Automatic making device for egg tarts

A production device and egg tart technology, which is applied in the cleaning device of the baking cavity, dough sheeting machine/rolling machine/rolling pin, baking, etc., can solve the problem of low automation, no taste, and no egg tart production Process and other issues, to achieve good crisping effect, crisp taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

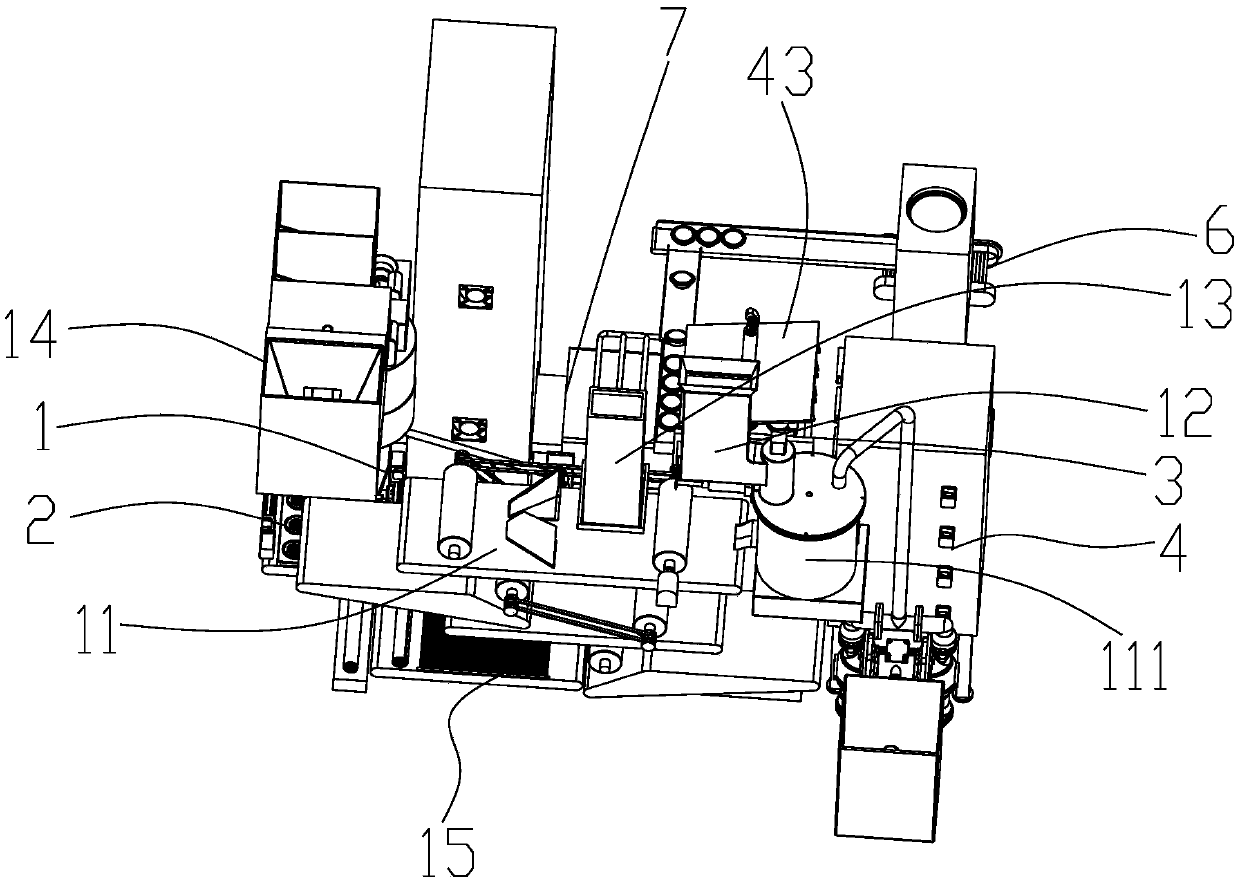

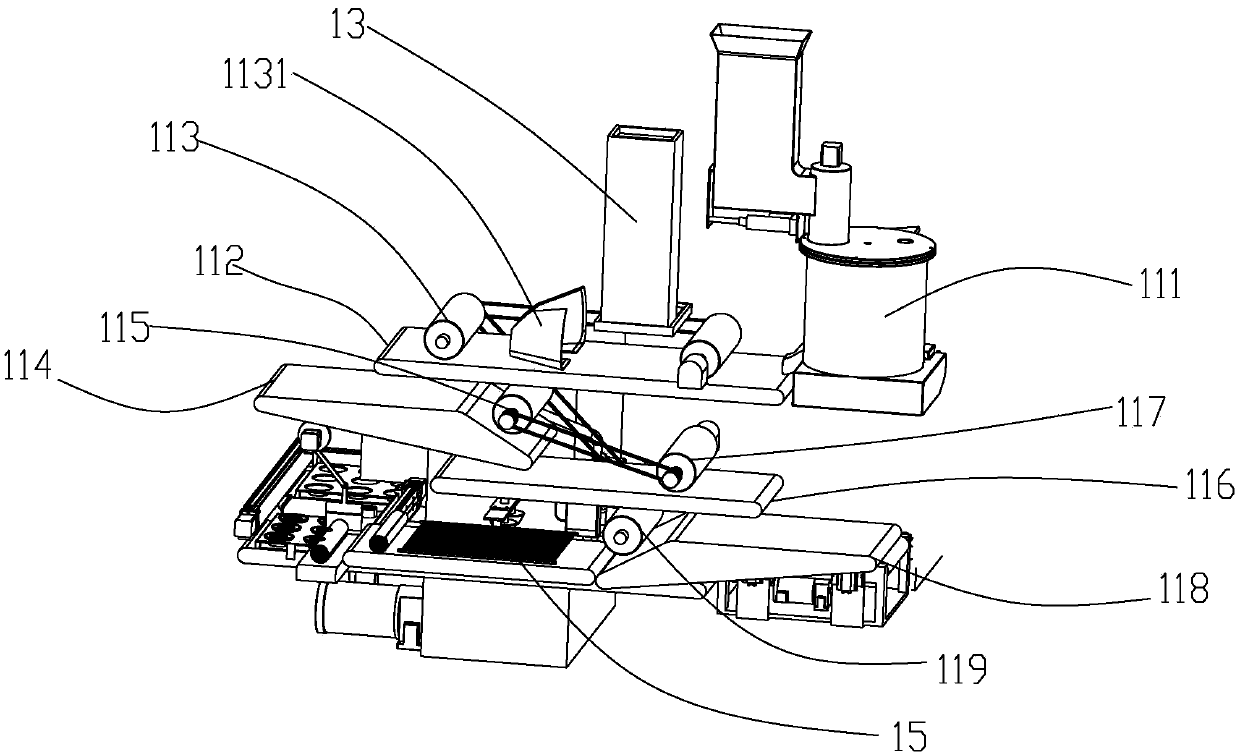

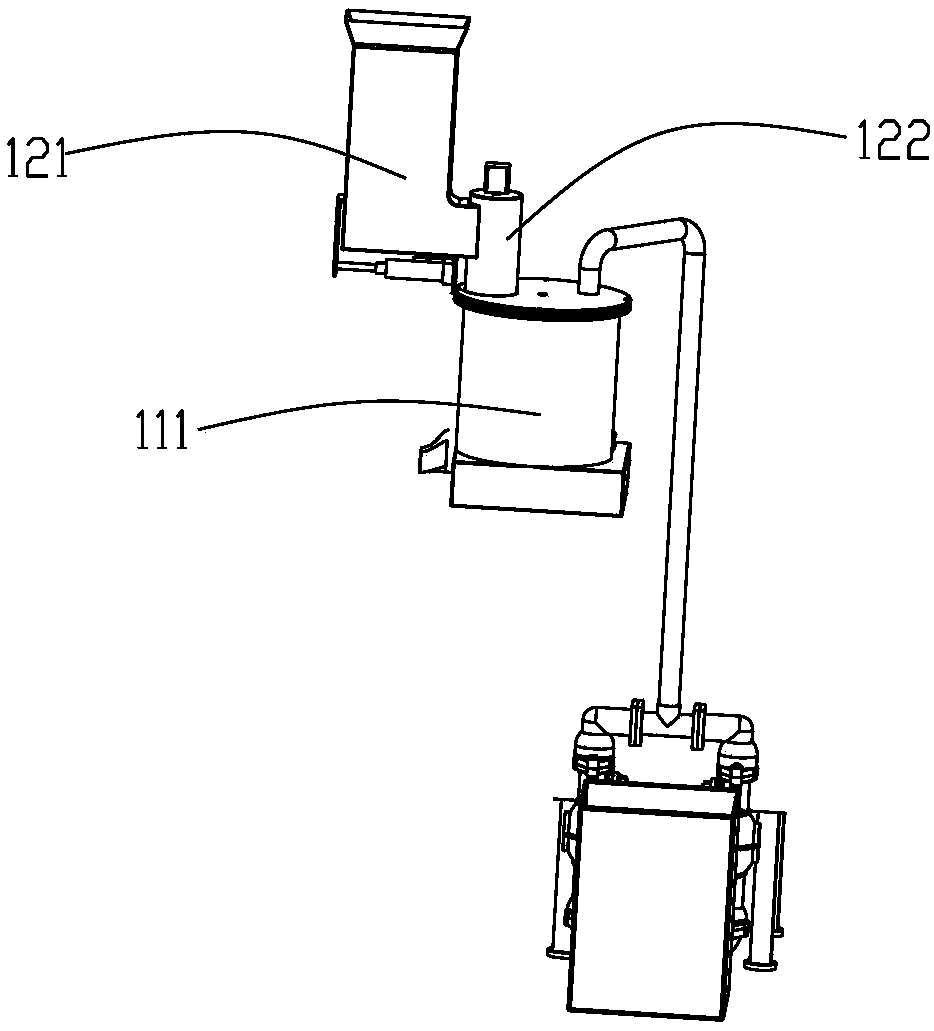

[0076] The present invention as figure 1 As shown, it includes a batching production device 1, a baking tray conveying device 2, a transfer platform 3, an oven 4, a discharging device 5, an egg tart transportation device 6 and a baking tray recycling device 7 arranged on the frame; Device 1 comprises puff pastry production device 11 and egg tart liquid production device 14, and the puff pastry made by described puff pastry production device 11 drops on the baking pan conveyed via baking pan delivery device 2, and described egg tart liquid production device 14 passes through Adding pipe 143 adds egg tart liquid to the meringue placed on the baking tray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com