A kind of multi-layer composite film for aseptic filling of liquid food and its preparation process

A multi-layer composite film and aseptic filling technology, applied in packaging, coating, lamination, etc., can solve the problems of low heat sealing temperature, high heat sealing temperature of composite film, poor heat sealing effect, etc., and achieve simple production Convenience, good low temperature heat sealability, good heat sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

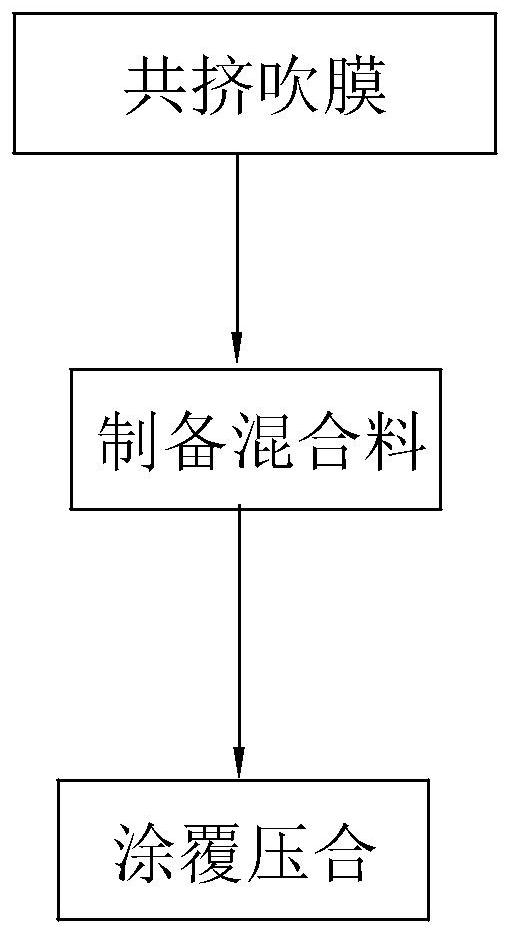

Method used

Image

Examples

Embodiment 1

[0039] Example 1: A multi-layer composite film for aseptic filling of liquid food, the components and their corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0040] Step 1, co-extrusion blown film, put low-density polyethylene, ethylene-vinyl alcohol copolymer and TIE adhesive layer resin into the co-extrusion blown film machine in corresponding parts by weight to obtain a structure of low-density polyethylene / TIE bonded Layer resin / ethylene-vinyl alcohol copolymer / TIE adhesive layer resin / low-density polyethylene base material, the melt index of low-density polyethylene is 2g / 10min, the extrusion resin temperature is 180 ° C, the low-density polyethylene The amount of coating on one side is 10g / m 2 , the thickness of the substrate is 30 μm;

[0041] Step 2, preparing the mixture, melting the metallocene linear low density polyethylene in the corresponding parts by weight, adding the high thermal conductivity filler in the cor...

Embodiment 2-8

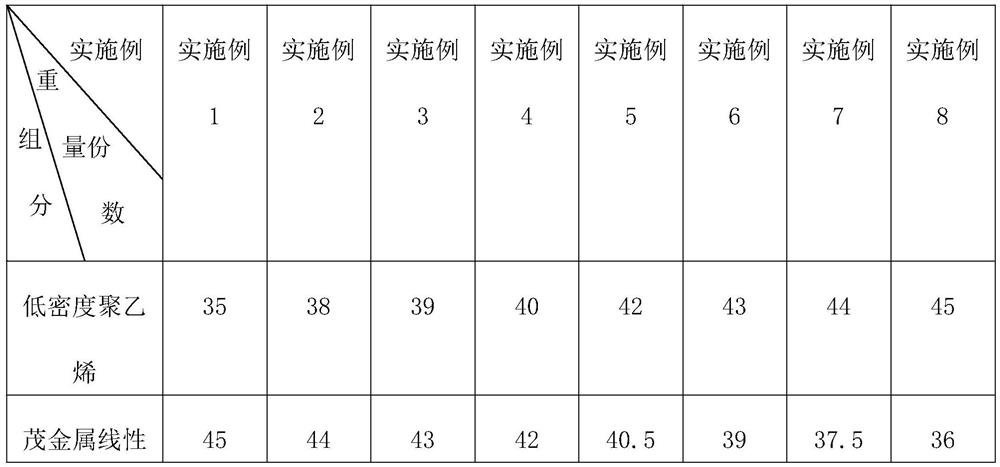

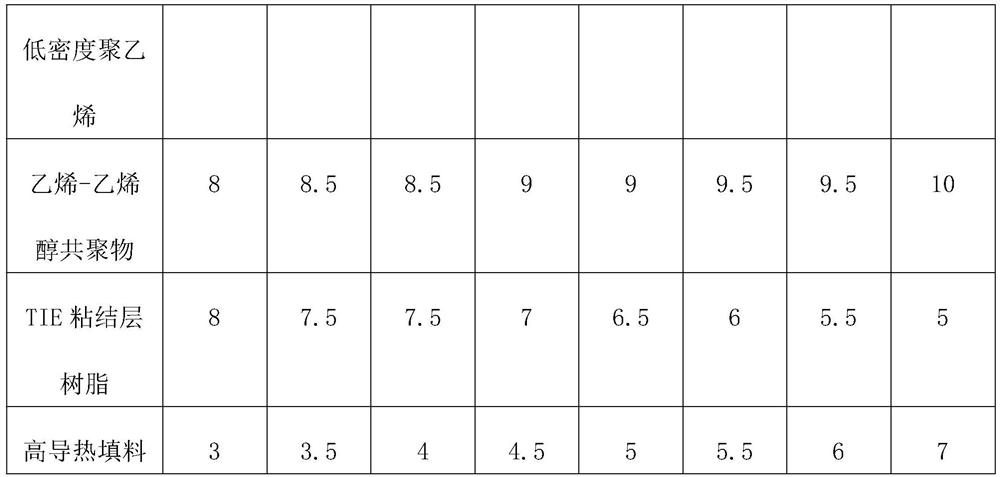

[0044] Example 2-8: A multi-layer composite film for aseptic filling of liquid food. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0045] Each component and parts by weight thereof in table 1 embodiment 1-8

[0046]

[0047]

Embodiment 9

[0048] Embodiment 9: A multilayer composite film for aseptic filling of liquid food. The difference from Embodiment 1 is that the high thermal conductivity filler includes boron nitride and aluminum nitride, and boron nitride and aluminum nitride The ratio of parts by weight is 1:0.7, the particle size of boron nitride is 3 μm under the D50 standard, and the particle size of aluminum nitride is 2 μm under the D50 standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com