheating and pollution, achieve full degassing, reduce the volume of the fuel tank, and improve the effect of degassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

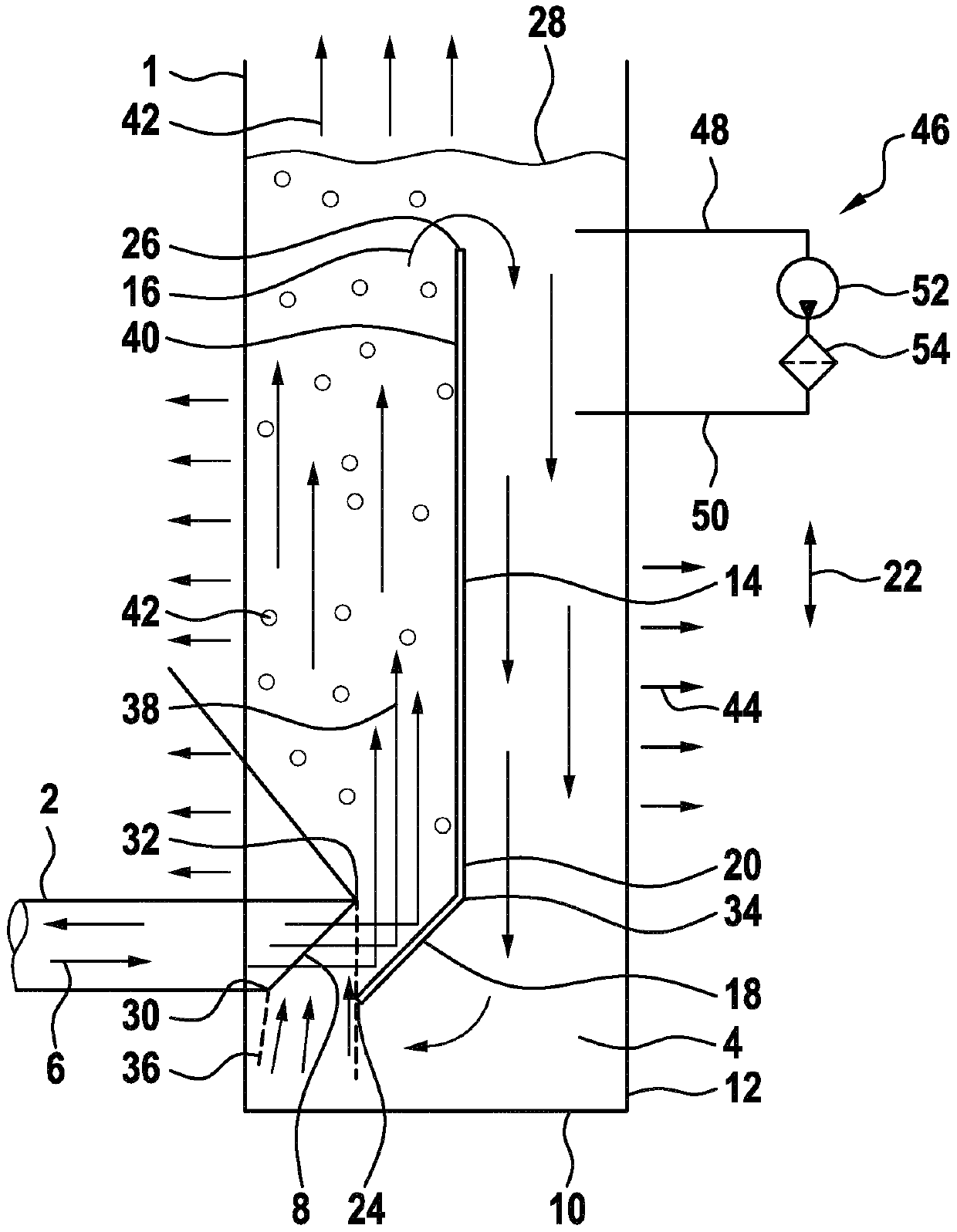

[0028] According to this figure, the tank 1 has a connecting line 2 . Oil can be fed into or removed from the interior 4 of the oil tank via the connecting line. Here, in particular, periodically alternating flow directions 6 are provided in the connecting line 2 . The connecting line 2 has a nozzle opening 8 which extends approximately obliquely with respect to the vertical. The nozzle opening 8 faces here in the direction of the bottom side 10 and the side wall 12 of the tank 1 . A deflection plate 14 is arranged in the tank 1 at a distance from the nozzle opening 8 . The oil flowing into the oil tank via the connection line 2 can be deflected upwards by means of the deflector plate, which overall leads to a circulating flow 16 of oil around the deflector plate 14 .

[0029] The deflection plate 14 has a deflection section 18 and a guide section 20 . The sections 18 , 20 are arranged in an angled manner relative to each other. In particular, the deflection section 18 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com