Preparing method of 3D printing intelligent deforming material

A deformation material and 3D printing technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of destroying polymer compound groups, loss of deformation performance, high printing temperature, etc., to simplify processing steps, promote deformation, The effect of lowering the printing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

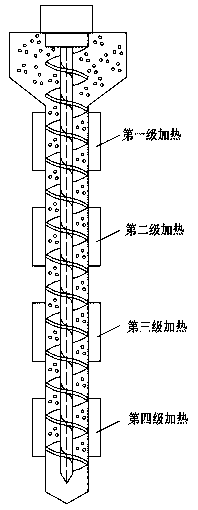

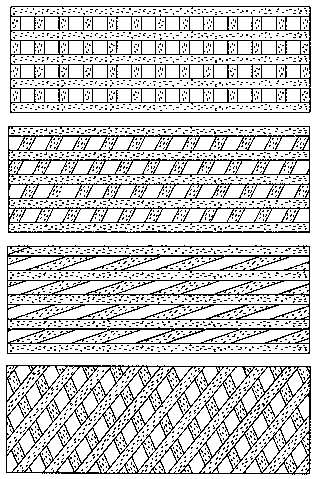

[0027] see figure 1 , 2 , as shown in 3:

[0028] The first step, the preparation of polymer filament:

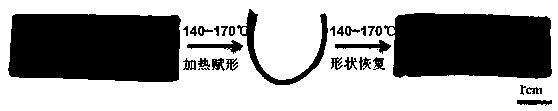

[0029] Take 95% of polyether ether ketone powder and 5% of carbon fiber according to the mass percentage, and stir and mix for 8-10 minutes. After mixing evenly, put the mixture into the heating extrusion device for heating and melting. The heating extrusion device includes four stages of heating in sequence. The first-stage heating temperature is 120°C-140°C, the second-stage heating temperature is 180°C-200°C, the third-stage heating temperature is 240°C-260°C, and the fourth-stage heating temperature is 320°C-360°C. The mixture is heated to a semi-molten state. Through screw extrusion, the screw speed is 110rpm~140rpm, the diameter of the extrusion head is 1mm~3mm, after heating, it is extruded into the cooling water tank at 25℃~40℃ by the heating extrusion device for cooling, and made into silk Materials, as consumables for 3D printing;

[0030] The second step, 3D ...

Embodiment 2

[0034] see figure 1 , 4 , as shown in 5:

[0035] The first step, the preparation of polymer filament:

[0036]Take 80% of polyetheretherketone powder and 20% of carbon fiber according to the mass percentage, and stir and mix for 8-10 minutes. After mixing evenly, put the mixture into the heating extrusion device for heating and melting. The first-stage heating temperature is 120°C-140°C, the second-stage heating temperature is 180°C-200°C, the third-stage heating temperature is 240°C-260°C, and the fourth-stage heating temperature is 320°C-360°C. The mixture is heated to a semi-molten state. Through screw extrusion, the screw speed is 110rpm~140rpm, the diameter of the extrusion head is 1mm~3mm, after heating, it is extruded into the cooling water tank at 25℃~40℃ by the heating extrusion device for cooling, and made into silk Materials, as consumables for 3D printing;

[0037] The second step, 3D printing of intelligent deformable materials:

[0038] Design the structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com