A system and implementation method for orderly harvesting of leafy vegetables on the same machine

A technology of binding strips and leafy vegetables, which is applied in the field of agricultural equipment, can solve the problems of loose loading, small conveying capacity, difficulties in collection, transportation and processing, etc., and achieve the effect of fast bundling, avoiding damage, simple and reliable structure and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

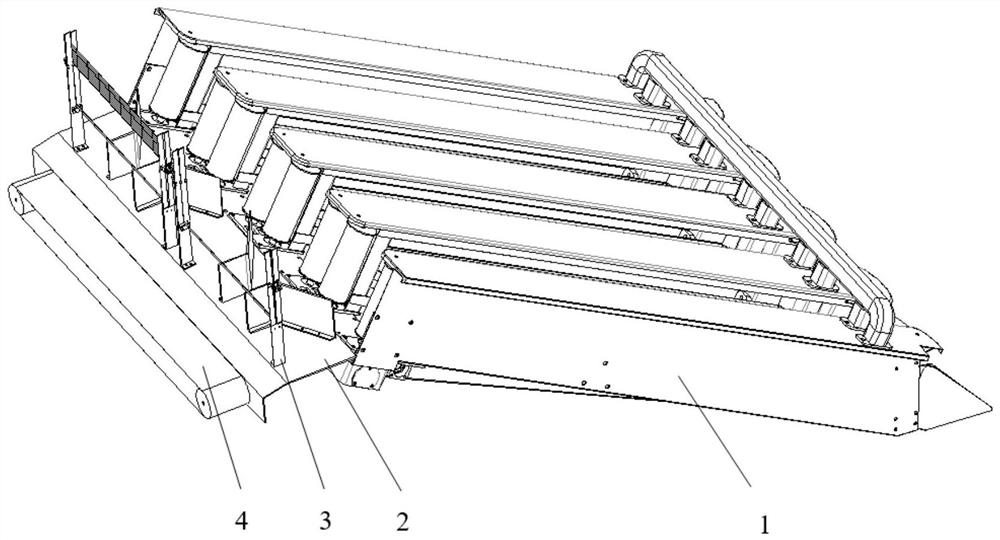

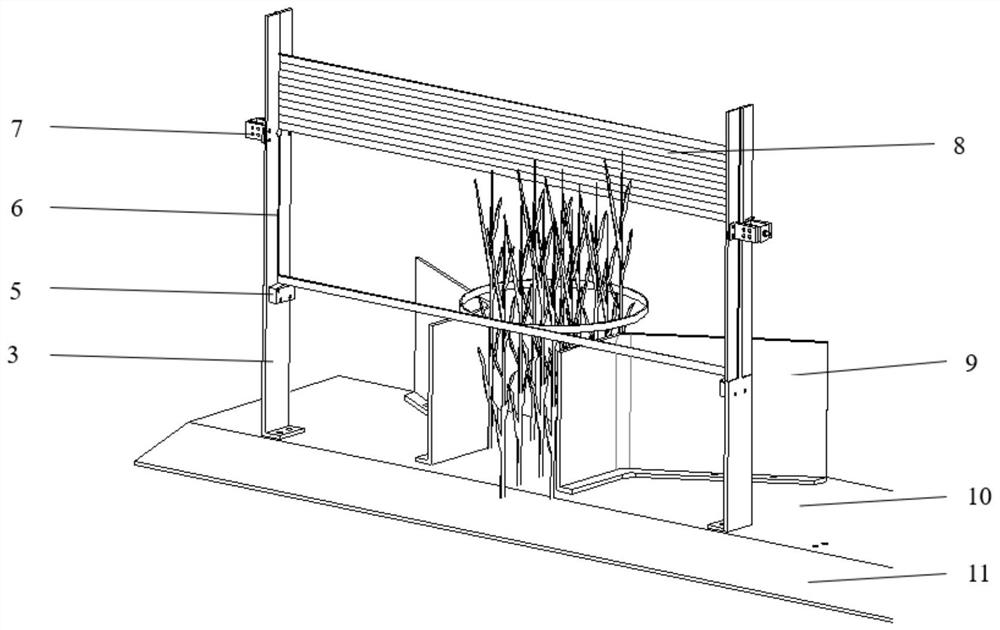

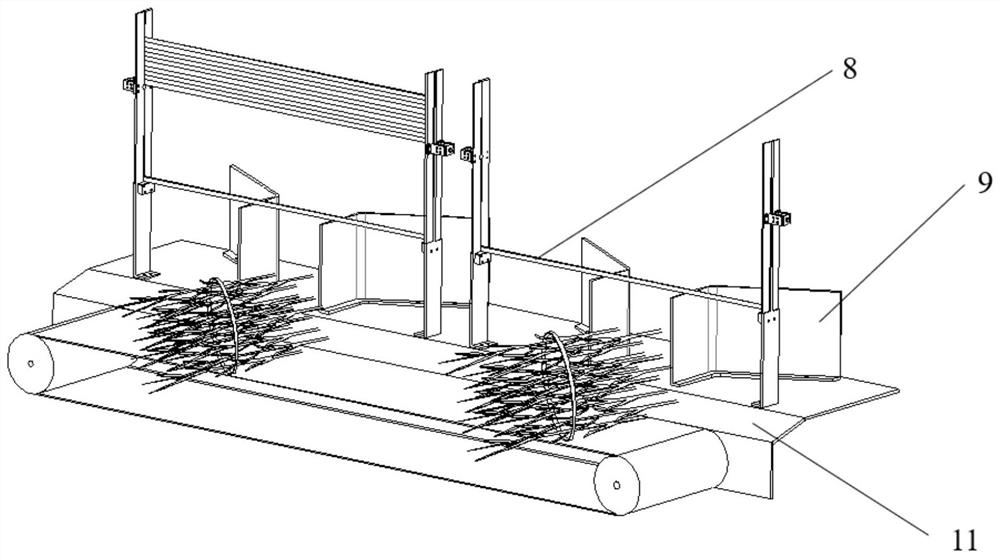

[0025] refer to figure 1 , after the orderly leafy vegetable harvester completes the leafy vegetable cutting, the leafy vegetables are held by the branch clamping and orderly conveying system 1 and divided into N rows for orderly upward transport, and the same machine binding and bundling system for orderly harvesting of leafy vegetables is installed At the exit of the sequential conveying system 1 held by the branch, such as figure 1 As shown, the same-machine binding system for orderly harvesting leaf vegetables is composed of a bottom plate 2, n binding mechanisms, and a horizontal conveying mechanism 4. figure 1 The number n of the bundling mechanisms in the middle tie is 2. n strip binding mechanisms are installed on the bottom plate 2 along the same vertical plane in the horizontal direction, each bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com