Concrete with low slump loss and preparation method thereof

A slump loss, concrete technology, applied in the field of concrete, can solve the problems of large concrete slump loss, long transportation and waiting time, unqualified building strength, etc., to enhance and compensate for poor shrinkage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

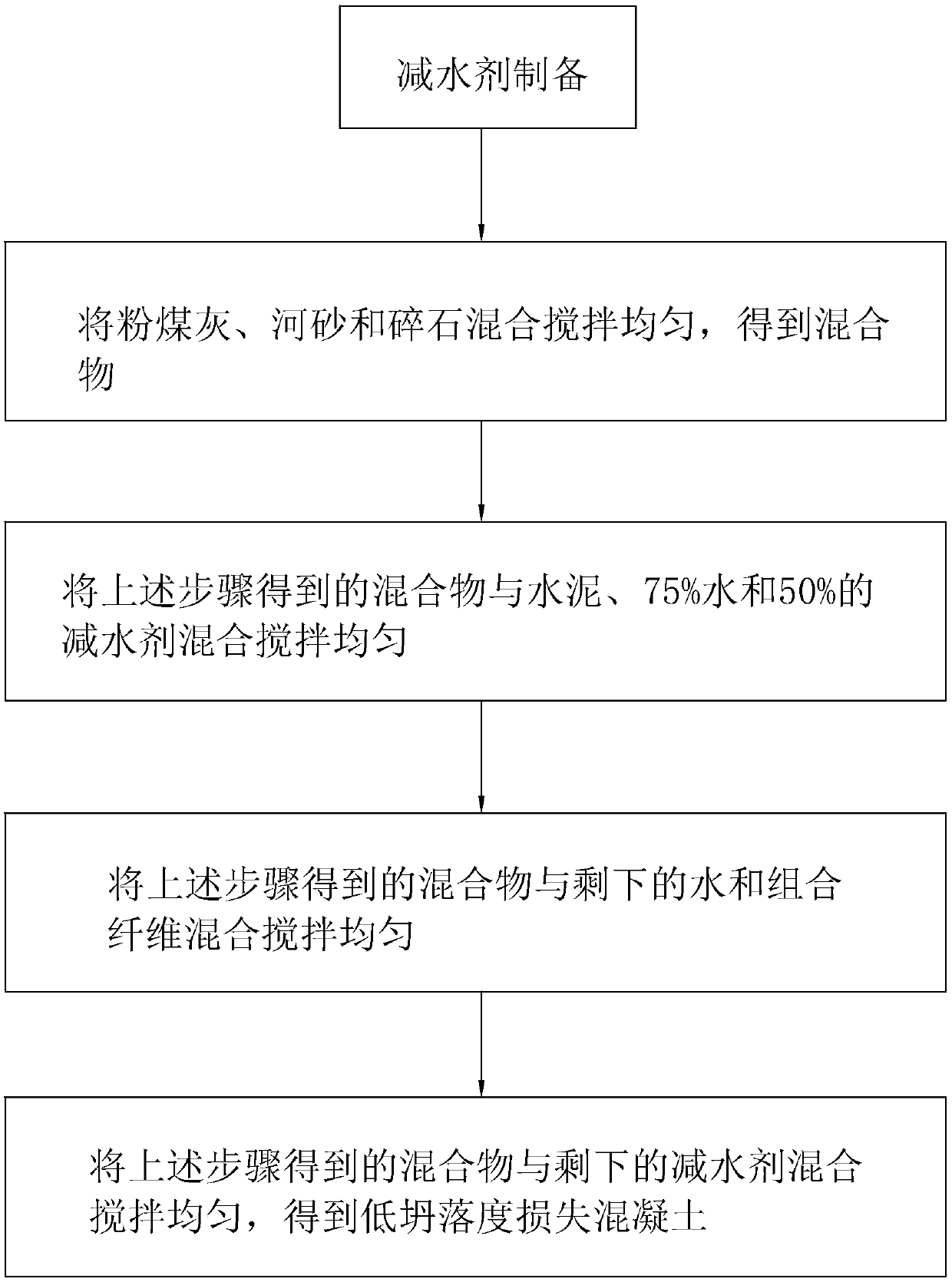

[0039] Embodiment 1: A kind of low slump loss concrete, each component and its corresponding parts by weight are as shown in Table 1, and are prepared through the following steps:

[0040] Step 1, preparation of water reducer: put methallyl polyoxyethylene ether with a molecular weight of 2400, diethyl maleate and water into the reaction kettle, mix well, stir, and then add horse Maleic anhydride, sodium methacryl sulfonate aqueous solution and 3% ammonium persulfate aqueous solution, the maleic anhydride is dripped within 3 hours, the sodium methacrylic sulfonate aqueous solution and ammonium persulfate aqueous solution are dripped within 3.5 hours, and after all the dripping After the addition is complete, keep it warm at 80°C for 1 hour, lower it to room temperature and adjust the pH to 5 with NaOH hot saturated solution to obtain the product;

[0041] Step 2, mixing and stirring the fly ash, river sand and gravel evenly to obtain a mixture;

[0042] Step 3, mixing and sti...

Embodiment 2-6

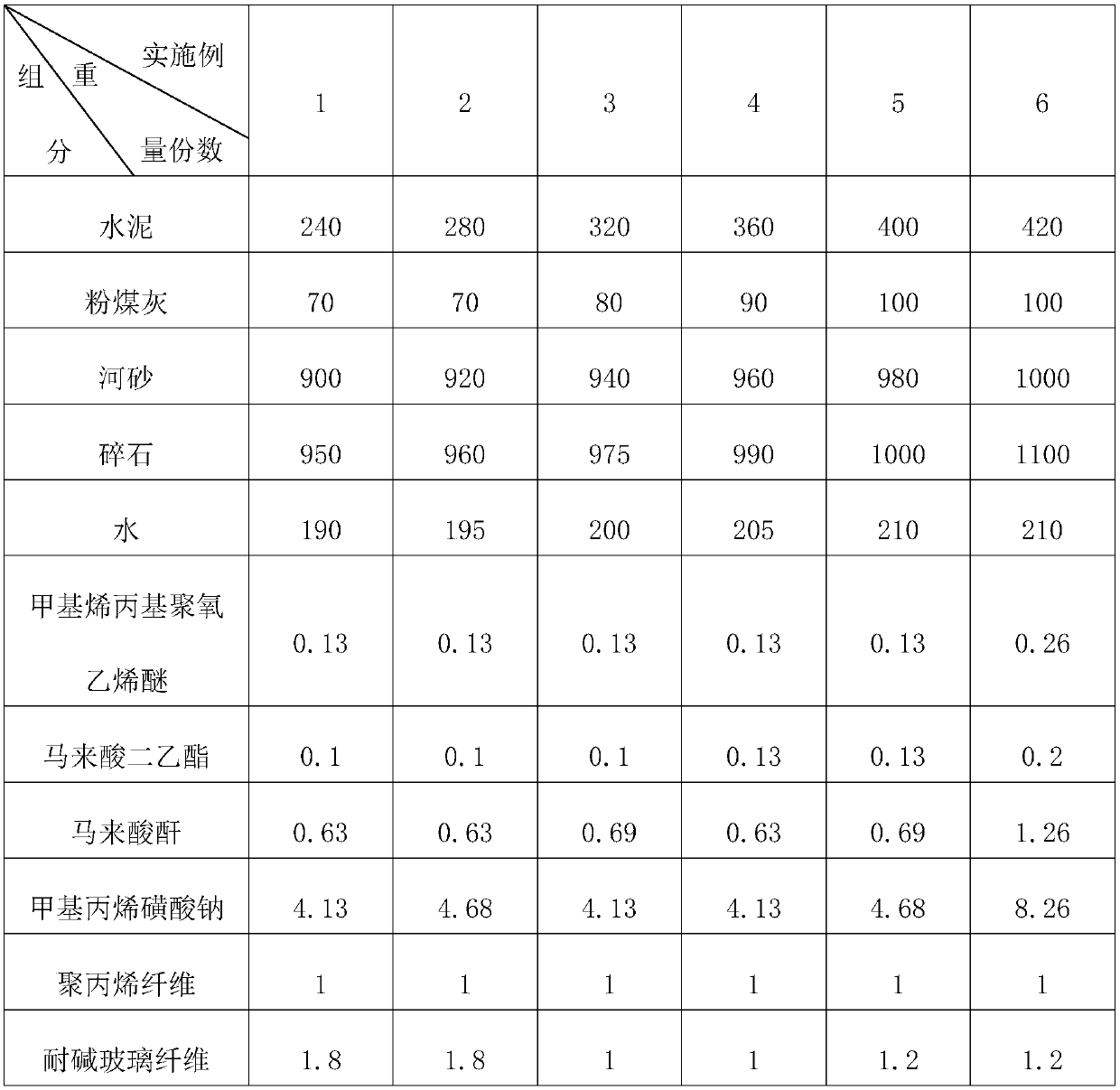

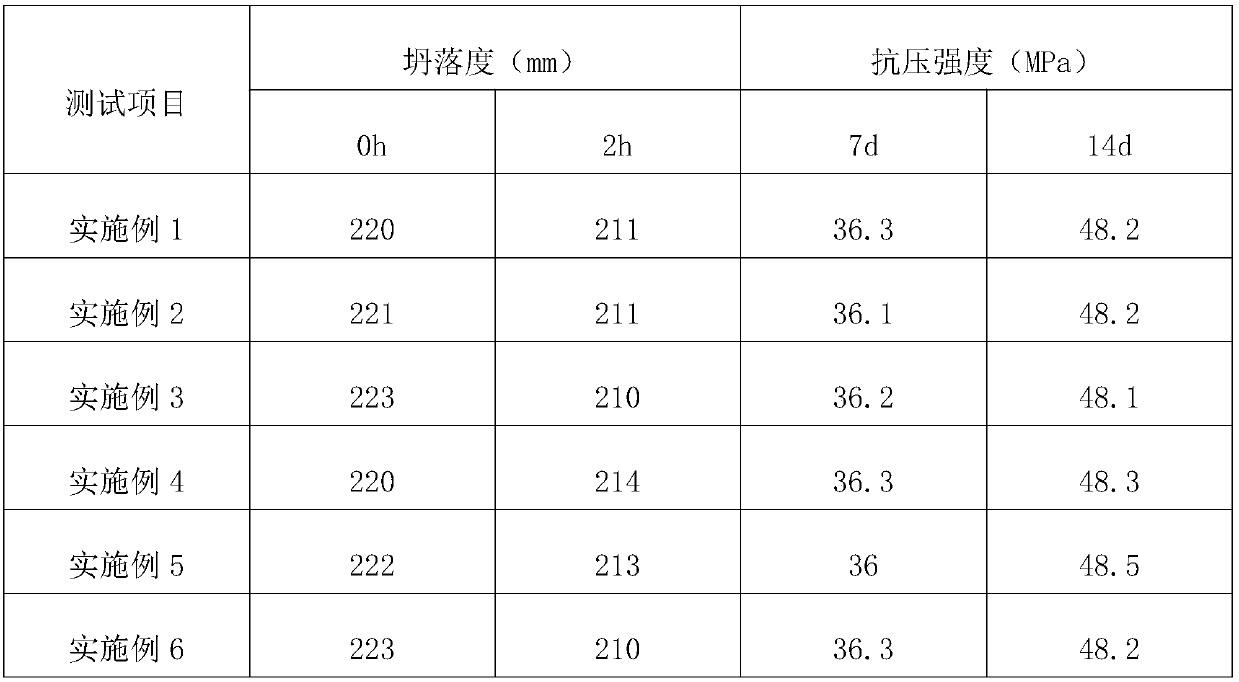

[0045] Example 2-6: a low slump loss concrete, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0046] Each component and parts by weight thereof in table 1 embodiment 1-6

[0047]

Embodiment 7

[0048] Embodiment 7: a kind of preparation method of low slump loss concrete, the difference with embodiment 1 is:

[0049] Step 1, preparation of water reducer: put methallyl polyoxyethylene ether with a molecular weight of 2800, diethyl maleate and water into the reaction kettle, mix well, stir, and then add horse Maleic anhydride, methacrylic sodium sulfonate aqueous solution and 3% ammonium persulfate aqueous solution, the maleic anhydride is dripped within 3.5h, the methacrylic sodium sulfonate aqueous solution and the ammonium persulfate aqueous solution are dripped within 4h, wait until they are all dripped After the addition is complete, keep it warm at 80°C for 1 hour, lower it to room temperature and adjust the pH to 5 with NaOH hot saturated solution to obtain the product;

[0050] It is all identical with embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com