Method for achieving water-passing oil-blocking type oil-water separation by using super-double-hydrophobic or double-hydrophobic net membrane

A technology for oil-water separation and dredging membrane, which is applied in separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of difficult preparation, difficulty in realizing oil-water separation through oil-blocking and water-passing, and blocking mesh holes by filtration. Achieve the effect of low cost and energy consumption, greatly reduced overcoming efficiency and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

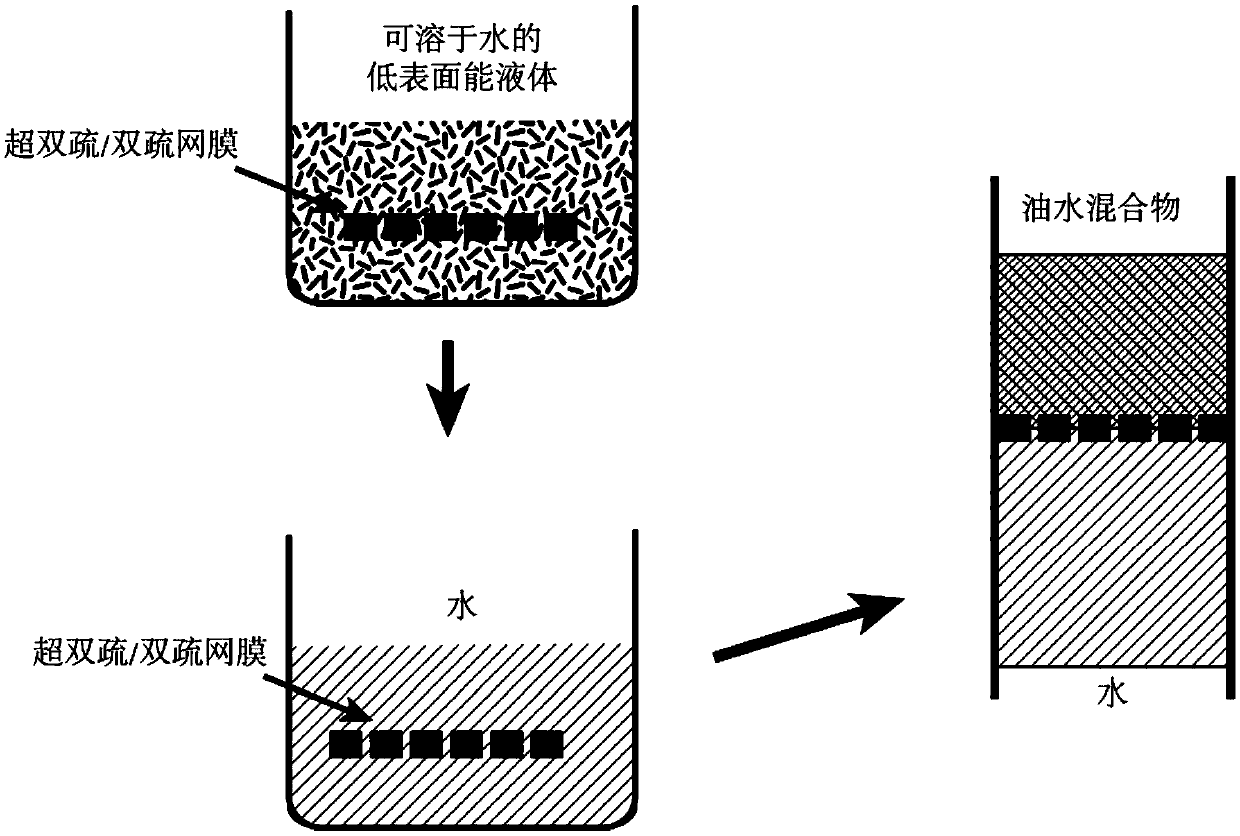

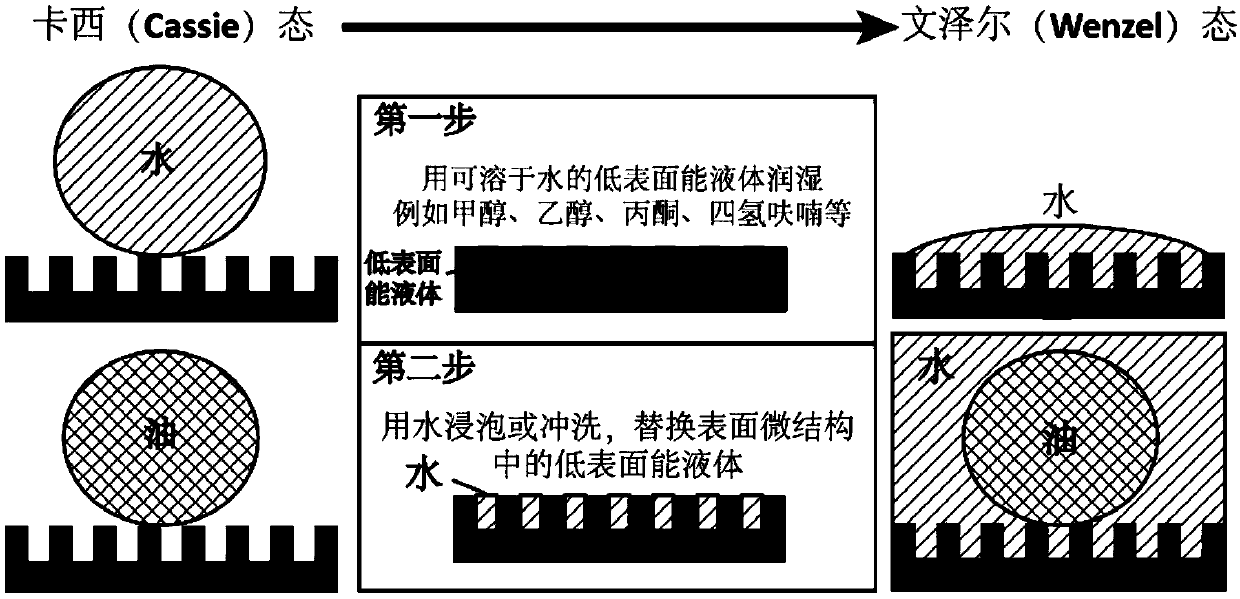

[0021] Specific implementation mode 1: The specific process of the method for realizing oil-blocking and water-flowing oil-water separation using super-amphiphobic or amphiphobic omentum in this embodiment is as follows:

[0022] Step 1: making a water-soluble liquid with low surface energy wet a part or the whole of the superamphiphobic or amphiphobic omentum by means of spraying or soaking;

[0023] Super-amphiphobic means that the contact angles of oil and water with solid surfaces are greater than 155 degrees;

[0024] Amphiphobic means that the contact angles of oil and water with solid surfaces are both greater than 90 degrees and less than or equal to 155 degrees;

[0025] The specific amount of low surface energy is actually related to the oleophobicity of the super-amphiphobic or amphobic surface, which is low enough to wet the super-amphiphobic or amphobic surface. For example, it is generally used that the surface energy at room temperature is less than 0.03N / m as ...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment differs from Embodiment 1 in that the water-soluble liquid with low surface energy in step 1 is ethanol, methanol, acetone, tetrahydrofuran, or an aqueous solution containing a surfactant.

[0031] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in the step 1, the super-amphiphobic omentum behaves as super-hydrophobic and super-oleophobic in the air, so that neither oil nor water can pass through the network. membrane.

[0033] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com