Mechanical gripper with adjustable width

A manipulator gripper and adjustable technology, applied in the field of manipulator grippers, can solve the problems of processing stagnation, low processing efficiency, and high error rate of pneumatic grippers, and achieve the effects of reducing loss, improving safety, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

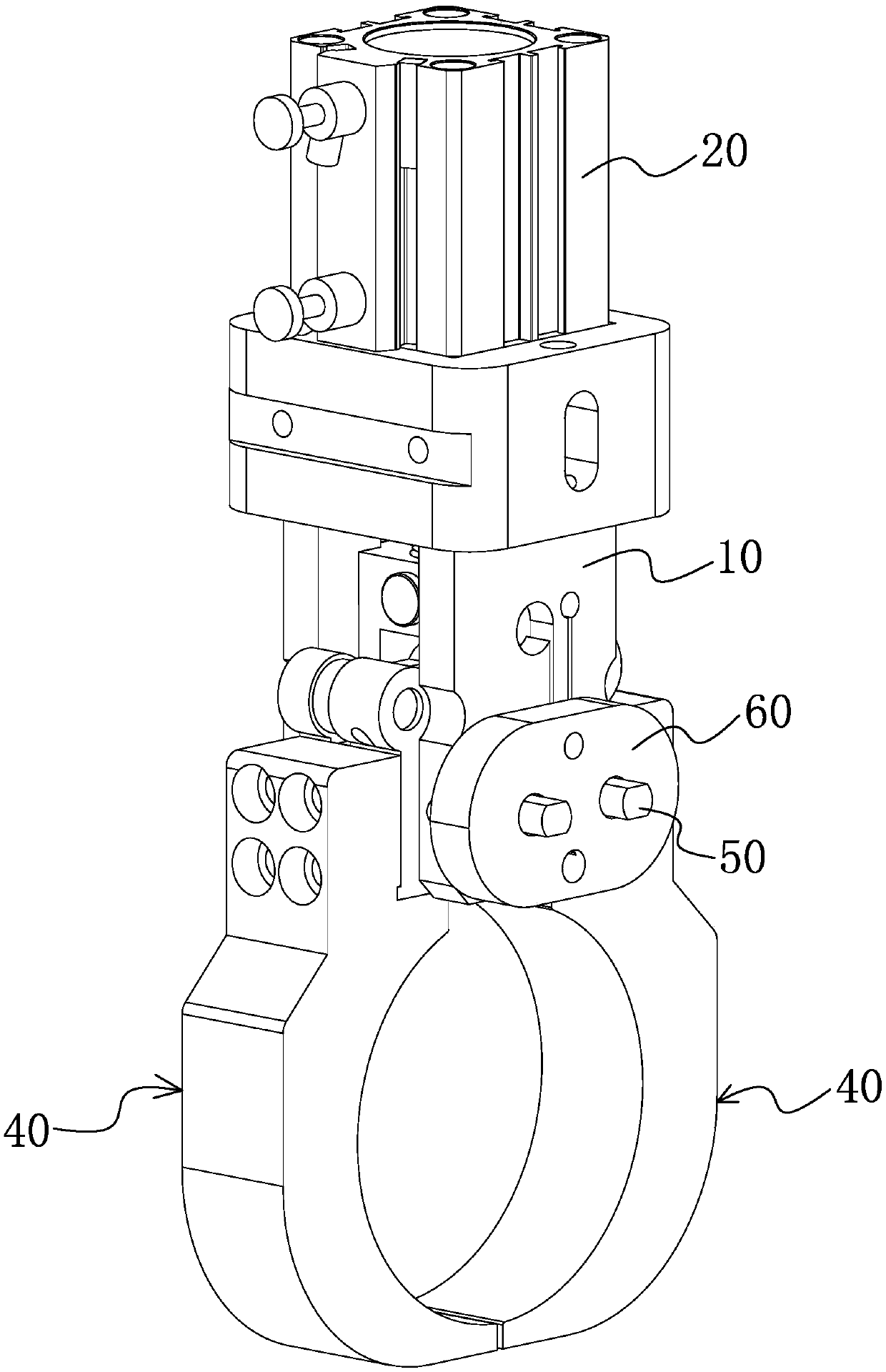

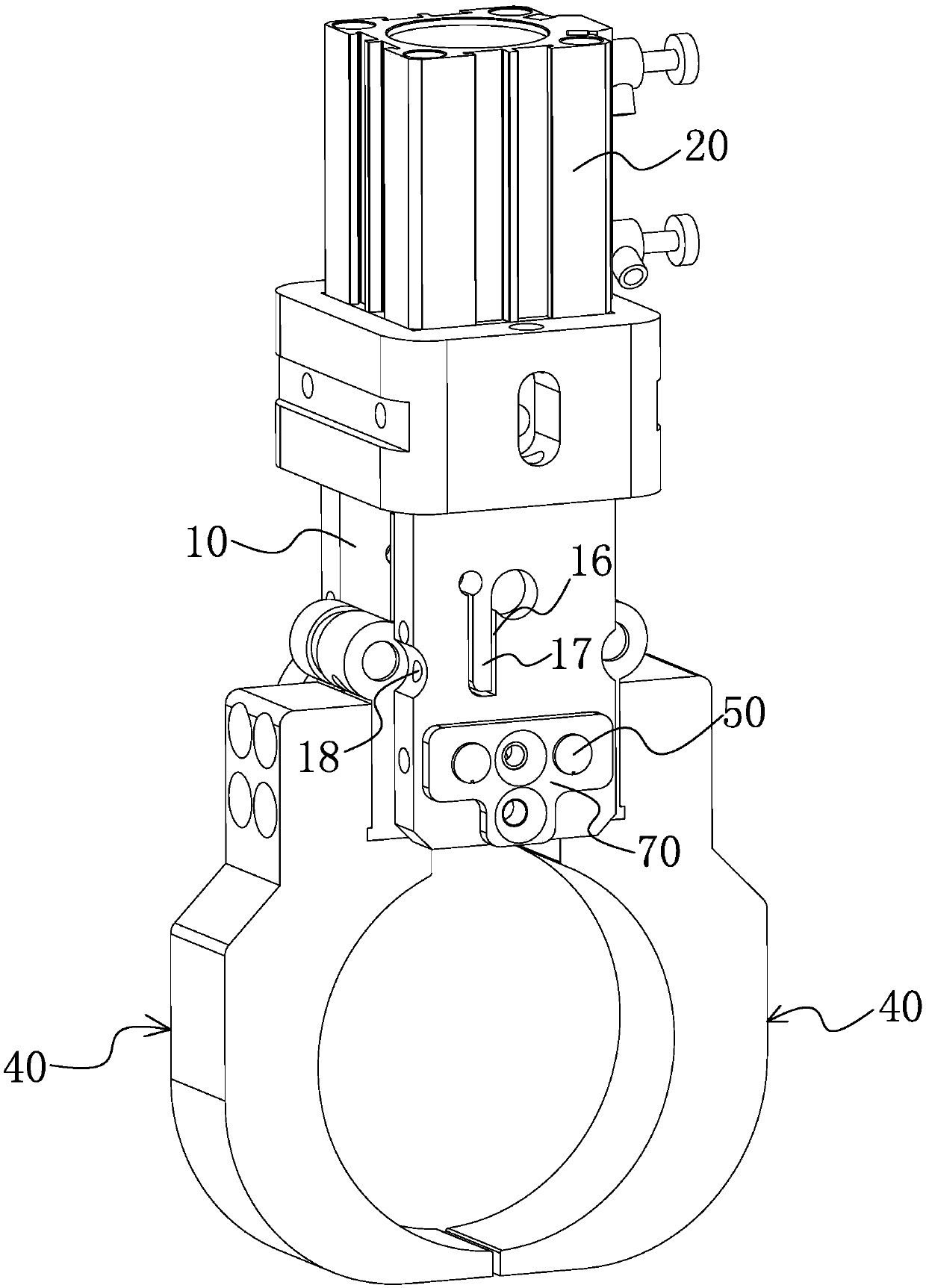

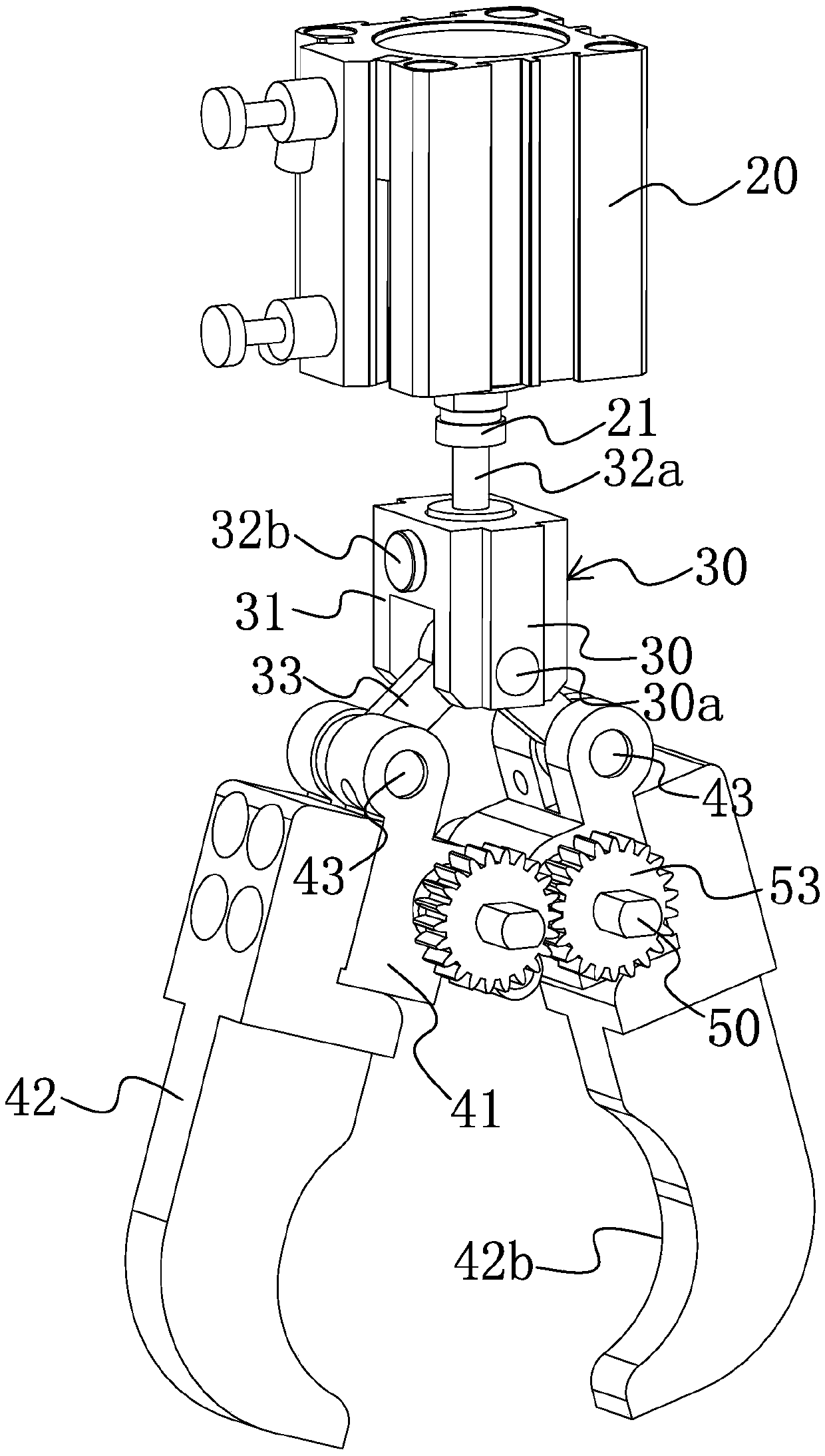

[0042] Such as Figure 1-Figure 4 As shown, a width-adjustable mechanical gripper device of the present invention includes a mounting base 10 , a driving member, a transmission member 30 , a gripper 40 and an eccentric shaft 50 .

[0043] The mounting base 10 is an inner hollow structure, and its bottom is provided with an assembly groove 11 that runs through the mounting base 10 transversely, and the driving member is fixedly connected with the top of the mounting base 10. Preferably, the driving member is a driving cylinder 20, and a piston rod 21 of the driving cylinder 20 Extending into the mounting base 10, the transmission part 30 is set in the mounting base 10 and connected with the driving part, there are two gripp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com